Low permeability coal seam electricity explosion vibration and microwave assisting liquid nitrogen freeze-thawing permeability increasing device and method

A microwave-assisted, electric detonation technology, applied in safety devices, earth-moving drilling, gas discharge, etc., can solve problems such as inability to meet mine production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

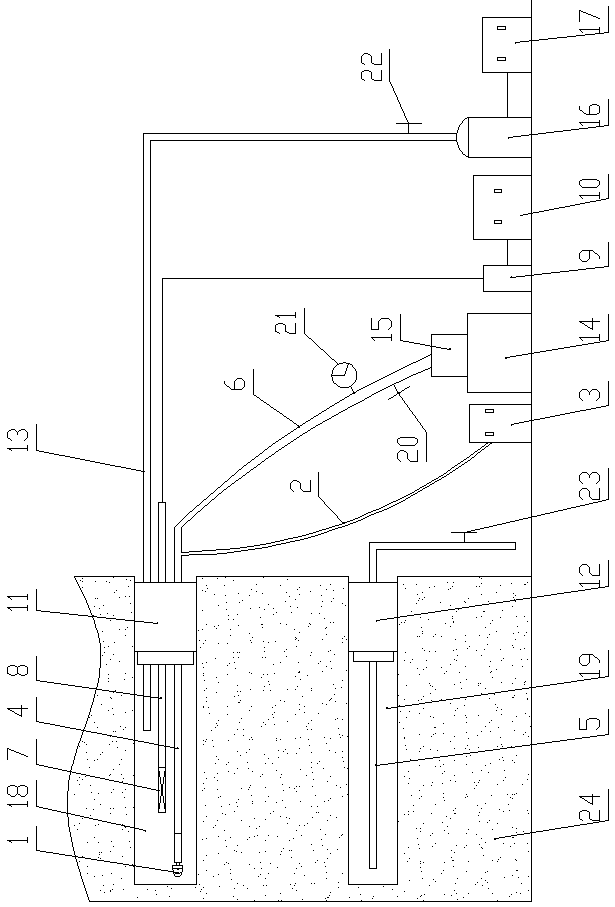

[0024] like figure 1 As shown, the low-permeability coal seam electric detonation and microwave-assisted liquid nitrogen freeze-thaw anti-permeability device of the present invention includes a pulse discharge reactor 1, a cable 2, a high-voltage pulse generator 3, a fracturing tube 4, a drainage tube 5, a high-voltage Rubber hose 6, microwave transmitter 7, coaxial waveguide 8, microwave converter 9, microwave generator 10, first hole sealing device 11, second hole sealing device 12, nitrogen injection pipe 13, water tank 14, high pressure water pump 15, liquid Nitrogen pump 16 and liquid nitrogen tank 17;

[0025] The fracturing pipe 4, cable 2, coaxial waveguide 8 and nitrogen injection pipe 13 extend into the freeze-thaw borehole 18, the drainage pipe 5 extends into the drainage borehole 19, and the freeze-thaw borehole 18 and the drainage borehole The holes 19 are parallel and 3-8m apart, and the first hole sealer 11 is arranged at the orifice of the freeze-thaw borehole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com