Mixed type vertical circulation ITG (intelligent three-dimensional garage)

A vertical circulation and three-dimensional garage technology, applied in the field of garages, can solve problems such as potential safety hazards, increased user waiting time, and easy shaking of the car-carrying basket, so as to achieve the effect of vehicle operation balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

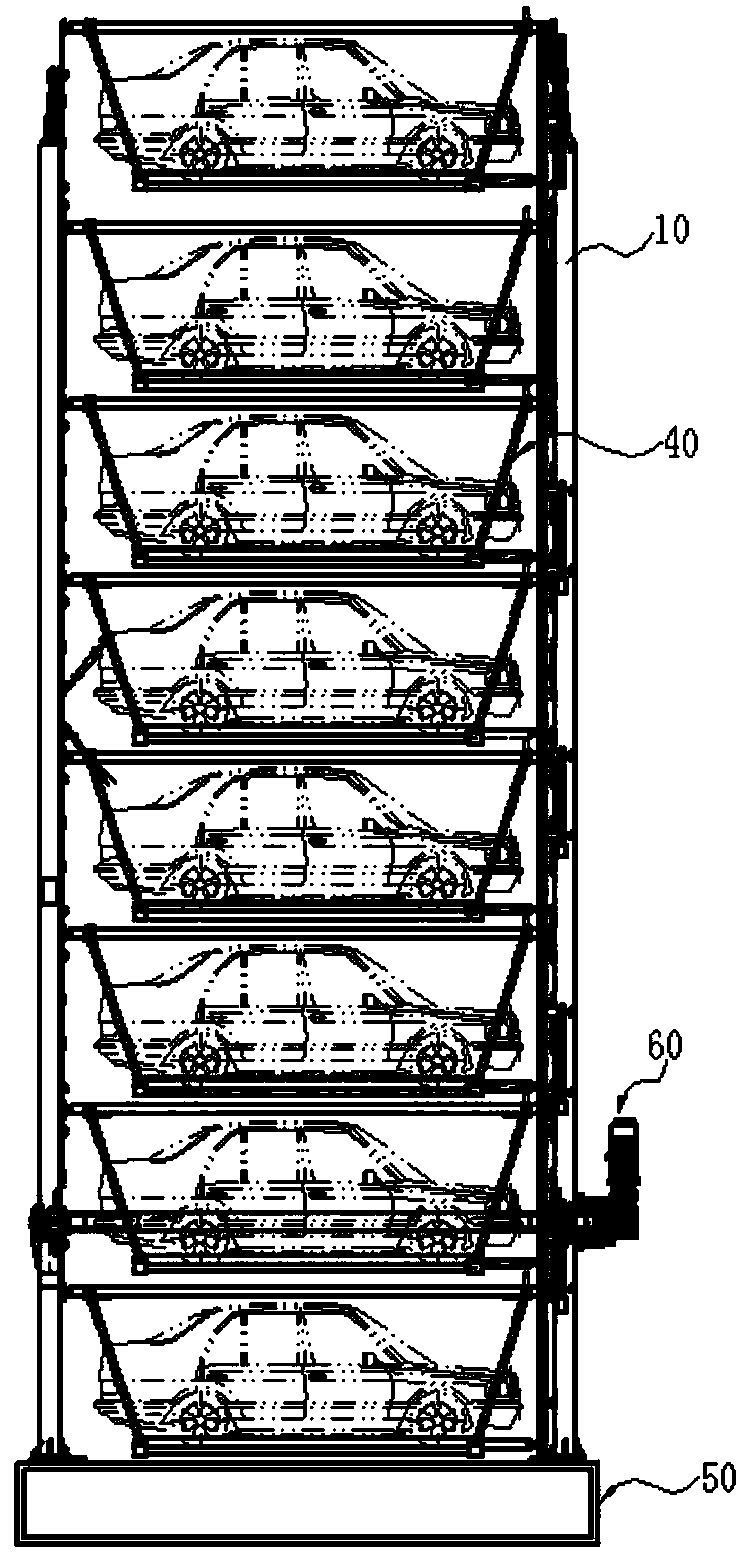

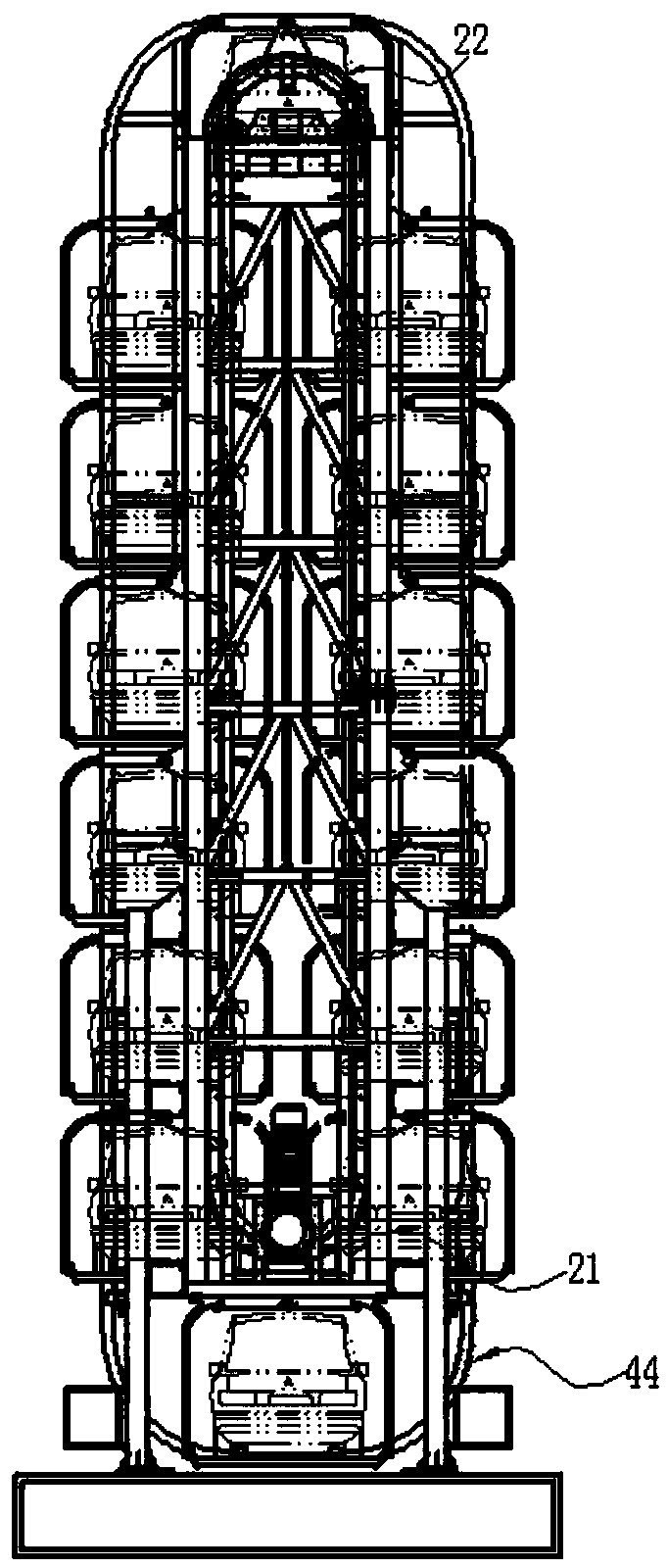

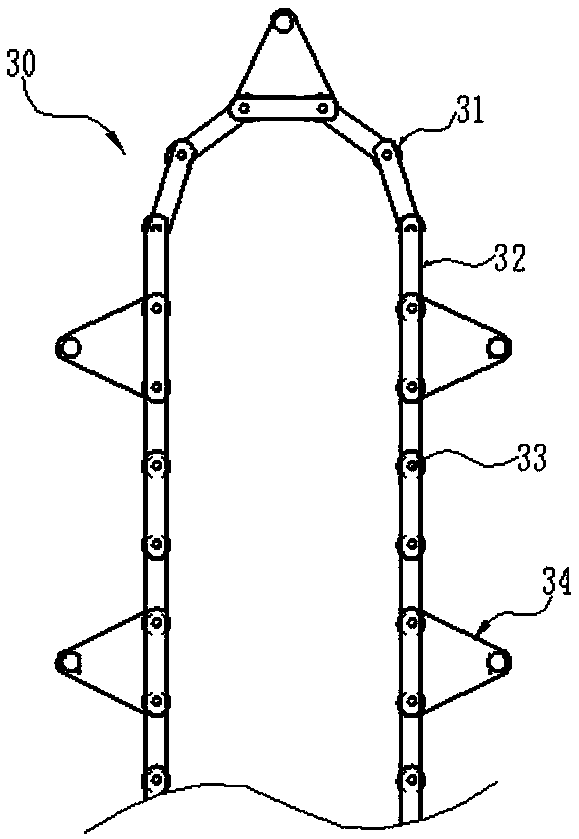

[0025] Such as figure 1 with figure 2 As shown, a hybrid vertical circulation intelligent three-dimensional garage includes a frame assembly and a drive assembly 60. The frame assembly includes two relatively vertically arranged frame plates 10, and drive wheels are respectively arranged to rotate at both ends of the frame plate 10. , the driving wheel is driven and arranged with a lifting chain 30 via the drive assembly 60, and the lifting chain 30 is arranged with a car-carrying basket 40 for placing a car at intervals. In this application, when the equipment is in operation, the pulleys on the car-carrying basket 40 Running in the guide groove 44, the connecting beam 35 at the lower part is provided with a cushion support 45 to straighten and straighten the carriage 41 close to its upper part, so that the vehicle-carrying baskets 40 at the straight line section of the guide groove 44 are superimposed on each other and corrected each other. Make the vehicle more balanced a...

Embodiment 2

[0030] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that it also includes an anti-sway device for entering and leaving the warehouse, and the anti-swaying device for entering and leaving the warehouse includes an electromagnet device located on the foundation 50 , when the hybrid vertical circulation intelligent three-dimensional garage receives the order to stop and pick up the car, the car-carrying basket 40 moves to the middle position of the lower end, the parking sensor triggers the motor to stop and brake, the anti-shake device for entering and exiting the warehouse receives a signal and powers on, and the electromagnet 71 bounces. Lifting and adsorbing on the carriage 41, the front, rear, left, and right positions of the carriage 41 are fixed through the fixing groove 72, so that the carriage 41 does not shake when the car goes in and out of the war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com