Moving die plate of injection molding machine and injection molding machine

A mobile template and injection molding machine technology, applied in the field of injection molding machines, can solve problems such as unreasonable layout of machine hinge joints, increase the weight of mobile templates, increase the amount of matrix materials, etc., to reduce the application of materials, reduce weight, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

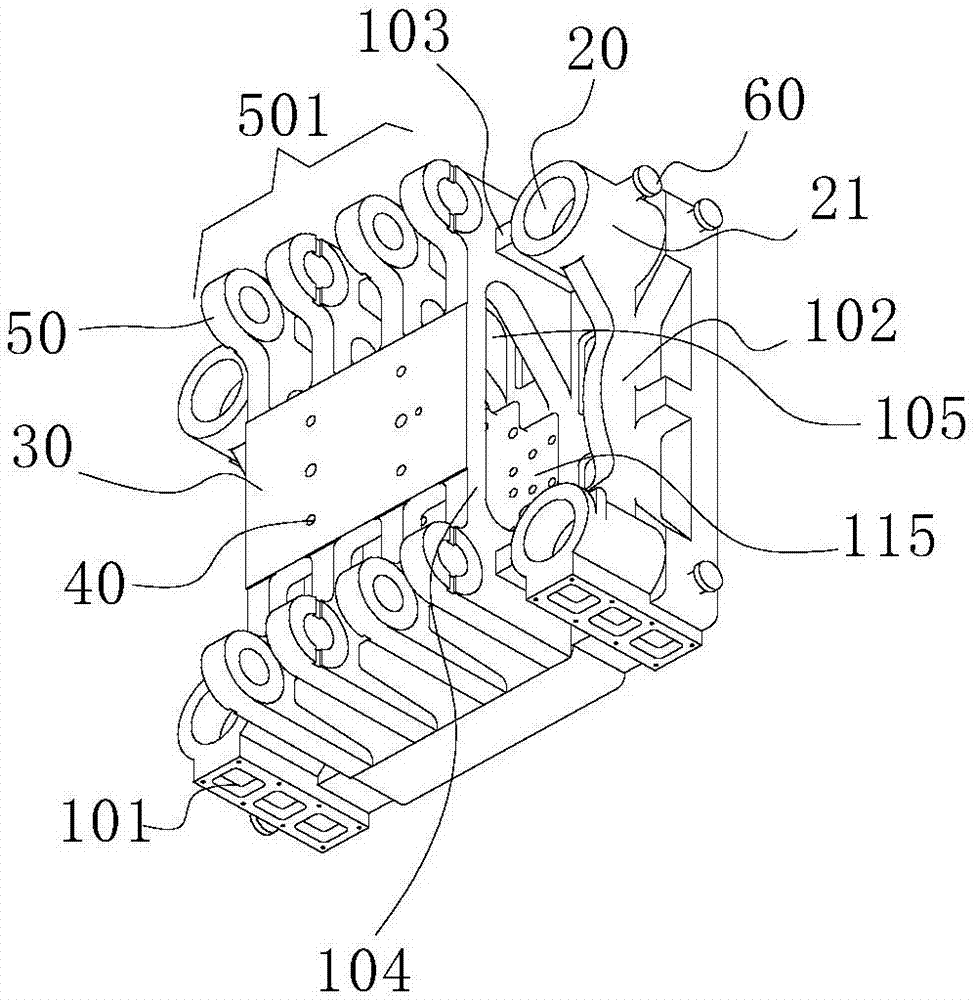

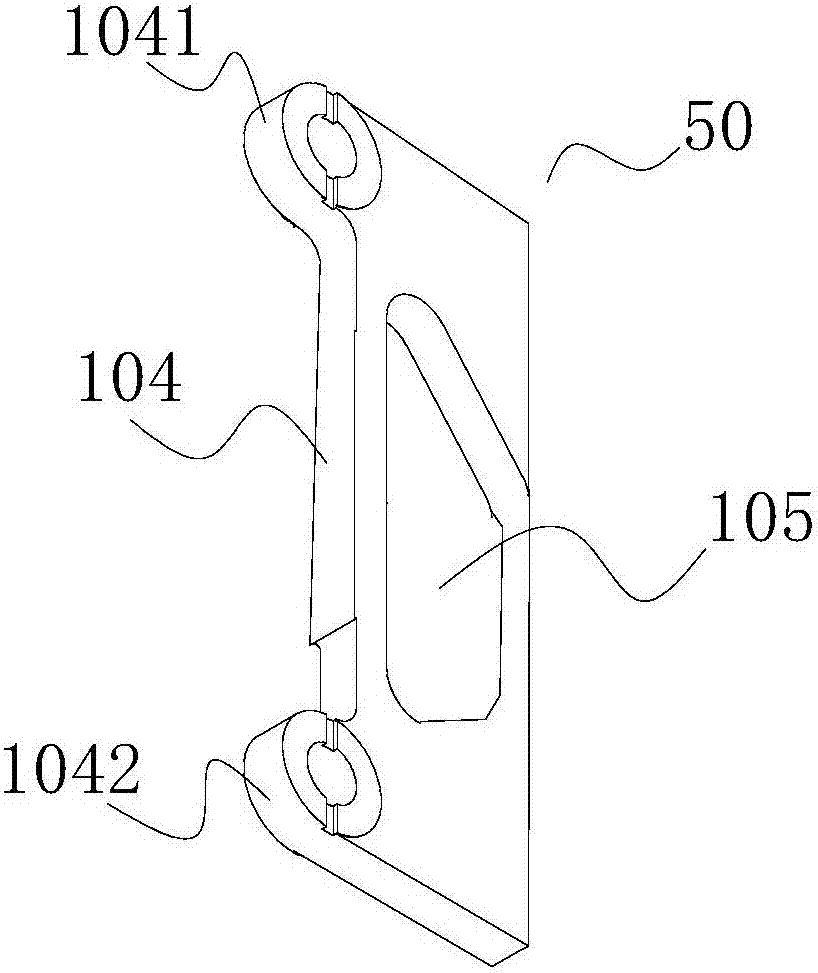

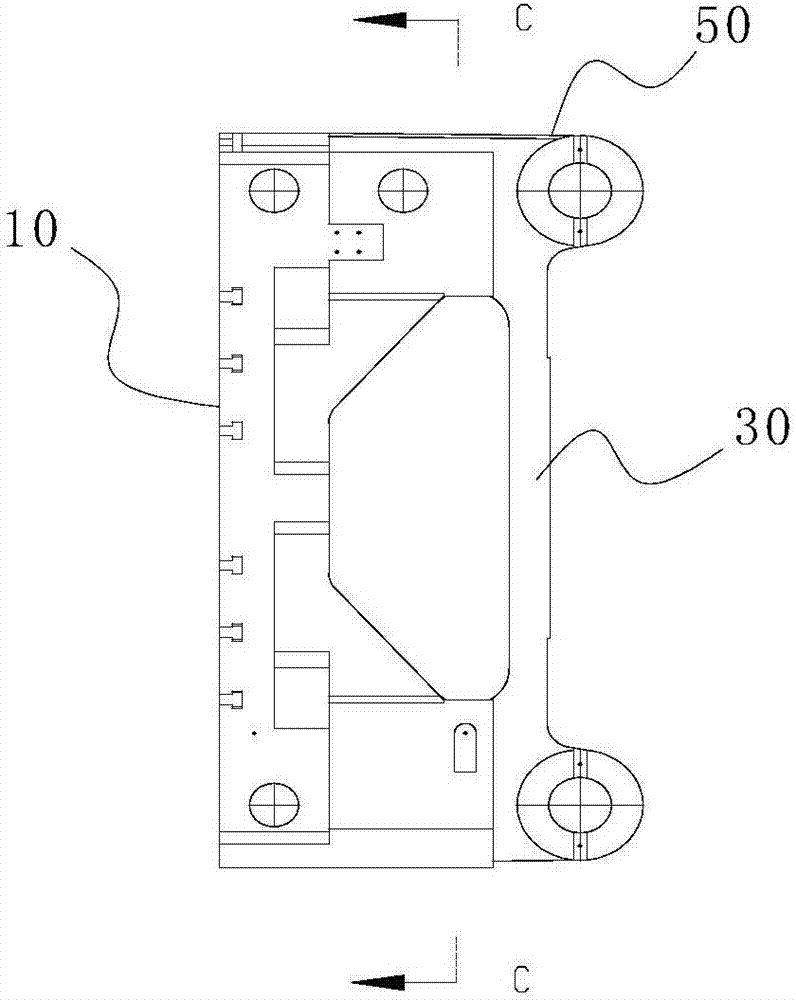

[0025] Figure 1~2 A moving platen of an injection molding machine according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes: a module base 10 , a guide cylinder 21 provided with a guide post hole 20 , a mounting plate 30 of an ejection mechanism, and a machine hinge connection seat system 501 .

[0026] The module base 10 is used as a material for carrying the guide cylinder 21 and the machine-hinged connection seat system 501, and its cross-section is square. On the four corners of the base body 10 , and the machine-hinged connection seat system 501 is arranged between any two adjacent guide cylinders 21 . The machine-hinge joint system 501 is made up of machine-hinge joint 50, and machine-hinge joint 50 is provided with hinge head, and the hinge joint of machine-hinge joint 50 appears in pairs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com