Stranding machine for producing power supply cable of hydraulic pump station

A technology for power supply cables and hydraulic pump stations, applied in the field of stranding machines, can solve the problems of easy deformation, relaxation, and the separation of the pay-off frame from the equipment, so as to avoid damage, balance the operation of the stranding machine, and avoid loose strands and twists. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

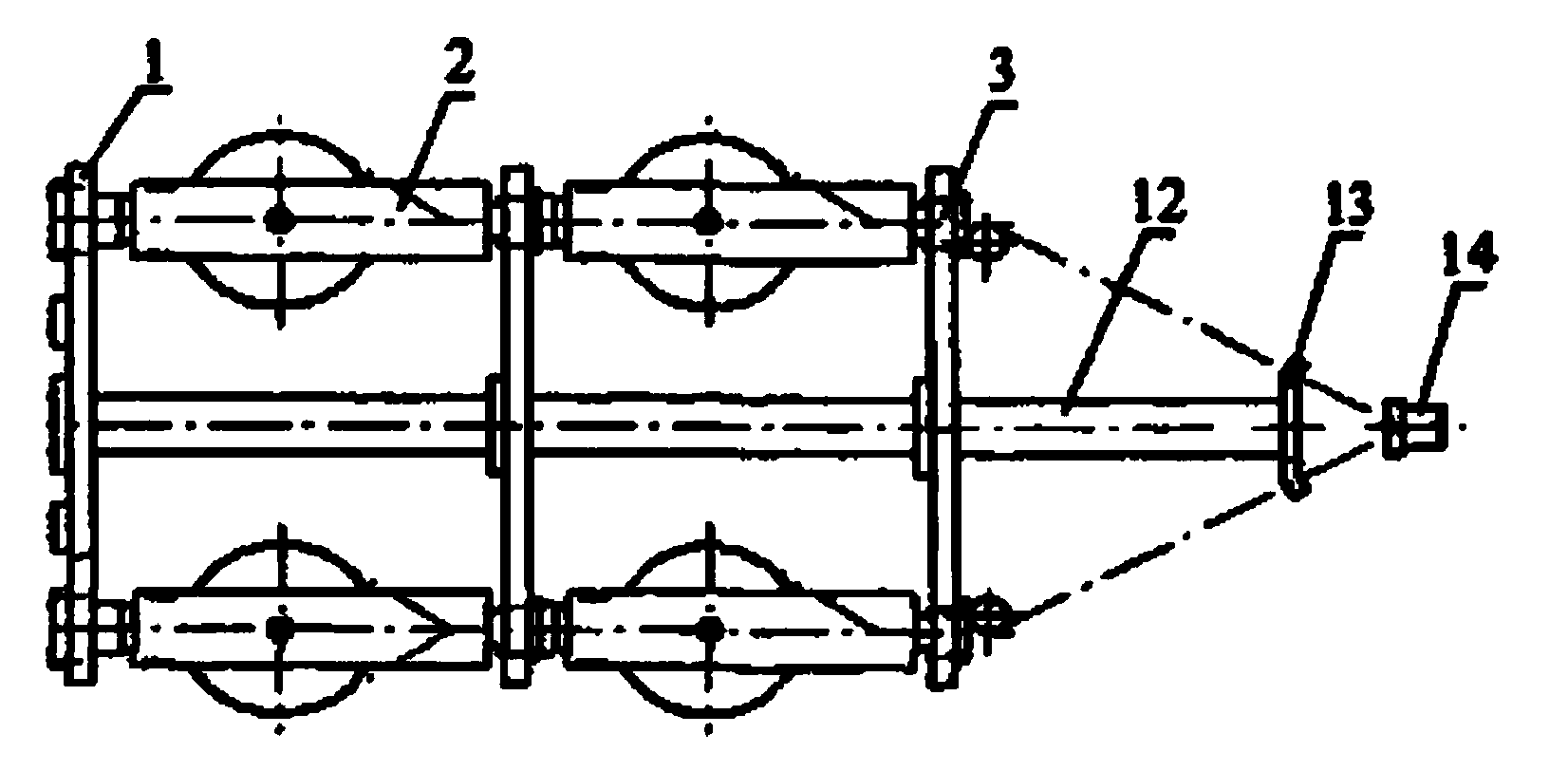

[0021] A stranding machine for producing power supply cables for hydraulic pump stations, used for the stranding cage in the cage stranding machine, which includes a first winch 1, a pay-off frame 2, a second winch 3, a main shaft 12, and a distribution board 13 and the paralleling die 14, the first capstan 1, the second capstan 3, the splitter plate 13 and the paralleling die 14 are sequentially set on the main shaft 12 from left to right.

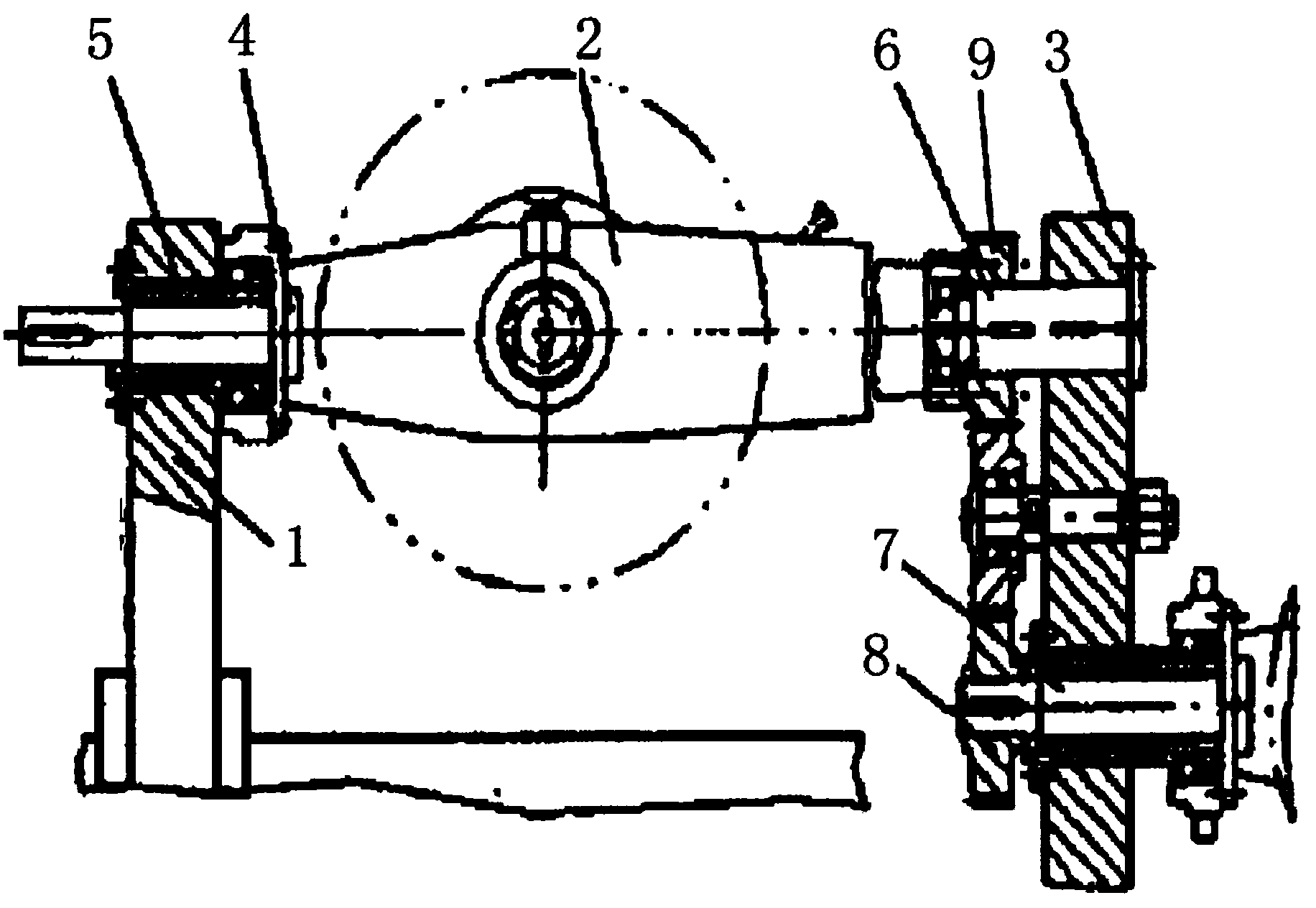

[0022] Two groups of pay-off frames 2 are placed between the first capstan 1 and the second capstan 3 one above the other, and a wire reel and a tension device are placed on each group of pay-off frames 2 . Both ends of each set of pay-off frame 2 are bored with through holes, the left end of the pay-off frame 2 is connected with the first half shaft 4, the first half shaft 4 is fixedly connected with the first centering shaft 5 through the bushing, and the first centering shaft 5 is set on the first half shaft 4 and fixedly connected wit...

Embodiment 2

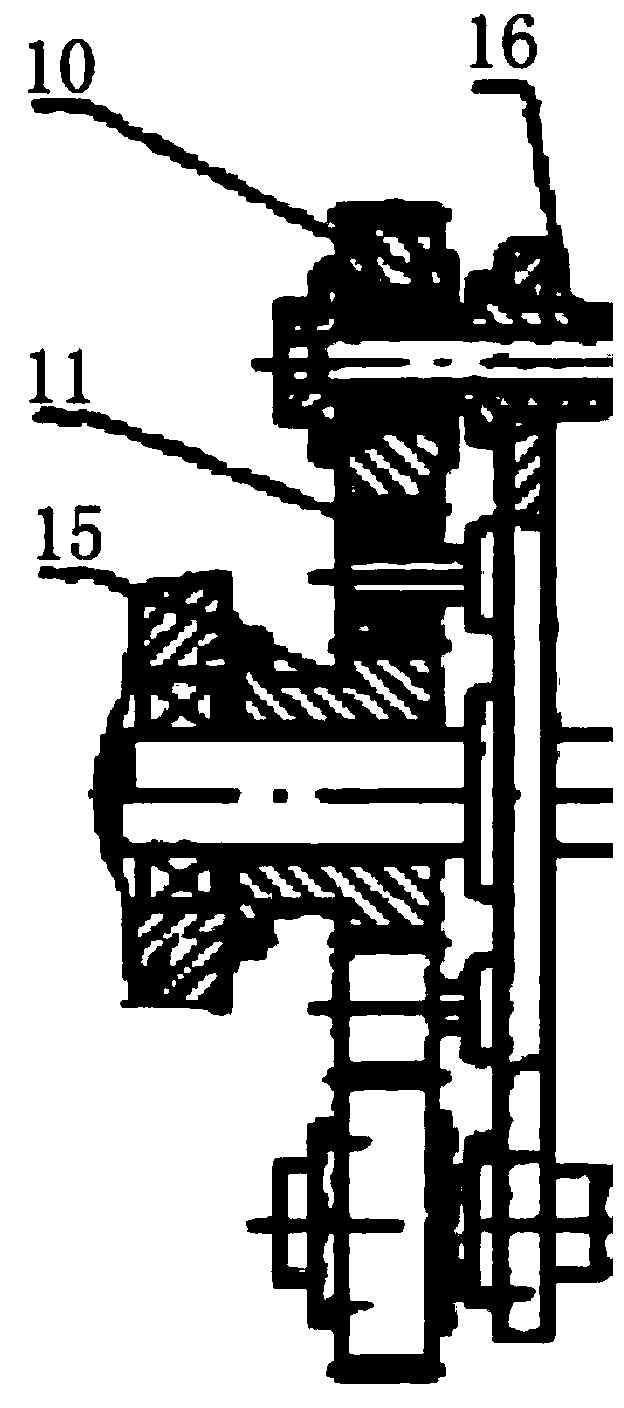

[0025] On the basis of Embodiment 1, the sleeve between the first half shaft 4 and the first centering shaft 5 is an unloading sleeve 16, and the first centering shaft 5 is sleeved in the unloading sleeve 16 in the form of a spline shaft , the first centering shaft 5 with the unloading sleeve 16 is set in the through hole of the first winch 1 as a whole, and the unloading sleeve 16 is connected with the through hole of the first winch 1; There is a spline cover, the spline cover at the right end of the first centering shaft 5 is fixedly connected in the through hole at the left end of the pay-off frame by means of screw connection, the spline cover at the left end of the first centering shaft 5 is connected to the twist-back gear 10 Fixed connection. Therefore, the gear drives the pay-off frame to rotate through the spline cover and the spline shaft.

[0026] An unloading sleeve is also arranged between the first centering shaft and the first capstan. The huge inertial centri...

Embodiment 3

[0028] The second centering shaft 6 is a flange shaft, and the end face of the second centering shaft 6 is fastened on the second capstan 3 with 6 M12 screws. The second centering shaft 6 is equipped with a self-aligning bearing, and the right end of the pay-off frame 2 is The through hole is set on the self-aligning bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com