Roller blind type phosphogypsum drying conveyer belt

A conveyor belt and roller shutter technology, applied in the field of roller shutter phosphogypsum drying conveyor belt, can solve the problems of large floor area, expensive phosphogypsum drying equipment, large land occupation, etc., and achieve fast running speed, Easy maintenance and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

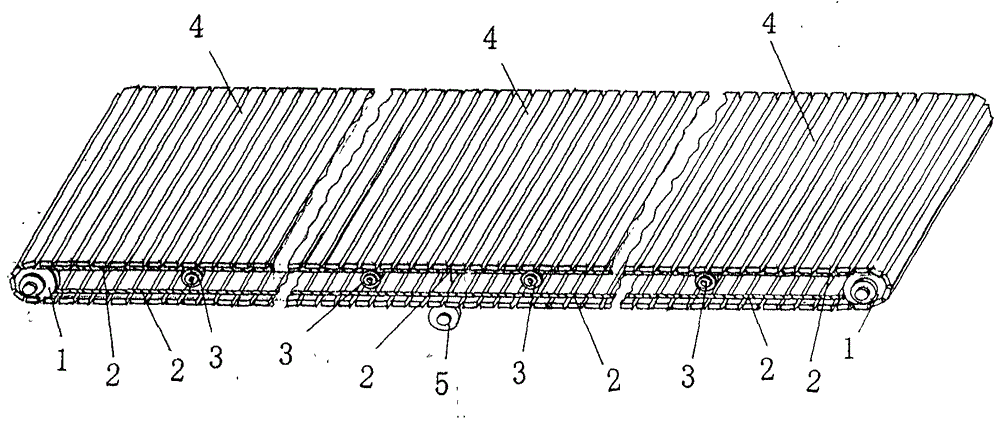

[0009] figure 1 Shown: The conveyor belt used for conveying materials has a driving sheave 1 at both ends of the two sides, and a circularly rotating steel wire rope 2 is wound between the driving sheave 1 at both ends of the two sides, and densely clothed on the wire rope 2. There are a plurality of slats 4, and several support rollers 3 with driving discs are distributed in the steel wire ropes 2 on both sides, and the roller-blind conveyor belt formed by this is equipped with a tension pulley 5 as a whole.

[0010] The driving sheave 1 and several support pulleys 3 are all sheaves that can be inserted into the steel wire rope 2 for cyclic operation, and the support pulley 3 can be used to fix the transmission disc on the outside, so that it can be connected to the power drive, so that the overall transmission power is more stable. for strong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com