Multipurpose pumping-exhaust flue dust processor of serially-connected gas-washing pools

A gas scrubbing tank, multi-purpose technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as insufficient dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

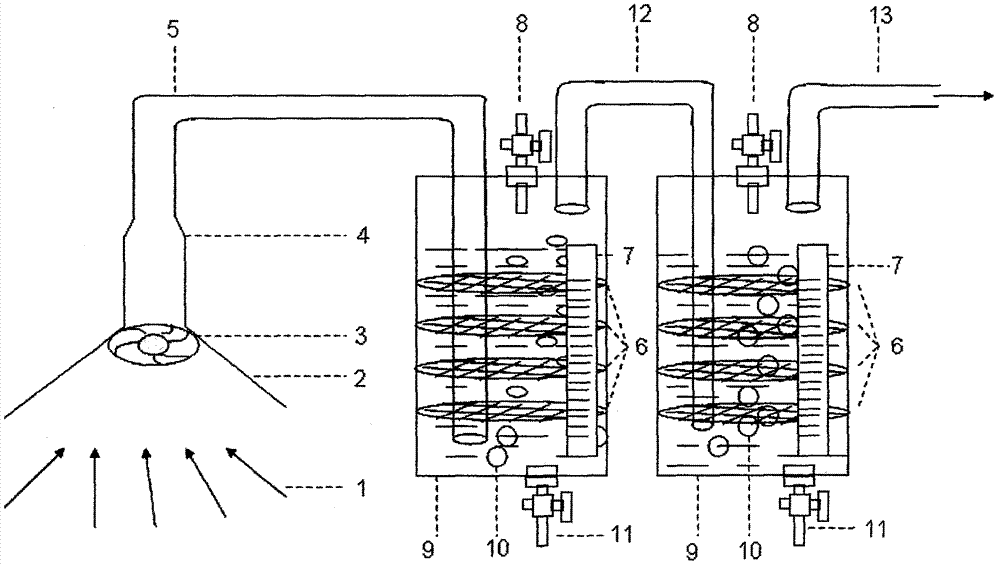

[0006] The smoke (1) is blown into the scrubber (9) by the exhaust fan (3) in the dust collecting hood (2) through the pipeline. Under the suction of the vacuum pump (13), the smoke and dust are discharged with large bubbles from the bottom of the scrubber. During the process of floating, the bubbles encounter the bubble dispersing screen (6) and are dispersed into tiny bubbles, thereby greatly increasing the contact area with the solution in the scrubber. The scrubbing tanks connected in series are filled with scrubbing solution, especially surfactant solution such as soap, because of the characteristics of the gas, which can greatly increase the dissolution of harmful gas and the wetting and suspension of dust carried, so that it can be removed. The exhaust gas is sucked away by the vacuum pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com