Chain transmission tension regulating mechanism of framing shaping machine

A tenter setting machine and tension adjustment technology, applied in conveyors, fabric elongation, textiles and papermaking, etc., can solve problems such as troublesome adjustment, unstable tension, and unstable chain drive, and achieve consistent results and chain drive. The effect of running balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

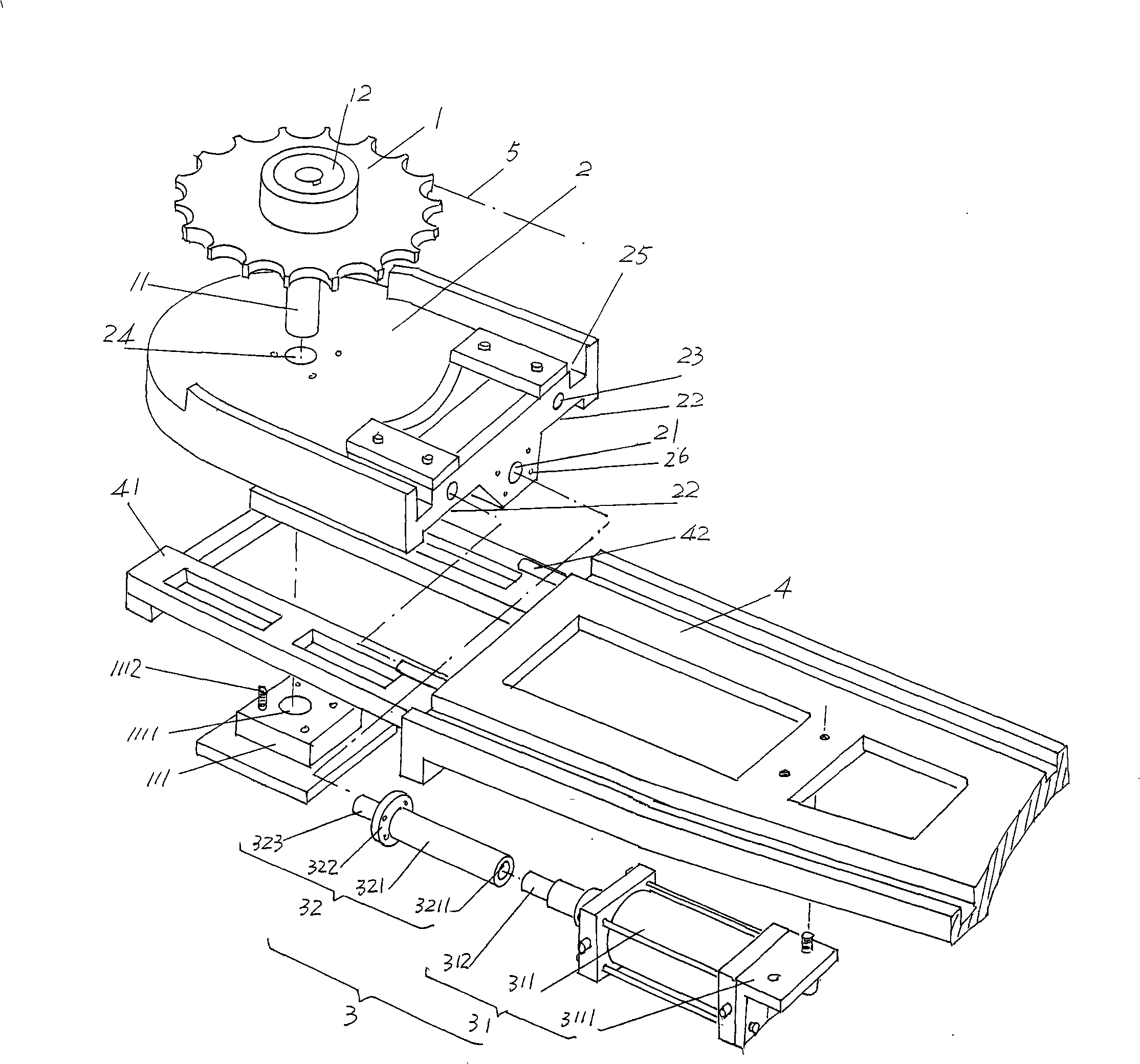

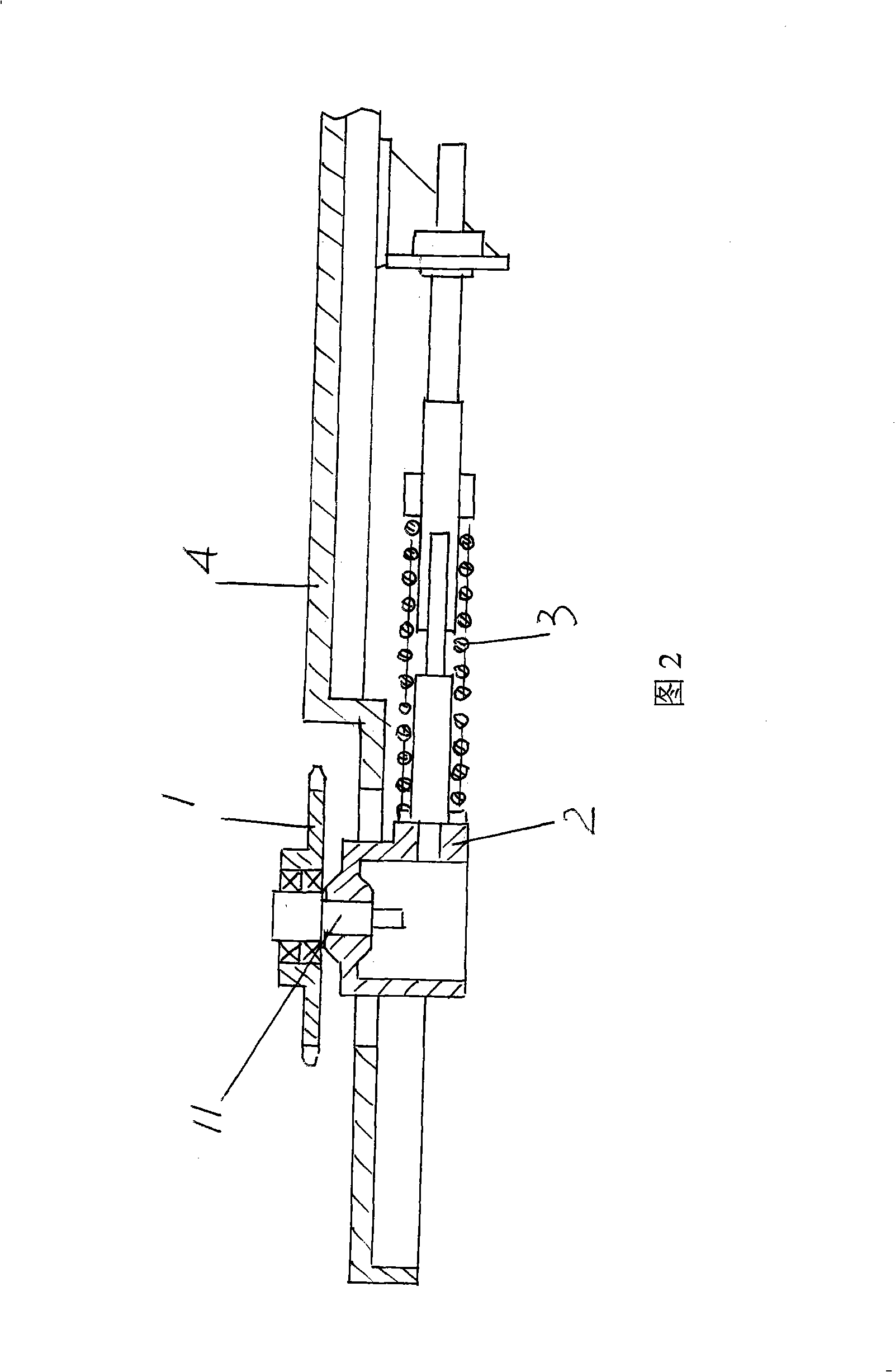

[0019] please see figure 1 , according to the well-known common sense in the industry, there are a pair of cloth feeding tracks of the head 4 of the stenter setting machine facing each other, so the chain transmission tension adjustment mechanism of the present invention also has a pair correspondingly, because the structure of a pair of chain transmission tension adjustment mechanisms , installation method and working principle are all the same, so the applicant's description below is only for one of them.

[0020] A pair of slide seat guide rails 41 are processed at one end of the head 4 on one side of the stenter setting machine, and a pair of guide rods 42 are extended on the end face corresponding to the tail end face of the slide seat 2 . The sprocket 1 is pivoted on the upper end of the central shaft 11 through the bearing 12, and the lower end of the central shaft 11 passes through the central shaft hole 24 preset on the sliding seat 2 and supports the preset central s...

Embodiment 2

[0023] The oil cylinder is selected as the action cylinder 31, and the rest are the same as those described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com