Packaging table dust collecting cover

A technology of dust hood and packaging table, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of packaging container pollution, serious lung diseases, time-consuming and labor-intensive, etc., and achieves the effect of reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

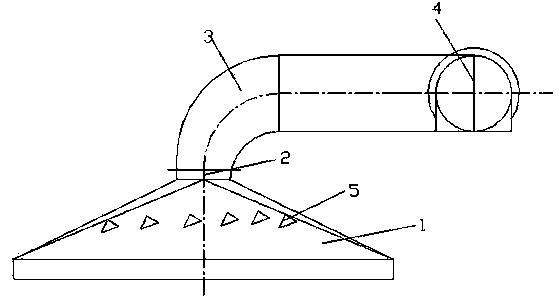

[0013] Embodiment 1: as figure 1 As shown, a vacuum cover for a packaging table includes an umbrella-shaped cover body 1, a connecting pipe 2 is provided on the top of the cover body 1, and a dust suction pipe 3 is connected to the outlet of the connecting pipe 2. The dust pipe 3 is externally connected with a dust suction pump 4; a spray device 5 is arranged inside the cover body 1; the inclination of the slope of the umbrella-shaped cover body 1 is 25-35°.

[0014] The shower device 5 is arranged at the middle part of the inner wall of the umbrella-shaped cover body 1 .

[0015] There are 8 spray devices 5 and they are evenly distributed on the inner wall of the umbrella-shaped cover body 1 and on the same level.

[0016] A rotating device capable of rotating 180° is connected between the spraying device 5 and the inner wall of the umbrella-shaped cover 1 .

[0017] When in use, the excess dust is sucked away in time by the dust suction pump 4; then after the packaging is ...

Embodiment 2

[0018] Embodiment 2: basically the same as Embodiment 1, the difference is that there are six spraying devices 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com