Shoemaking injection molding machine

An injection molding machine and injection mold technology, which is used in household components, household appliances, other household appliances, etc., to achieve physical and mental health protection, shorten cooling time, and be beneficial to environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

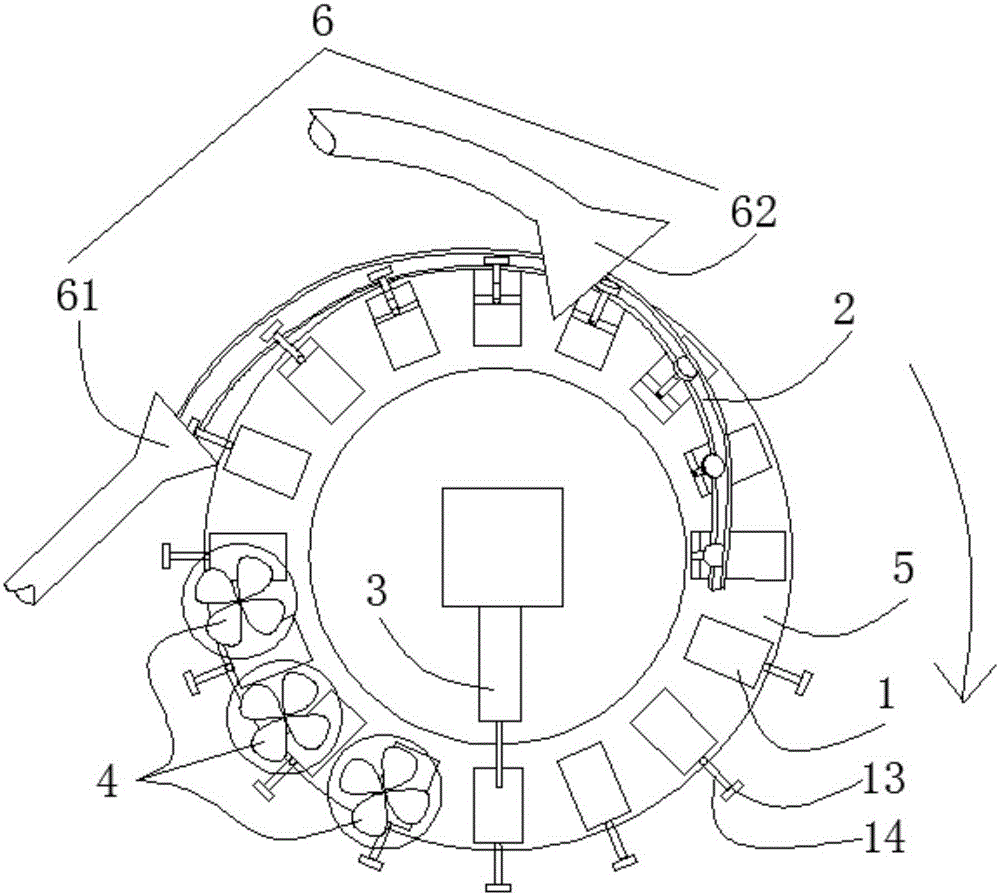

[0023] Such as figure 1 As shown, an injection molding machine for shoemaking, the injection molding machine includes an injection mold 1, an arc track 2, an injection device 3, a cooling device 4, a rotary table 5, an exhaust device 6, and a mold opening mechanism.

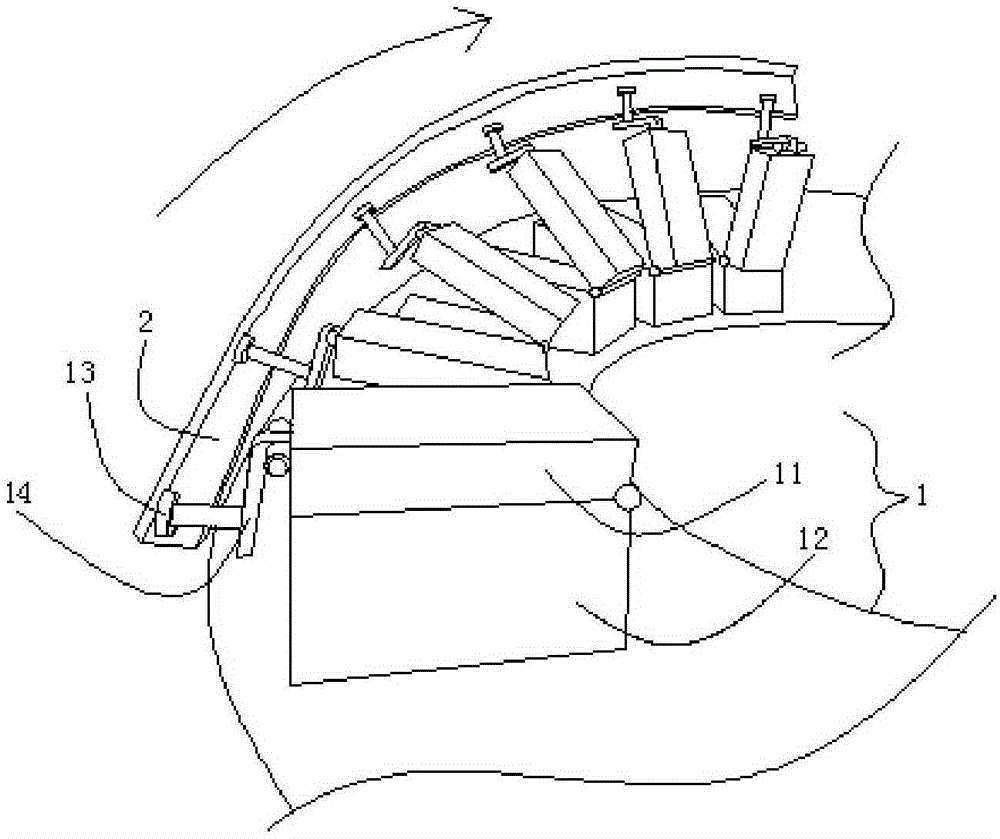

[0024] Such as figure 2 As shown, the injection mold 1 includes an upper mold 11 and a lower mold 12 . One end of the upper mold 11 is hinged to one end of the lower mold 12, and the other end of the upper mold 11 is an open end. Around the rotating workbench 5, several molds are annularly placed, and the hinged end of the mold is towards the center of the circle of the workbench 5. The mold opening mechanism includes a section of arc track 2 and a turning roller 13;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com