Dust removal structure in sealed cabin for additive manufacturing

A technology of additive manufacturing and sealed cabin, which is applied in the field of additive manufacturing machines, can solve the problems that affect the additive work, smoke and splashes cannot be sucked away, and achieve good collection effect and reduce the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

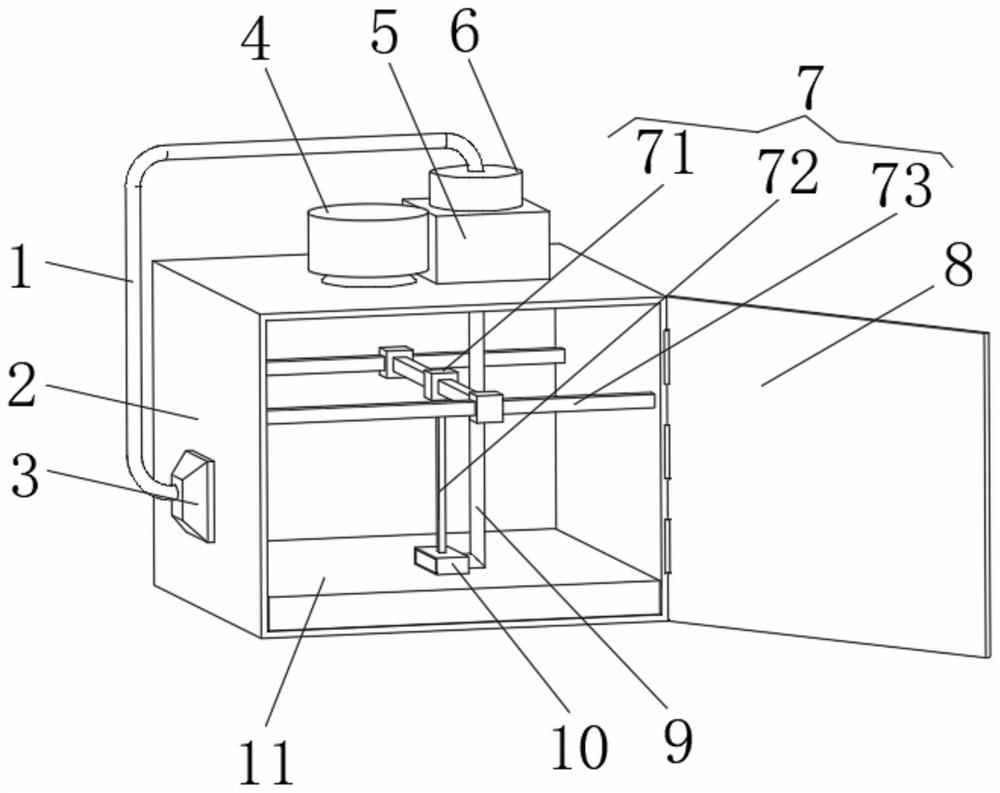

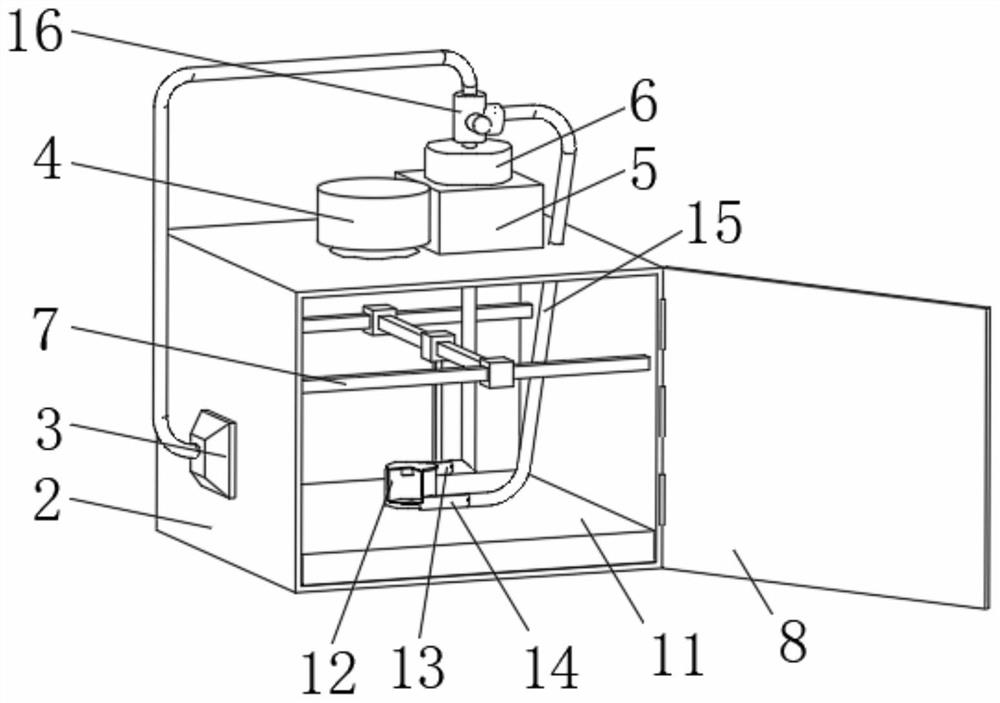

[0028] Example 1: Please refer to figure 1 , image 3 and Figure 4 , this embodiment discloses a dust removal structure in a sealed cabin for additive manufacturing, which includes a hollow box body 2 and a moving support 7. The front side of the box body 2 is provided with an operation opening that communicates with the inside and outside of the box body. An opening and closing box door 8 is installed on the operation opening, a processing and forming platform 11 is provided on the bottom side of the inner cavity of the box body 2, and an air intake cover is installed in the inner cavity of the box body 2 through the moving support member 7 10. The horizontal position of the air intake cover 10 is adjustable. The air intake cover is provided with a suction port connecting the inside and outside of the air intake cover. The upper side of the box body 2 is provided with a mounting hole, and a laser generator is installed in the mounting hole. device 4, and the box body 2 is ...

Embodiment 2

[0038] Embodiment two: if figure 1 As shown, this embodiment discloses a dust-removing structure in a sealed cabin for additive manufacturing. A second linear motor 73 installed in parallel on the inner wall of the box body 2, a first linear motor 71 is installed between the movers of the two second linear motors 73, and the mover of the first linear motor 71 It is fixedly connected with the upper end of the vertical rod 72 , and the lower end of the vertical rod 72 is fixedly connected with the outer side of the air intake cover 10 .

[0039] The controller of the additive manufacturing machine controls the first linear motor 71 and the second linear motor 73 to work; the first linear motor 71 and the second linear motor 73 drive the intake cover 10 to move horizontally through the vertical rod 72, so that the intake cover 10 Real-time tracking close to the heat source action area and close enough.

Embodiment 3

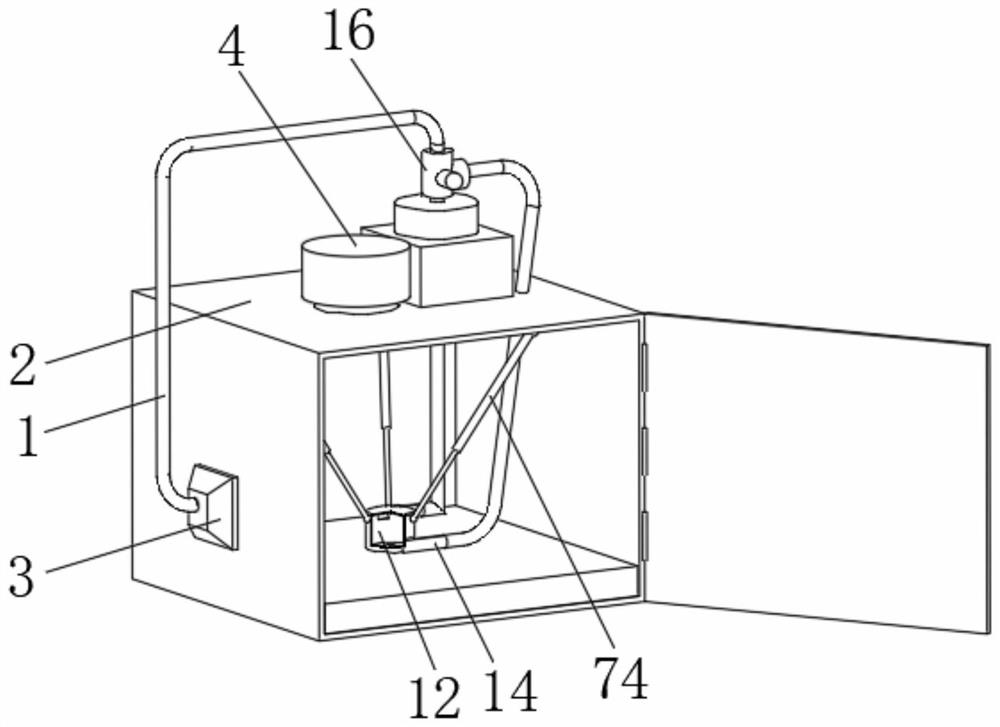

[0040] Embodiment three: as image 3 As shown, this embodiment discloses a dust-removing structure in a sealed cabin for additive manufacturing. There are less than three electric telescopic rods 74, the upper end of the electric telescopic rod 74 is rotatably connected to the upper side of the inner cavity of the box body 2, and the lower end of the upper end of the electric telescopic rod 74 is connected to the outer side of the air intake cover 10 Rotational connection; the controller of the additive manufacturing machine separately controls the electric telescopic rods 74 to work together, so that the air intake cover 10 can track and approach the heat source action area in real time and is close enough, and the electric telescopic rods 74 work together to control the air intake cover 10 to move on a horizontal plane. Common means in the prior art, and the height adjustment of the air intake cover 10 is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com