Chamfering and cutting flame trolley

A flame and trolley technology, which is applied in the field of chamfering and cutting flame trolleys, can solve problems such as difficulty in chamfering cutting of thin plates, and achieve the effect of easy promotion and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

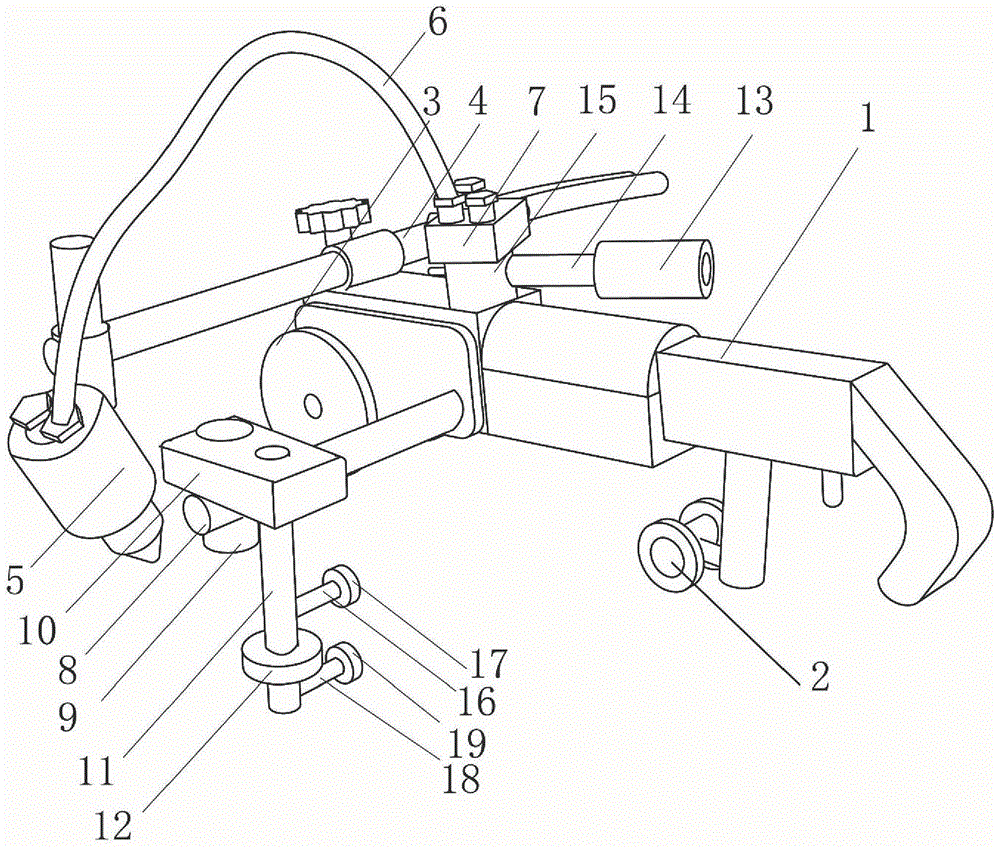

[0022] Such as figure 1 As shown, the chamfering cutting flame trolley includes flame gas cutting machine main body 1, universal wheel 2, road wheel 3, tail adjustment rod 4 and flame nozzle 5, universal wheel 2 and road wheel 3 are respectively installed on the flame gas cutting machine body 1, the front and the rear of the tail adjusting rod 4 are connected to the main body of the flame gas cutting machine 1 at one end, and the flame nozzle 5 is installed at the other end. A rotating part 15 is arranged under the air pump 7, and one end of the counterweight slide bar 14 is fixedly connected with the rotating part 15, and the other end is provided with a counterweight part 13. The side part of the main body 1 of the flame cutting machine is fixedly connected with one end of the side connecting rod 8, and the other end of the side connecting rod 8 is connected to the guide clamping part 10 through the side lifting rod 9, and the guide clamping part 10 is also provided with a g...

Embodiment 2

[0025] The difference from Example 1 is that a 6mm thick curved steel plate edge is used for 30-degree chamfering. The experimental steel plate edge has an arc length of 12 meters, a radius of 8 meters, and an arc of 70 degrees. The chamfering and cutting work is completed in about 7 minutes. .

Embodiment 3

[0027] The difference from Example 1 is that a 12mm thick curved steel plate edge is used for 30-degree chamfering. The experimental steel plate edge has an arc length of 11 meters, a radius of 8 meters, and an arc of 80 degrees. The chamfering and cutting work is completed in about 6 minutes. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com