Deburring device

A deburring and equipment technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve problems such as difficulty in removing burrs, bruised processing surfaces, waste of labor, etc., to reduce cleaning workload and efficiency. The effect of improving and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

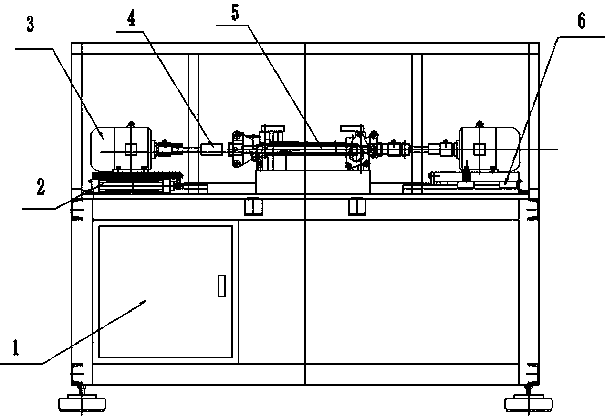

[0013] In the present invention, an electrical cabinet 1 is arranged at the lower part of the frame to control the operation of the motor 3. The motor 3 is arranged on the track 2 through the track connecting groove 6, and can move back and forth along the track 2; therefore, it can drive the hole brush 4 connected to it to move back and forth , and the hole brush 4 can be driven by the motor 3 to rotate, thereby forming a spiral motion curve to remove the burr in the hole of the workpiece.

[0014] The workpiece 5 of the present invention is fixed by a clamp, and its height is adjustable up and down, so that it corresponds to the position of the hole brush 4 .

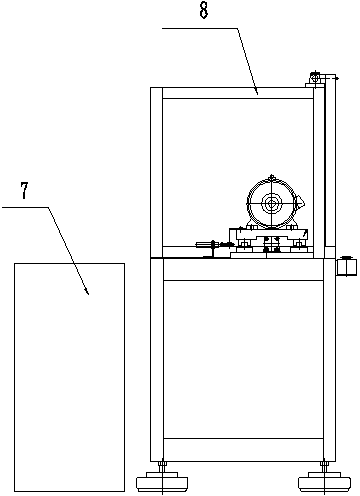

[0015] The present invention is equipped with a dust suction device 7, and at the same time that the equipment removes burrs, the dust suction device 7 is turned on to suck away the burrs in time, preventing the accumulation of burrs from affecting the neatness of the equipment, or blocking the work of the hole brush 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com