Plate-type fume exhauster

A range hood, plate-type technology, applied in the field of plate range hoods, can solve the problems of poor smoke absorption effect, inconvenient cooking of the range hood, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

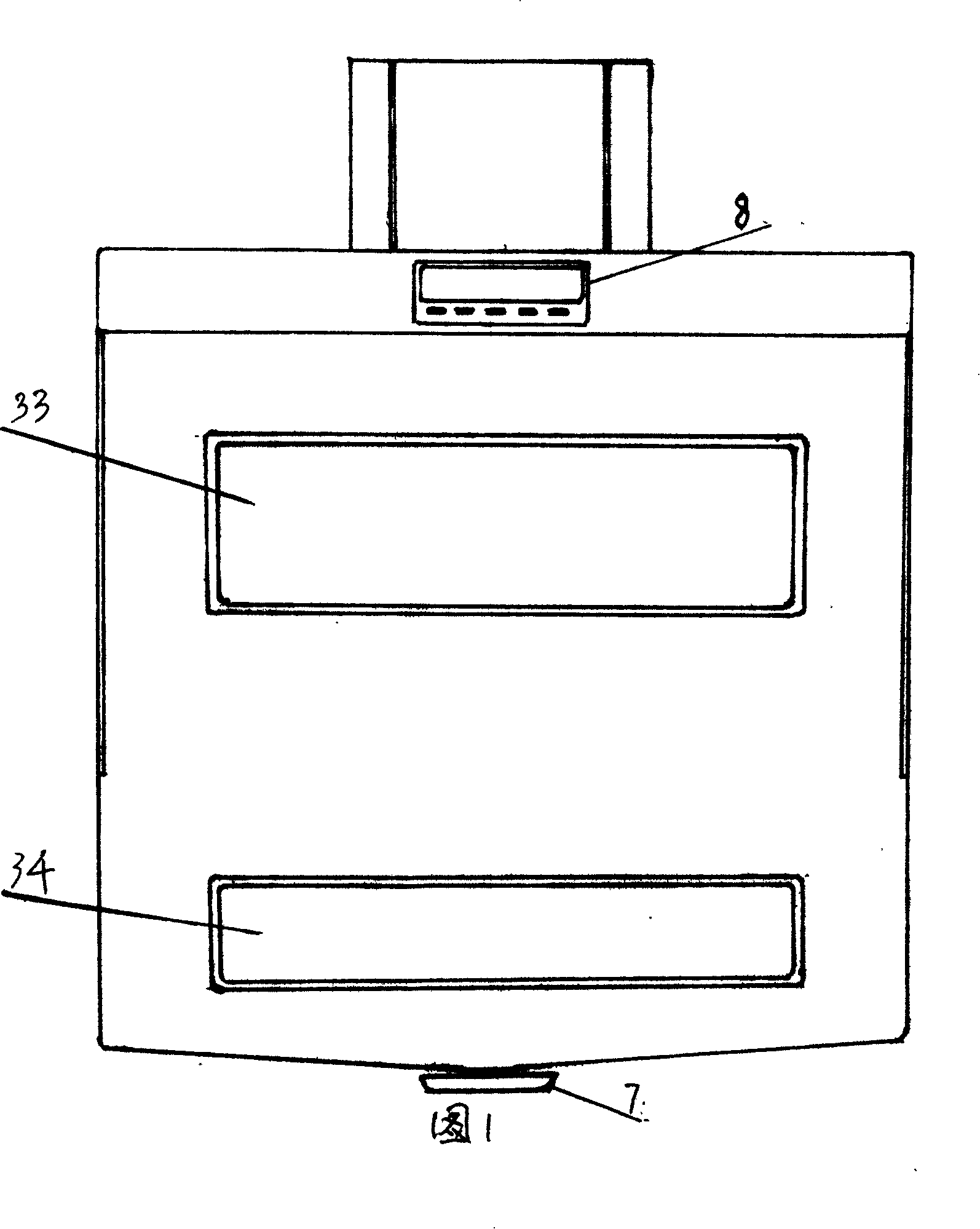

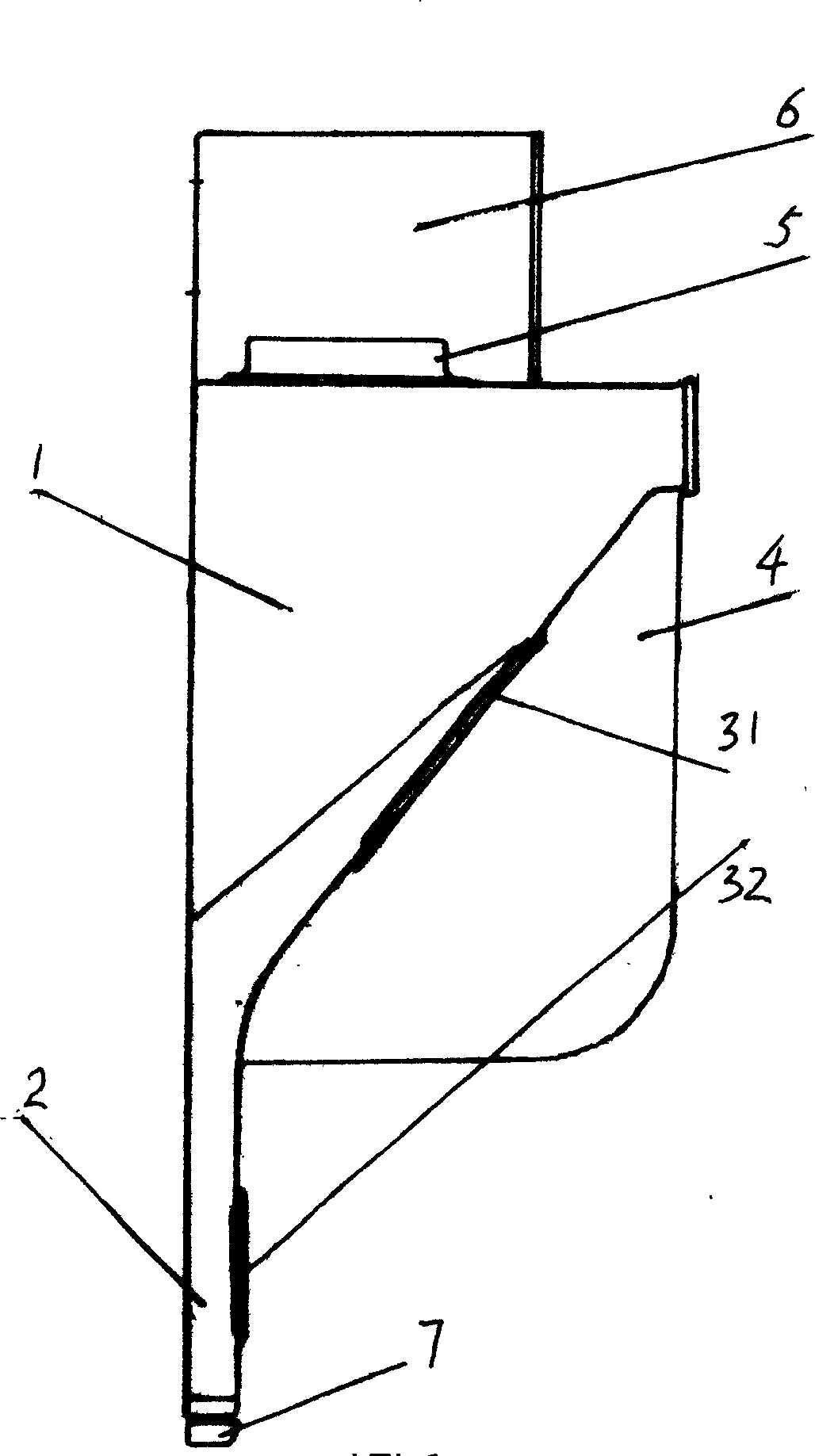

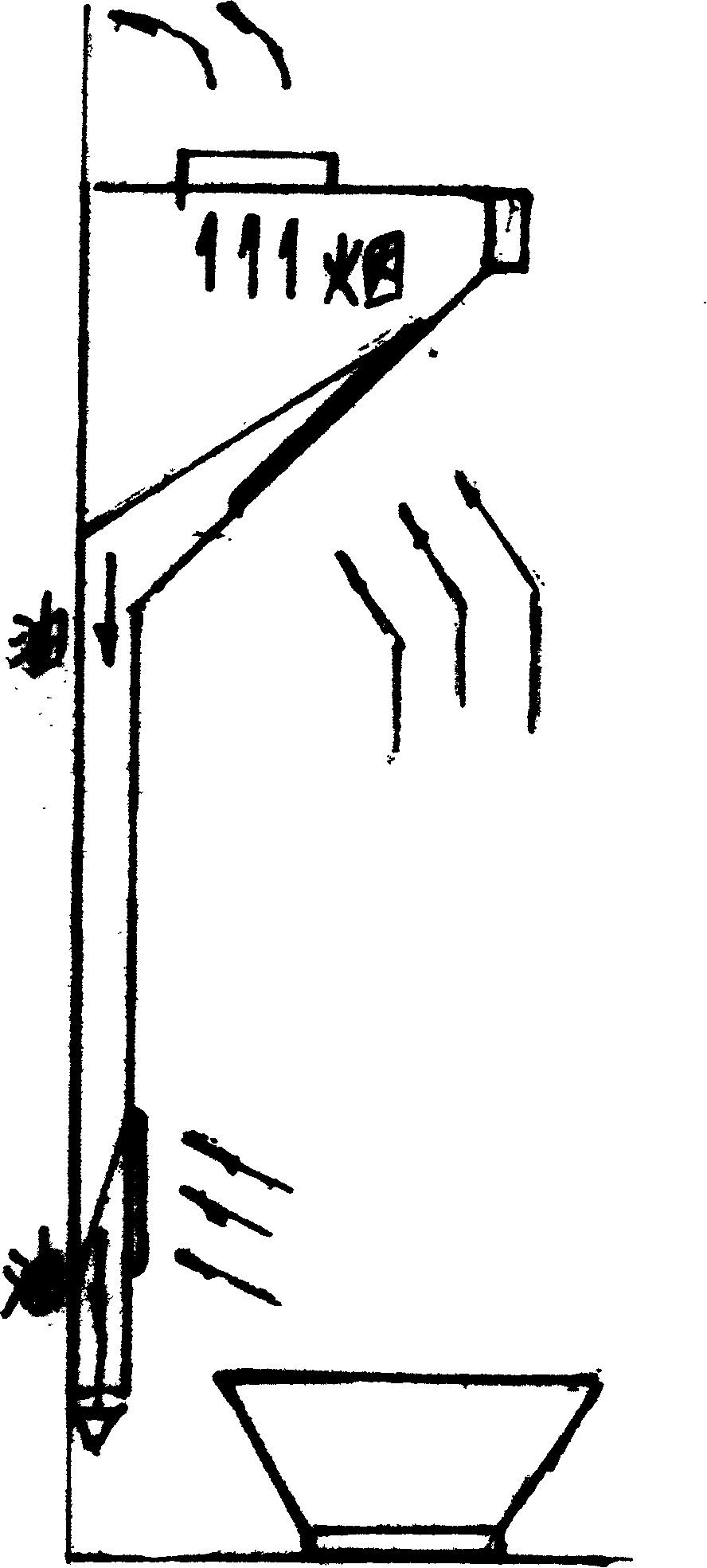

[0007] Specific embodiment: this plate-type range hood of the present invention has a blower fan and a flue exhaust duct communicated with the blower fan. The exhaust duct is a corner-shaped box body 1, and the box body also has a downwardly extending passage 2. The top of the box body has an outlet 5 communicated with the fan, and the outlet 5 communicates with the fan outside the wall through the flow channel 6. The front of the casing main body is an inclined surface, and the smoking ports 31, 32 are just arranged on the inclined surface of the casing and in front of the downwardly extending passage. The two smoking ports are respectively provided with oil fume separators 33 and 34 . The bottom end of the passage extending downwards has an oil discharge port arranged and an oil storage box 7 is attached. The upper end of the casing has a control button and a light control panel 8. In this plate-type range hood of the present invention, the box body can be conveniently arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com