Air entering/draining mechanism for membrane type automobile electric vacuum pump

An electric vacuum pump and diaphragm type technology, which is applied in variable capacity pump components, machines/engines, liquid variable capacity machines, etc., can solve problems such as failure of the brake booster system, impact on service life, and low safety factor, and achieve The effects of balanced operation, dust prevention, and large air extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

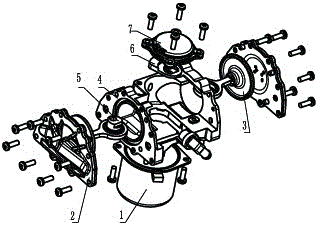

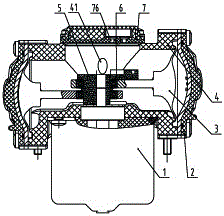

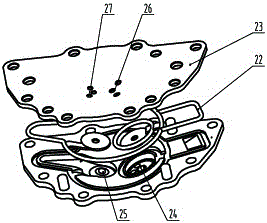

[0021] Combine below Figure 1 to Figure 8 Specific description embodiment:

[0022] Diaphragm electric vacuum pump for automobiles, including motor 1, pump body 4, left and right end cover assemblies 2, piston assemblies 3, mandrel 5 with eccentric holes, balance weight 6 matched with mandrel 5, with check valve and sound absorption The air outlet end cover assembly 7 of the sponge. The inner cavity of the left and right end cap assemblies 2 is divided into an air suction chamber 24 and an exhaust chamber 25, and the pump body 4 is provided with an inlet and exhaust passage 41, which are respectively connected with the air suction chamber 24, the exhaust chamber 25, and the side plate of the left and right end cap assemblies. 23 is provided with two groups of holes 26, 27 respectively communicated with the suction cavity 24 and the exhaust cavity 25, and the one-way valve 22 controls the one-way gas flow direction of the suction and exhaust respectively; The metal insert 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com