Arrangement method for gas drainage drill sites of highly-gassy fully-mechanized top-coal caving surface

A technology for fully mechanized caving face and gas drainage, which is applied in gas discharge, safety devices, directional drilling, etc., can solve the problems of increasing the air volume of the working face and the gas concentration exceeding the limit, and achieves good drainage effect.

Inactive Publication Date: 2011-08-24

BIN COUNTY WATER CURTAIN CAVE COAL

View PDF6 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After the gas drainage, the gas concentration in the return air corner has remained high during the push-out process of the fully-mechanized caving face. The upper and lower corners are built with gangue bags to block, and the air volume of the working face is increased. The gas concentration often exceeds the limit when the top coal is caving and the working face is pressed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] The specific implementation of the present invention is as described in the summary of the invention, and those skilled in the art can fully implement it according to the description of the specification, and will not be described in detail here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

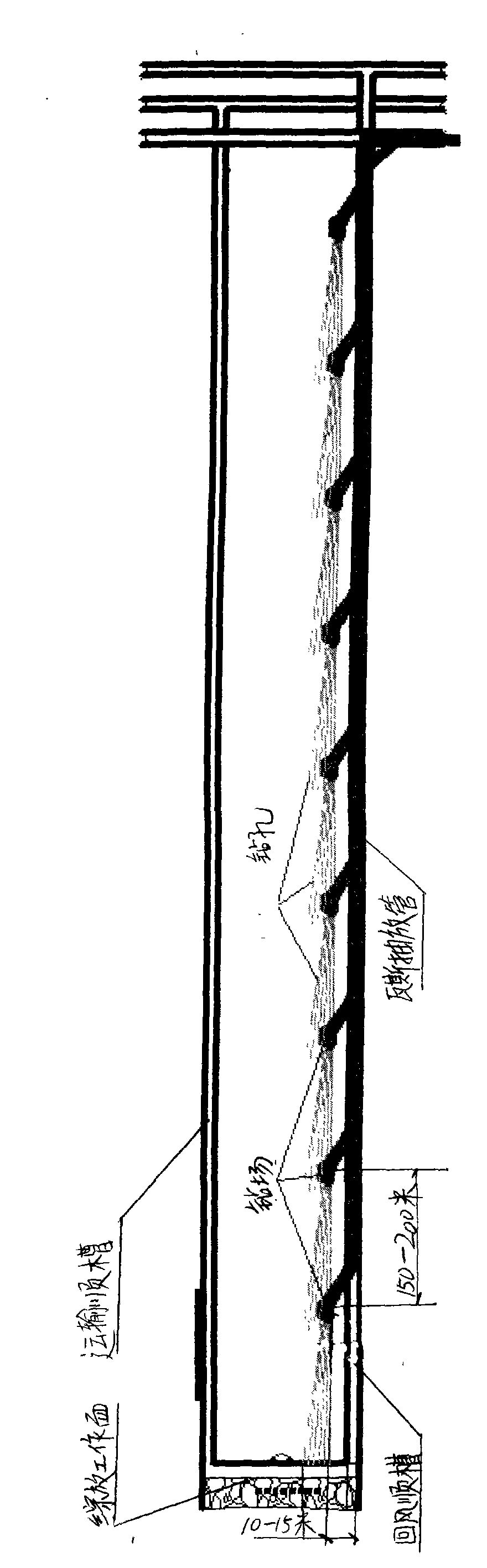

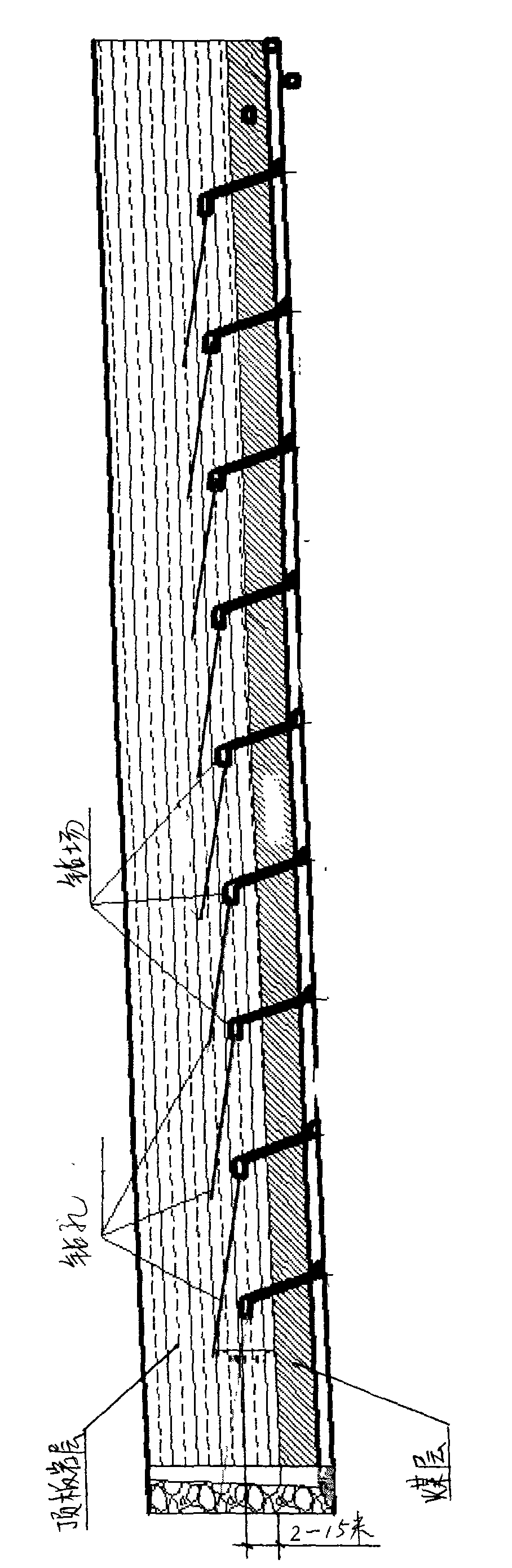

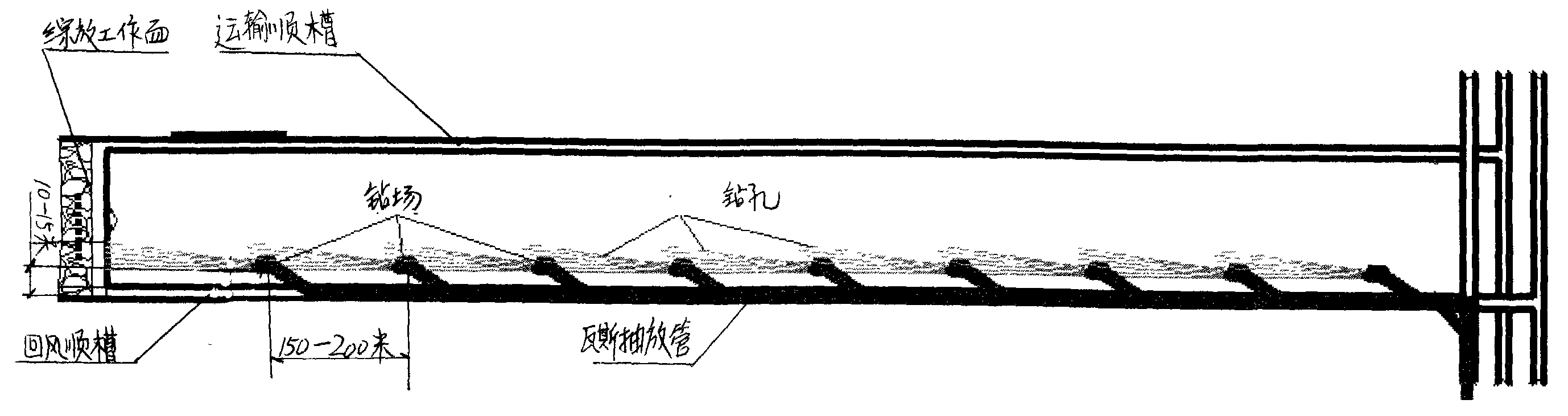

The invention discloses an arrangement method for gas drainage drill sites of a highly-gassy fully-mechanized top-coal caving surface, which comprises the following steps of: constructing the drill sites above a roof of a coal seam of an air return roadway of the fully-mechanized top-coal caving surface; constructing six drill holes in the drill sites, and drilling the drill holes by using a centralizer according to the design direction, wherein the coverage range of the drainage drill hole in the latter drill site on the previous drill site is more than or equal to 50 meters; and after constructing the drill holes, pre-burying an end pipe by using a polyurethane material, and arranging a gas drainage pipe in the end pipe to drain gas. The arrangement method has the advantage that after top coal of the caving surface is discharged, the effused gas rises to a fissure zone and enters the drill holes constructed to the inside of the fissure zone, and is drained by the gas drainage pipe without entering air turn corners again, so the high-position drill holes plays the role of blocking and intercepting the gas.

Description

technical field [0001] The invention relates to a coal mine gas drainage technology, which is suitable for controlling the corner gas in the return air corner of the top coal caving face in high gas fully mechanized mining, can reduce the corner gas to below the safety value of the "Coal Mine Safety Regulations", and can provide gas pumping There is sufficient and stable concentration in the discharge pipeline for the gas unit to generate electricity. Background technique [0002] Article 133 of the "Coal Mine Safety Regulations" stipulates that as long as gas is found in one coal (rock) layer in a mine, the mine is a gas mine. Gas mines must be managed according to mine gas grades, high gas mines: the relative gas emission of mines is greater than 10m 3 / t or the absolute gas emission of the mine is greater than 40m 3 / min; Article 134 of the "Coal Mine Safety Regulations" In low-gas mines, the relative gas emission is greater than 10m 3 / t or individual areas (mining ar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21F7/00E21B7/04

Inventor 刘永李琳李乃禄陈成果

Owner BIN COUNTY WATER CURTAIN CAVE COAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com