Polyurethane foaming bag blocked gas drainage hole

A technology of gas drainage and polyurethane, which is applied in the direction of gas discharge, sealing/isolation, safety devices, etc., to achieve the effect of not consuming energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

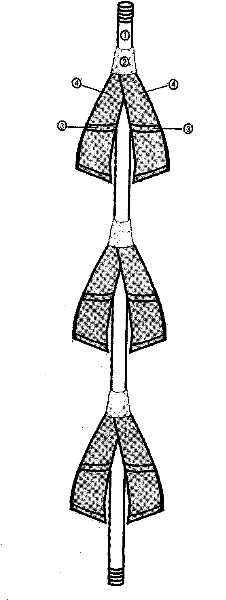

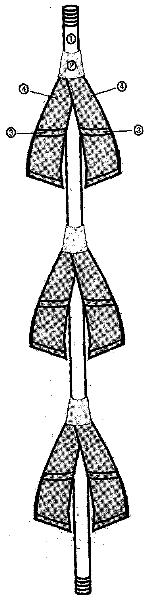

[0014] exist figure 1 , erect the gas drainage pipe ① upwards, and use adhesive tape to vertically wrap the polyurethane foam bag on the gas drainage pipe ①. As shown in the wrapping tape ②, the tape can be wrapped and tied to the polyurethane foam bag ④ 2-4cm from the top. The binding should be relatively firm, not only to ensure that the foam bag does not fall off and not in place when entering the gas drainage hole, but also to control the self-explosive discharge direction.

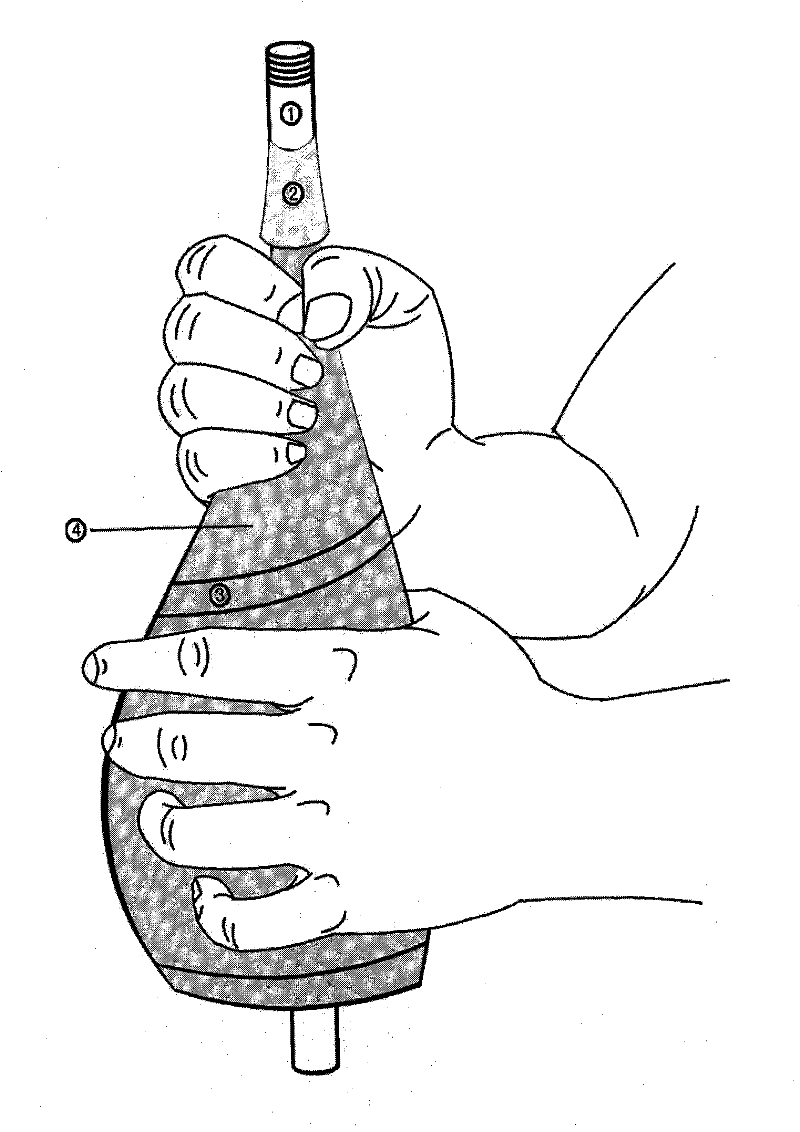

[0015] exist figure 2 In the process, hold the upper and lower parts of the foam bag ④ with both hands, so that the middle seal ③ of the foam bag ④ is between the two hands. The middle seal ③ can be flushed open by holding both hands at the same time, so the two types of materials in the foam bag ④ are mixed together from the separated state. Then, the two hands are respectively loosened and squeezed for about 30 times, and the materials in the foam bag ④ are separated. The two materials have been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com