Control method for preventing parallel running fans from tacking phenomenon

A control method and fan technology, applied in pump control, separation method, machine/engine, etc., can solve problems that endanger the operation safety of boiler units, endanger the safety of fan equipment, and the life of fan blades, and achieve a smooth switching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

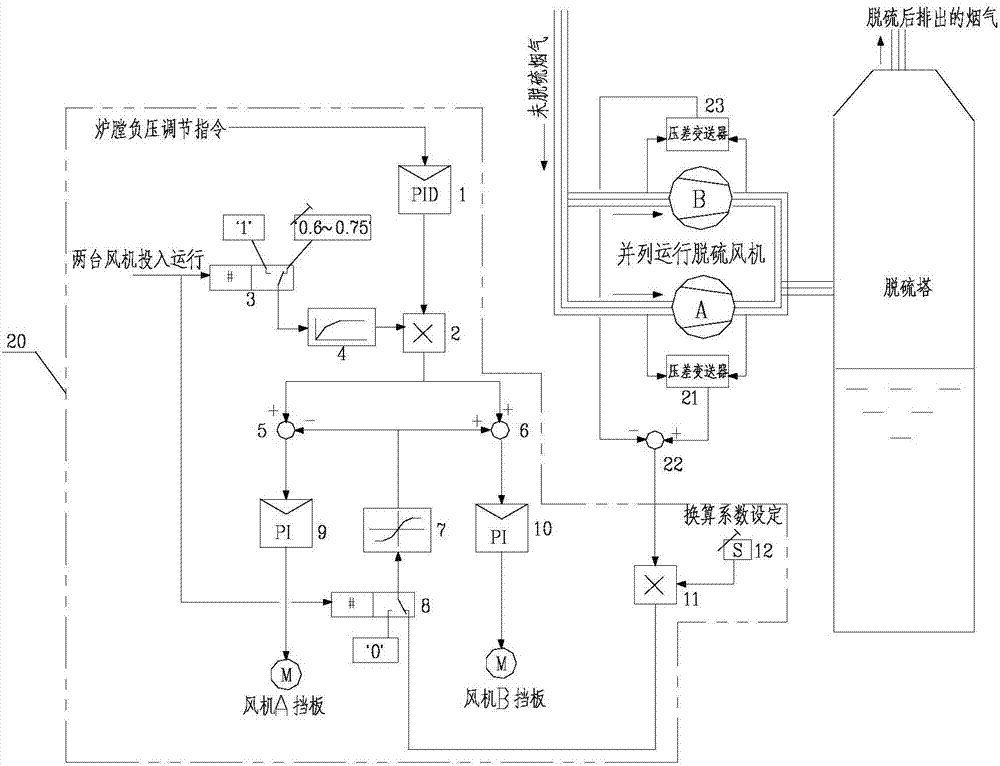

[0040] Example 1 - Parallel operation of two fans

[0041] When two fans, fan A and fan B, are running at the same time, the positions of gain switcher 3 and switcher 8 are as follows: figure 1 As shown, that is, the gain signal value output by the gain switcher 3 is adjustable within the range of 0.6 to 0.75, the preferred gain signal value output by the gain switcher 3 is 0.7, the output of the switcher 8 is the output of the second multiplier 11, and the output of the second multiplier 11 is The output value of the double multiplier 11 represents the difference between the output signals of the two fan outlet and inlet differential pressure transmitters 21 and 23 and is corrected by the conversion coefficient output by the coefficient setter 12 to the corresponding baffle opening correction value. The output values of the gain switcher 3 and the switcher 8 enter the speed limiter 4 and the two-way speed limiter 7 respectively to ensure the smooth progress of the switching...

Embodiment 2

[0045] Example 2 - Operating conditions of a single fan

[0046] When a single fan in fan A or fan B is running, the gain switcher 3 and switcher 8 switch to the same figure 1 The opposite position, that is, the gain signal value of the gain switcher 3 output is 1, the output of the switcher 8 is 0, the gain signal value of the speed limiter 4 output after entering the steady state is 1, and the output value of the two-way speed limiter 7 is 0. At this time, the furnace negative pressure adjustment instruction is calculated by the main regulator 1 and then output the adjustment signal value to the first multiplier 2, and multiplied by the gain signal value output by the speed limiter 4 in the first multiplier 2, and the result remains unchanged, the gain adjustment value output by the first multiplier 2 is simultaneously sent to the adder A 5 and the adder B 6 . Since the two-way speed limiter 7 does not receive the output value of the second multiplier 11 at this moment, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com