Ultra-precise three-axis association micro-milling device with micro-tool monitoring capacity

A three-axis linkage, ultra-precise technology, applied to fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problem of difficult real-time observation and monitoring of processed surface quality, reduce the laser damage threshold of KDP crystals, shorten the service life of crystals, etc. problems, to achieve the effect of clear and reasonable cable layout, compact structure, and reduced structural size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

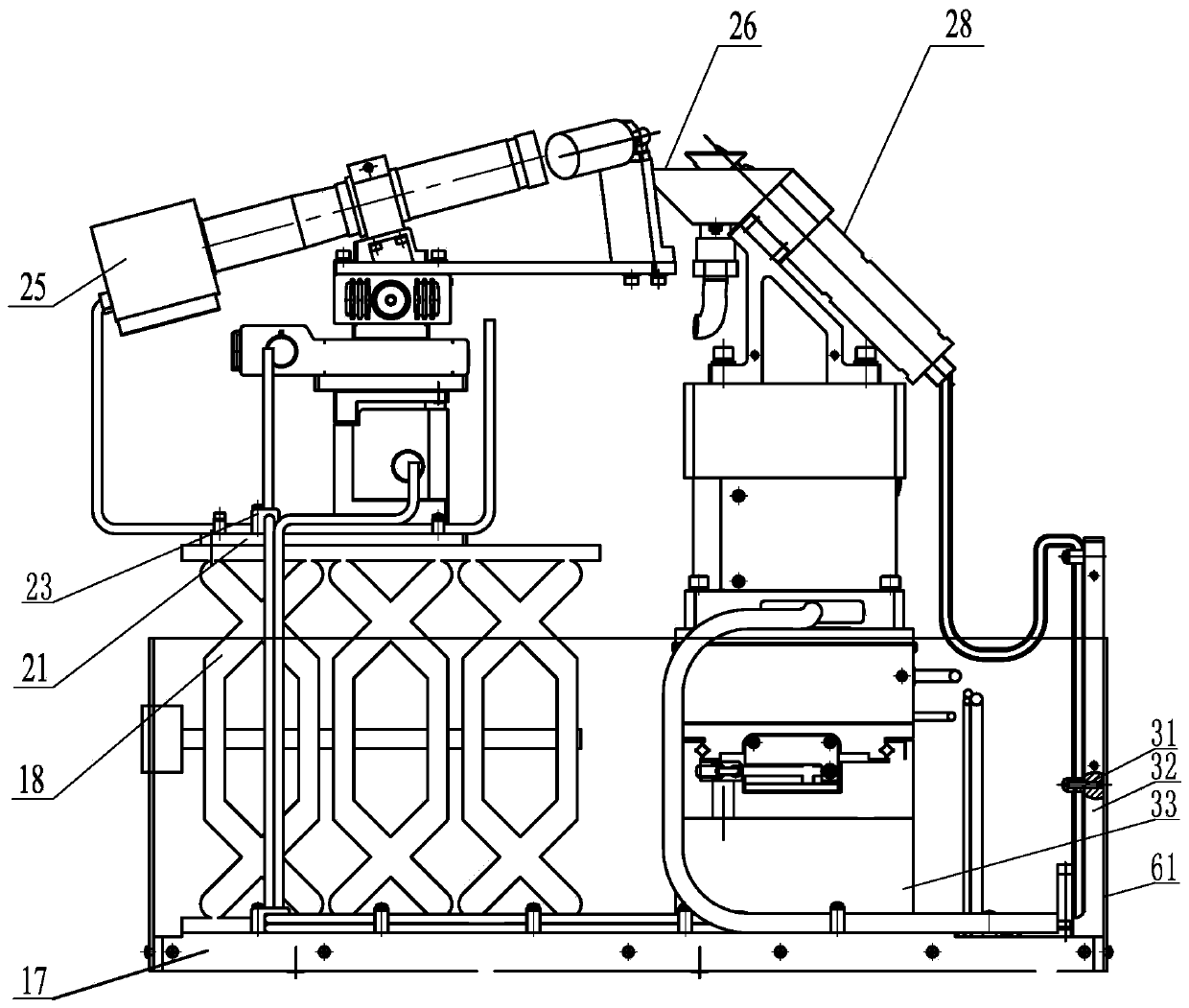

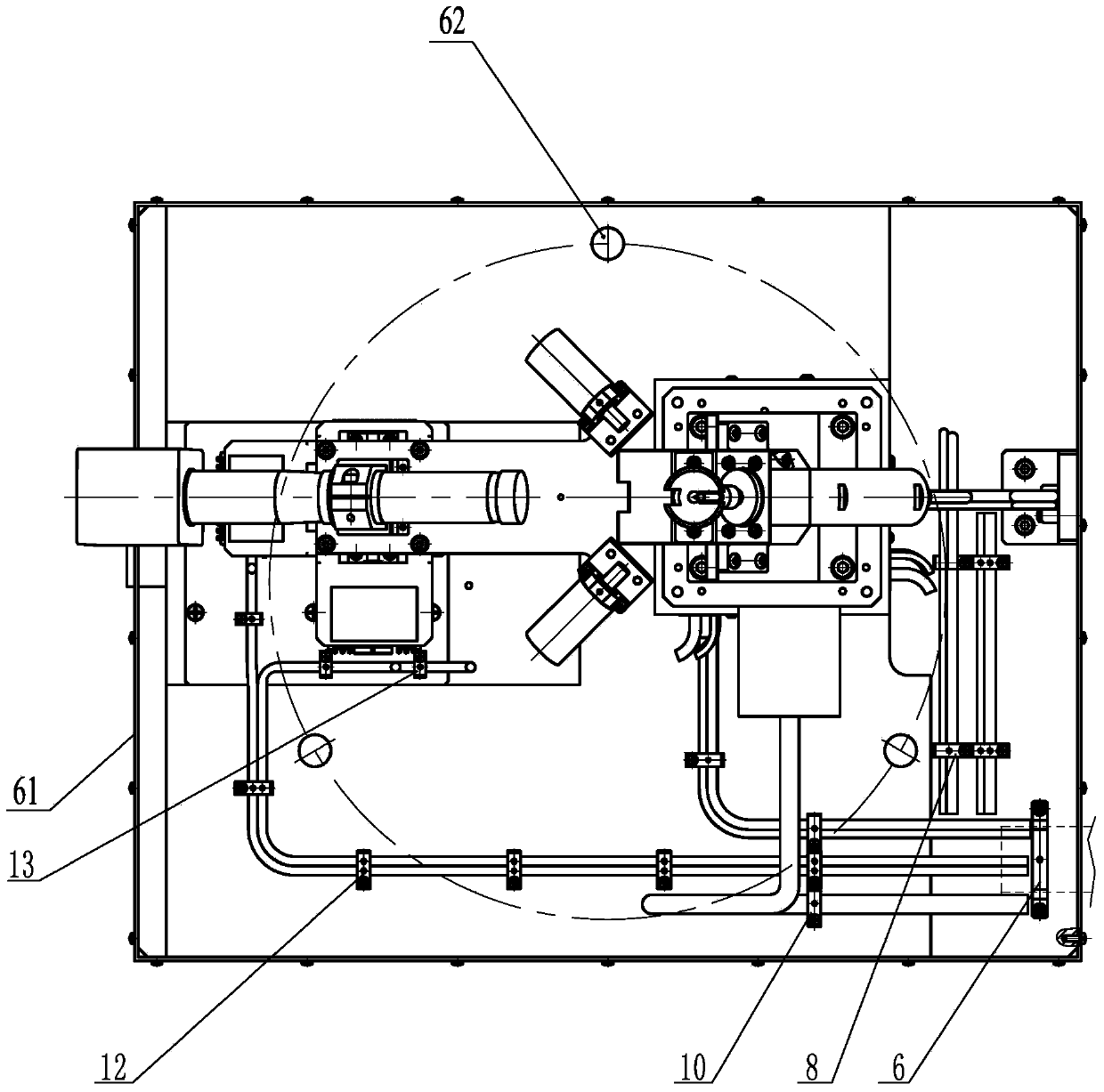

[0017] Specific implementation mode one: combine Figure 1 to Figure 14 Explain, an ultra-precision three-axis linkage micro-milling device with micro-tool monitoring capability in this embodiment, the ultra-precision three-axis linkage micro-milling device with micro-tool monitoring capability includes a bottom mounting plate 17, a manual lifting adjustment platform 18 , Microscope connection plate 21, tool microscope moving platform 25, chip collection assembly 26, tool three-axis linkage platform 28, tool moving part wiring board 32 and tool moving part pad 33;

[0018] The tool moving part wiring board 32, the tool moving part cushion block 33 and the manual lifting adjustment platform 18 are all fixed on the upper end surface of the bottom mounting plate 17, and the bottom mounting plate 17 is processed with three connecting holes 62 along its thickness direction, and the three connecting holes 62 are evenly distributed on the same circumference (for installing the device...

specific Embodiment approach 2

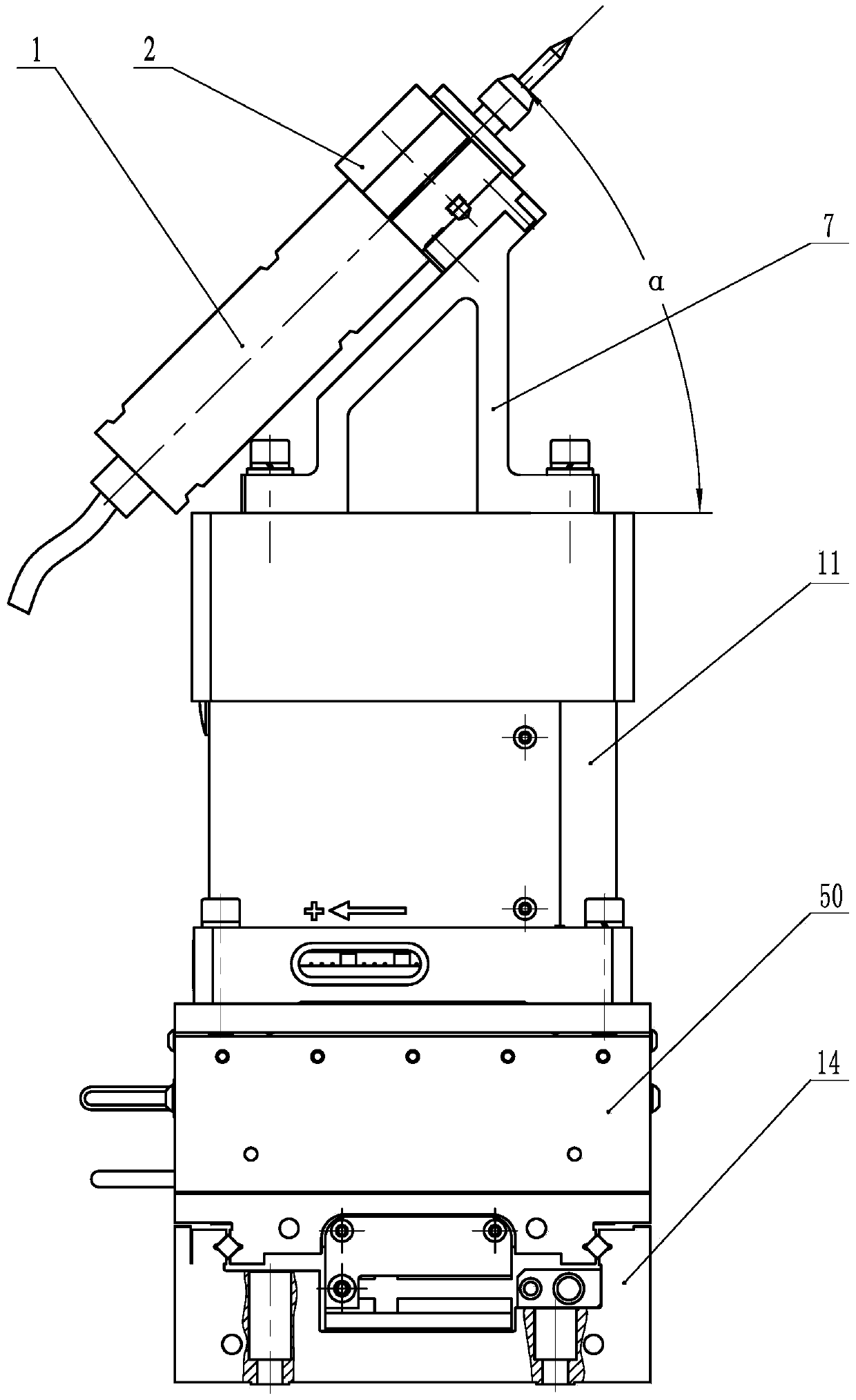

[0020] Specific implementation mode two: combination figure 1 and image 3 Note that the tool three-axis linkage platform 28 in this embodiment includes an electric spindle 1, an electric spindle fixture 2, a Z-axis connector 7, a tool movement Z-axis unit 11, a tool movement Y-axis unit 50, and a tool movement X-axis unit 14; The Z-axis connector 7, the tool movement Z-axis unit 11, the tool movement Y-axis unit 50, and the tool movement X-axis unit 14 are sequentially connected from top to bottom, and the electric spindle fixture 2 is located on the Z-axis connector 7 and the two are connected. , the electric spindle 1 is arranged in the electric spindle fixture 2, and the electric spindle 1 is clamped and fixed by the electric spindle fixture 2.

[0021] The tool three-axis linkage platform 28 realizes the high-speed rotation of the micro-milling tool and the high-precision three-axis linkage of the micro-milling tool through the high-speed rotation of the electric spindle...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 , Figure 7 and Figure 8 Note that the tool microscope moving platform 25 in this embodiment includes a light source connecting plate 51, a tool microscope Z-axis unit 54, a tool microscope rail connector 55, a tool microscope XY axis unit 56, a fixture connector 16, a monitoring microscope 63, and a tool microscope Fixture 19 and two light source assemblies, each light source assembly includes light source support 5, light source fixture 52 and CCS point light source 53; fixture connector 16, light source connection plate 51, tool microscope XY axis unit 56, tool microscope rail connector 55 and the tool microscope Z-axis unit 54 are sequentially connected from top to bottom, the tool microscope fixture 19 is fixed on the fixture connector 16, and the monitoring microscope 63 is installed in the tool microscope fixture 19 and fixed by the tool microscope fixture 19. The two light source supports 5 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com