Bilateral special-shaped hole punching machine

A punching machine, bilateral technology, applied in the direction of perforating tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, holes that can only be punched on one side, easy deformation and swelling, etc., to improve work efficiency and ensure product quality Quality, effect against deformation and bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

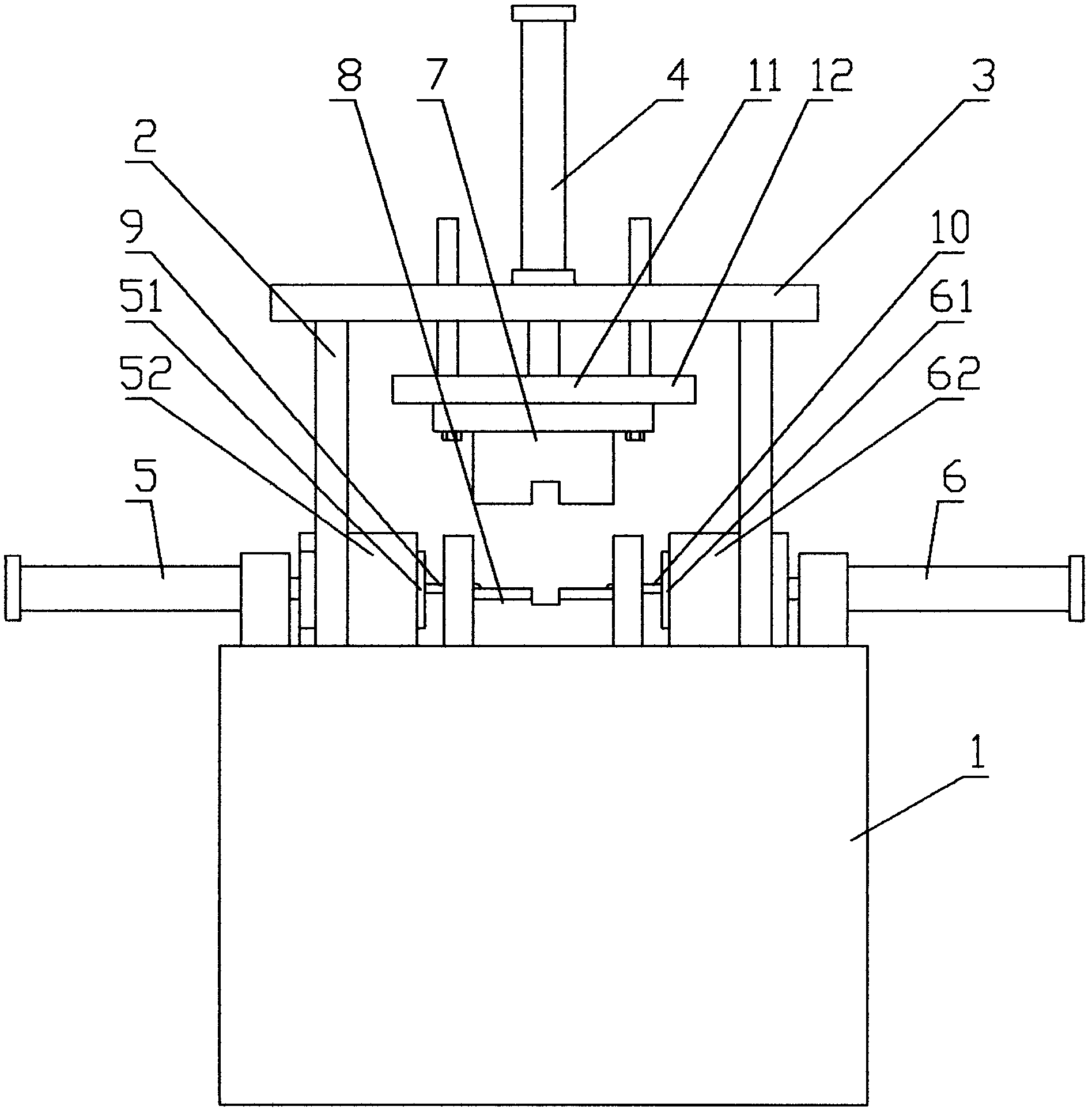

[0025] Example: see Figures 1 to 5 As shown, the double-sided different-diameter punching machine includes a workbench 1, four columns 2 are fixed on the workbench 1, a top plate 3 is fixed on the column 2, an upper mold drive cylinder 4 is fixed on the top plate 3, and the workbench 1 is fixed. There are a left punching cylinder 5 and a right punching cylinder 6, and the left punching cylinder 5 and the right punching cylinder 6 are relatively arranged on the workbench 1;

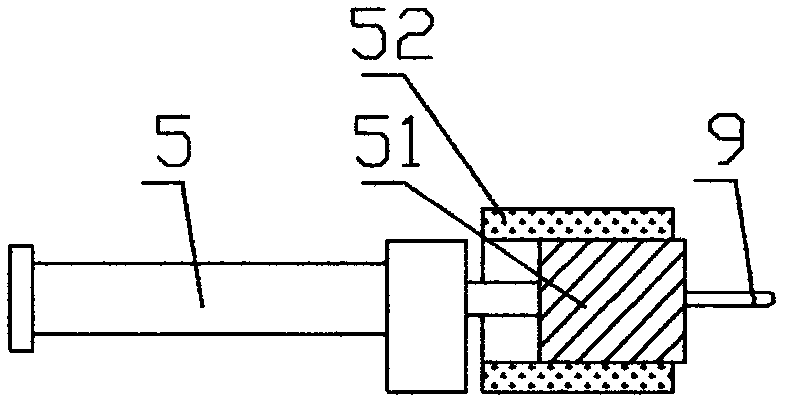

[0026] The piston rod of the left punching cylinder 5 is fixed with a left punching block 51, the left punching block 51 is inserted and sleeved in the left guide block 52, and the left guide block 52 is fixed on the workbench 1 in front of the piston rod of the left punching oil cylinder 5 ;

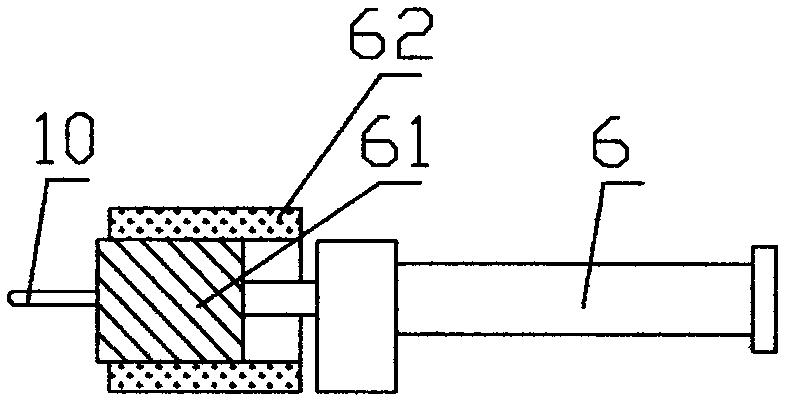

[0027] The piston rod of the right punching cylinder 6 is fixed with a right punching block 61, the right punching block 61 is inserted into the right guide block 62, and the right guide block 62 is fixed on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com