Mechanical autorotating MOCVD (metalorganic chemical vapor deposition) accessory substrate tray

A mechanical, tray technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of inability to ensure the uniform height of the substrate tray, and achieve the effect of avoiding floating above the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

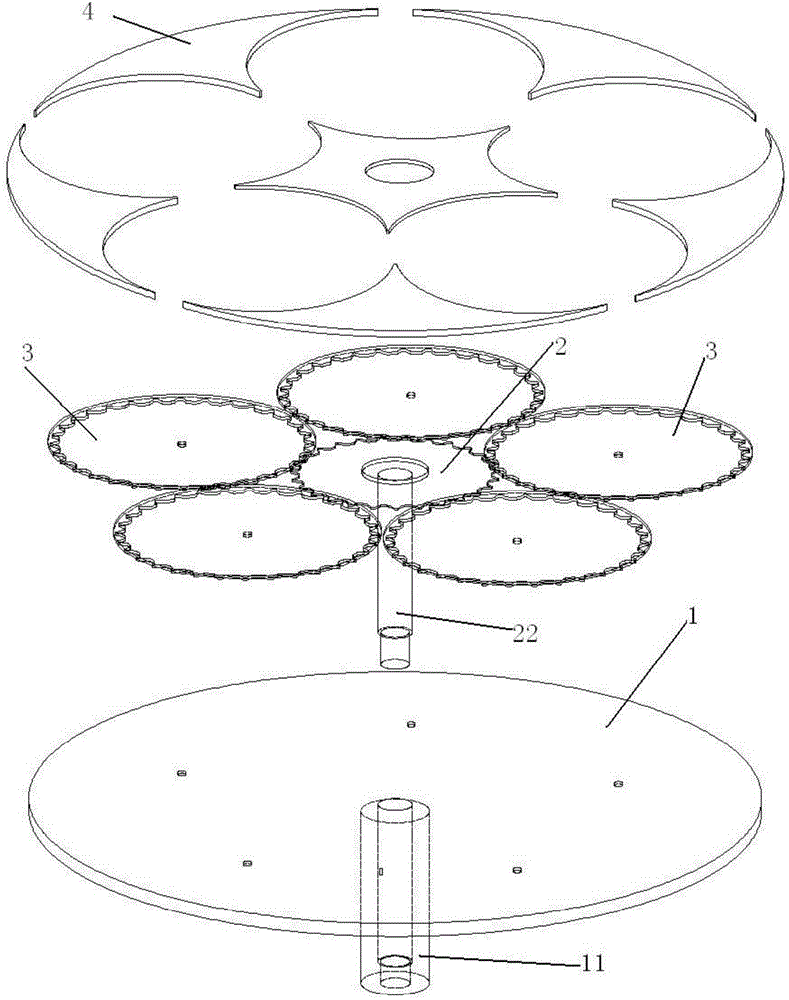

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

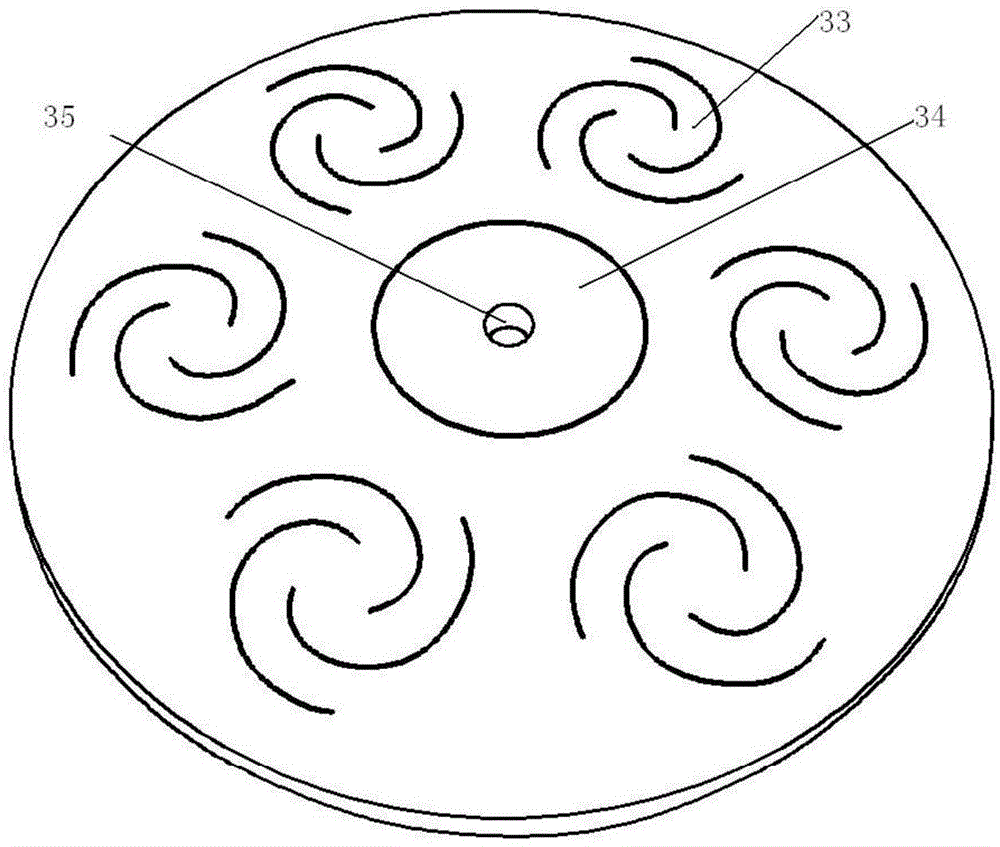

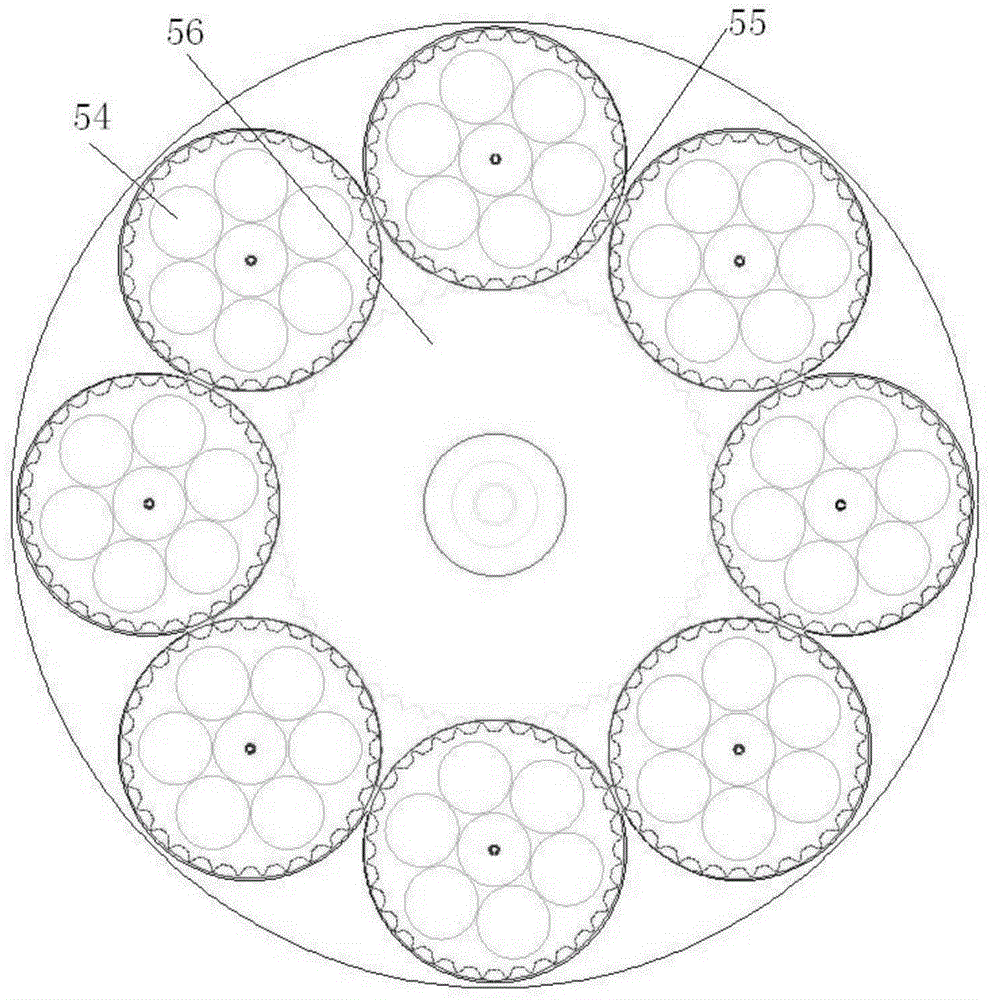

[0027] Such as figure 2 As shown, the mechanical self-rotating MOCVD sub-substrate tray provided by the present invention includes: a substrate placement tray 3 on which a substrate to be deposited by vapor phase is placed. Such as image 3 As shown, a substrate 54 is placed on the substrate holding tray 3 . image 3 A plurality of substrates 54 are arranged in each substrate placement tray 3 in image 3 There are 7 of them.

[0028] Substrate gear 55, such as image 3 As shown, the tooth lines drawn on the edge of the substrate placing tray represent the gears located under the substrate placing tray.

[0029] The substrate gear 55 is fixed below the substrate placement tray 3 . A first driving mechanism, which drives the substrate gear to rotate in a first direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com