Pipeline transportation vacuum forming method and device adopting piston-type vehicle push and press air exhaust

A piston type and pipeline technology, applied in the direction of roads, tracks, tunnel systems, etc., can solve the problem of low exhaust efficiency, reduce costs and investment, improve economic benefits, and improve overall economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following examples.

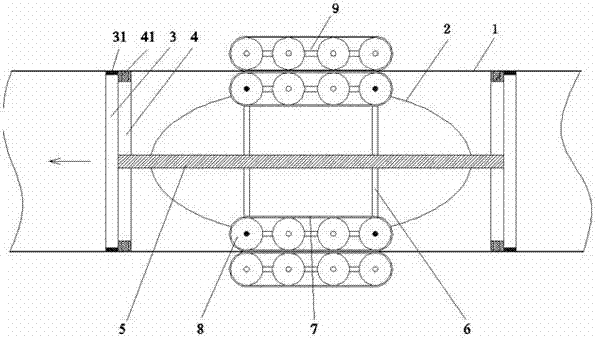

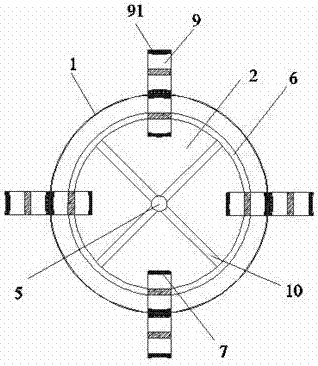

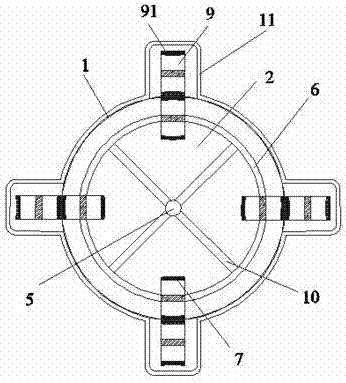

[0035] like figure 1 , figure 2 As shown, the inner wall of the pipe must be smooth, the pipe wall is thin, 1~8mm, and it is made of non-magnetic material. The cross-section of the pipe is a regular circle, and it can also be an ellipse or other shapes without edges and corners. The longitudinal direction of the pipe must be continuous and smooth to ensure that the piston vehicle body can move forward smoothly without air leakage to the rear.

[0036]Piston-type vehicles are provided with pistons at the front end and rear end, and the piston ring a around the piston is made of rubber material, or other materials with elasticity and good sealing effect. Piston ring a also can adopt as the magnetic sealing strip that common refrigerator door seals. The piston ring a is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com