Method and device for pre-pumping coal body gas by concussion fracture of high-pressure gas

A technology of impact rupture and high-pressure gas, which is used in gas discharge, safety devices, mining equipment, etc., can solve the problem of the system without a walking mechanism, and achieve the effect of improving the gas drainage effect, enhancing the permeability, and improving the rupture effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

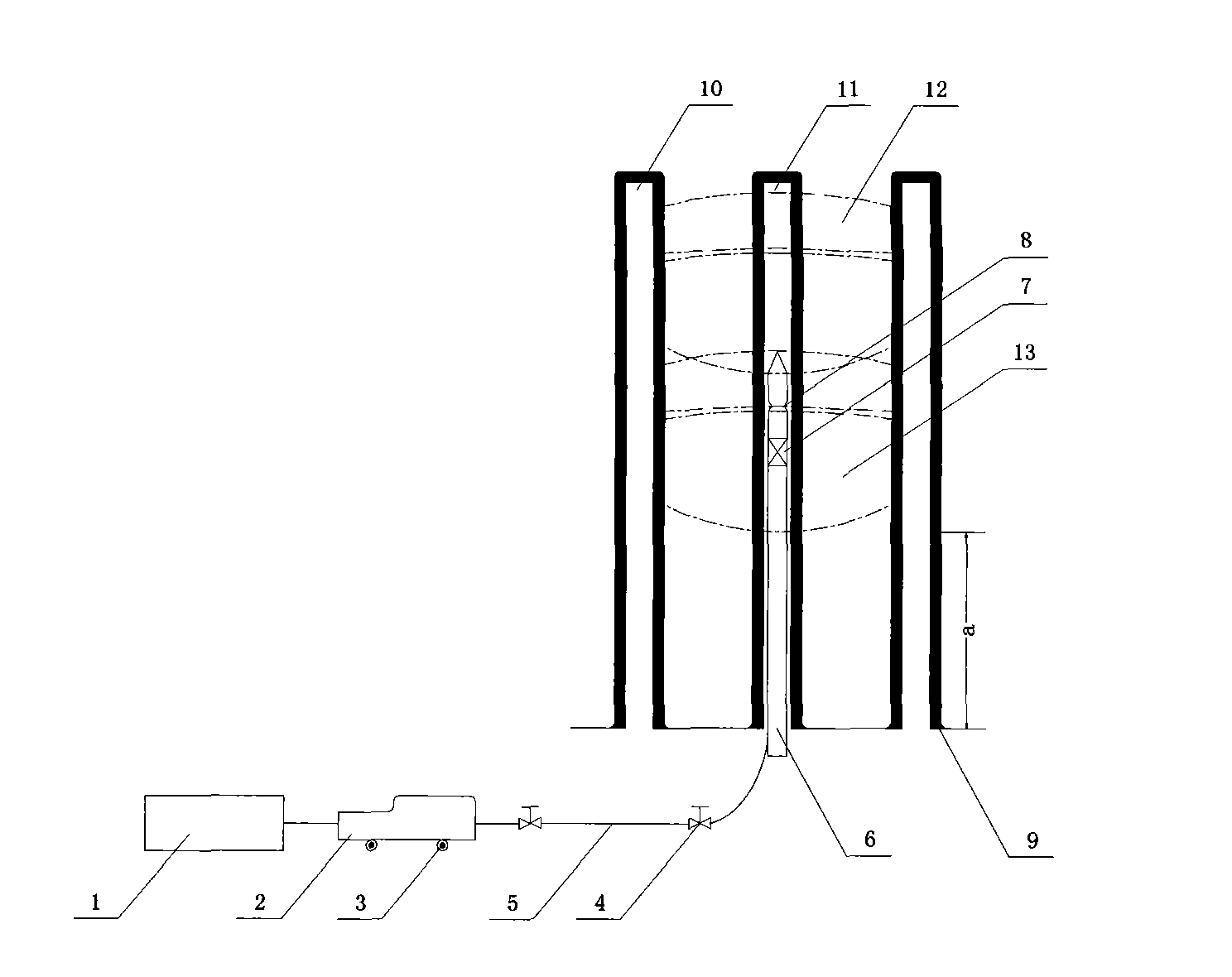

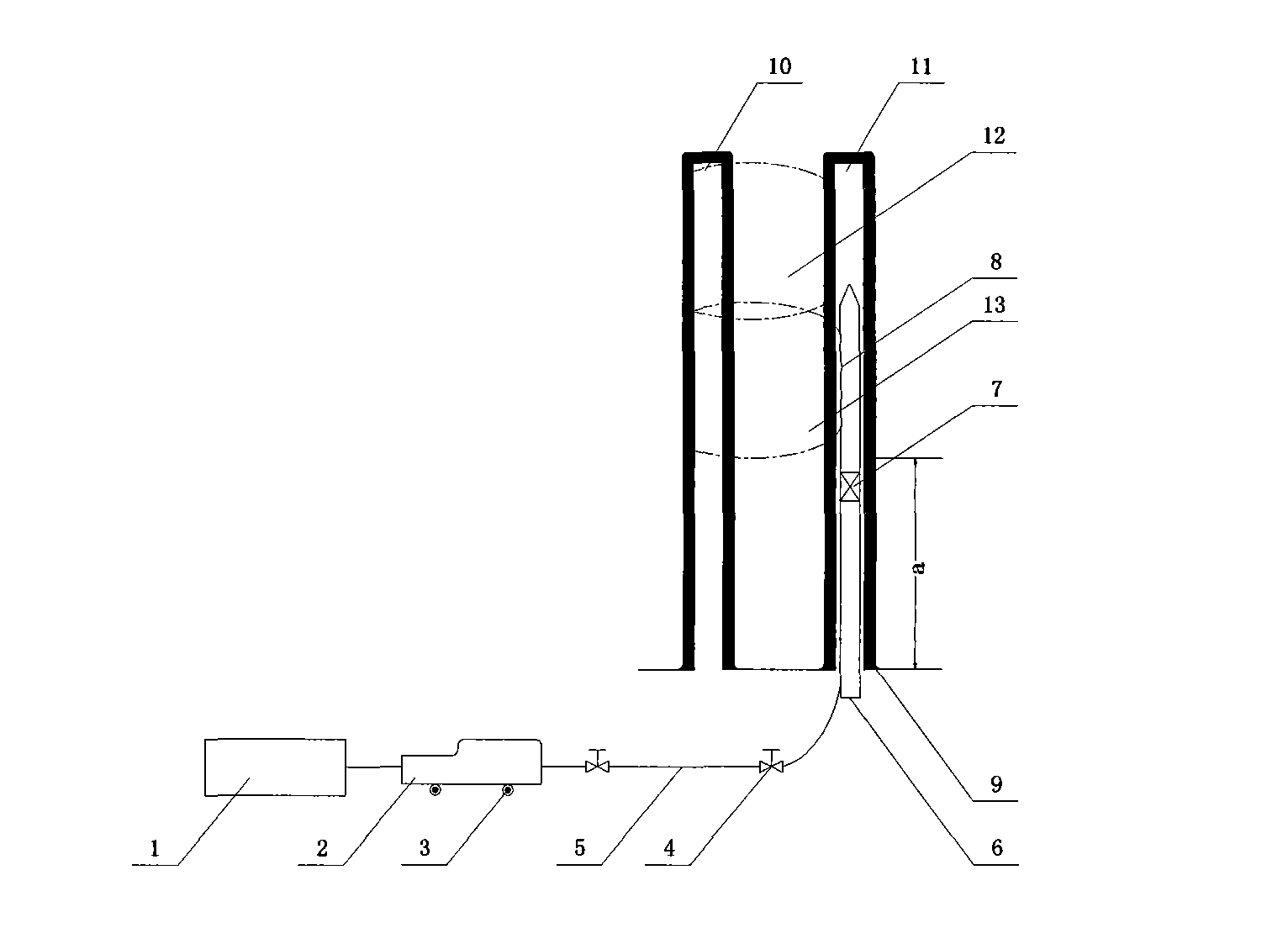

[0016] Figure number

[0017] In the figure 1. Electric control system, 2. High-pressure air compressor, 3. High-pressure air compressor travel shaft wheel, 4. High-pressure control valve, 5. High-pressure pipeline, 6. High-pressure accumulator, 7. High-voltage trigger, 8. High-pressure gas impact nozzle, 9. Coal wall, 10. Control drilling, 11. Impact fracture drilling, 12. Impact fracture impact range of the first stage, 13. Impact fracture impact range of the second stage, a. Retain the coal wall thickness.

[0018] figure 1 . In the first embodiment of the present invention shown, a high-pressure gas impact fracture coal gas pre-extraction equipment includes an electric control system 1 electrically connected to a high-pressure air compressor 2, and a high-pressure control valve connected to the high-pressure air compressor 2 The high-pressure pipeline 5 of 4 is connected with a high-pressure accumulator 6 with a high-pressure trigger 7 and a high-pressure gas impact nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com