Sealing ring

A sealing ring and sealing lip technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as oil leakage, and achieve the effect of enhancing pump return and reducing fluid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

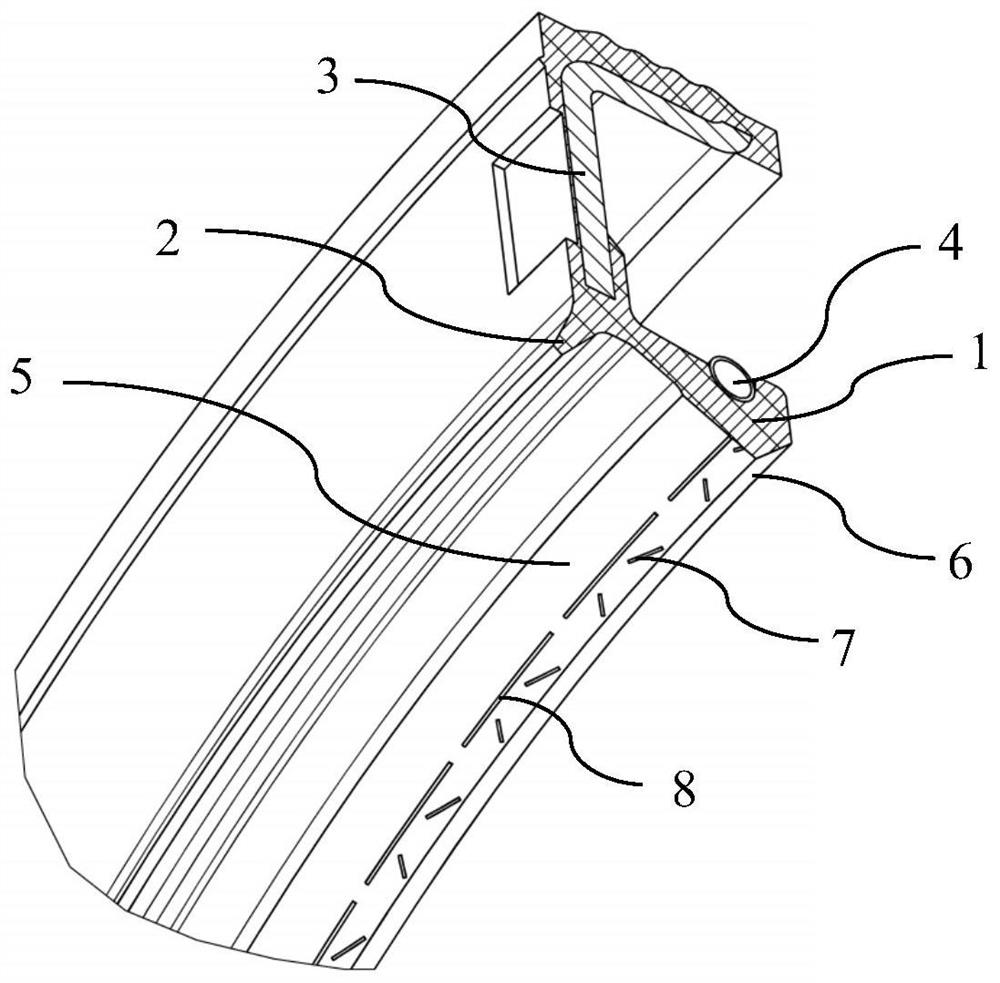

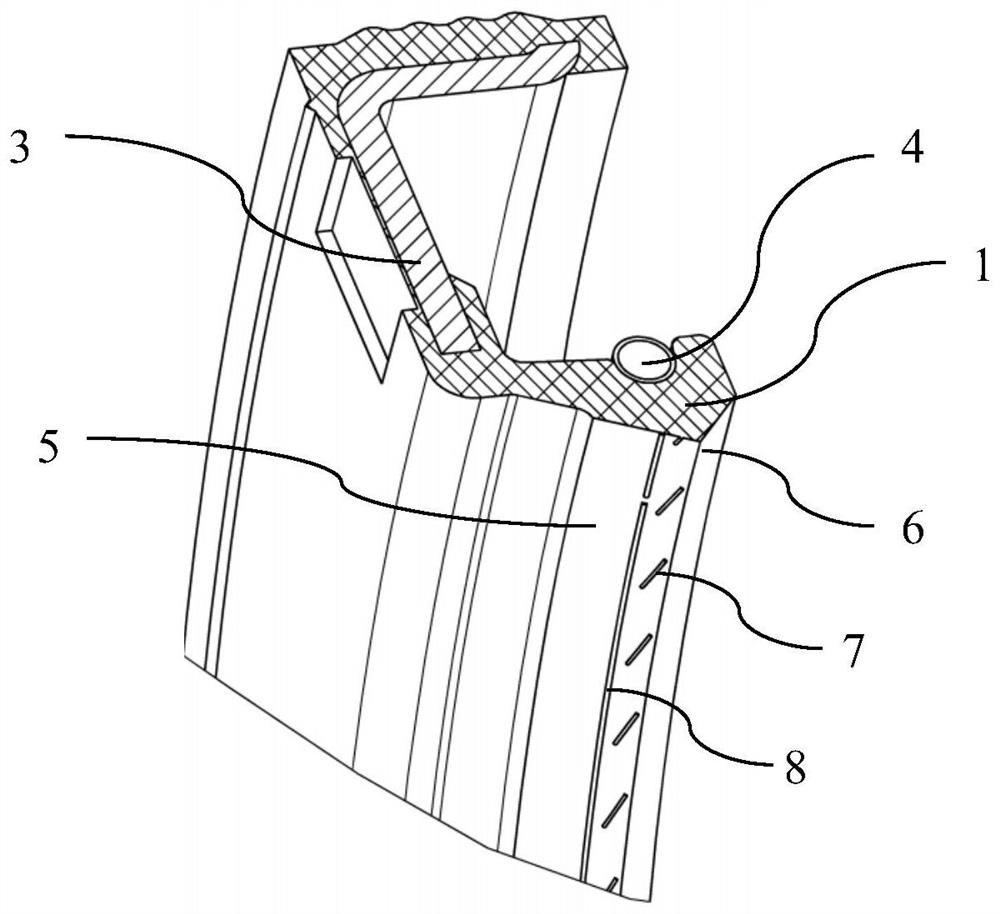

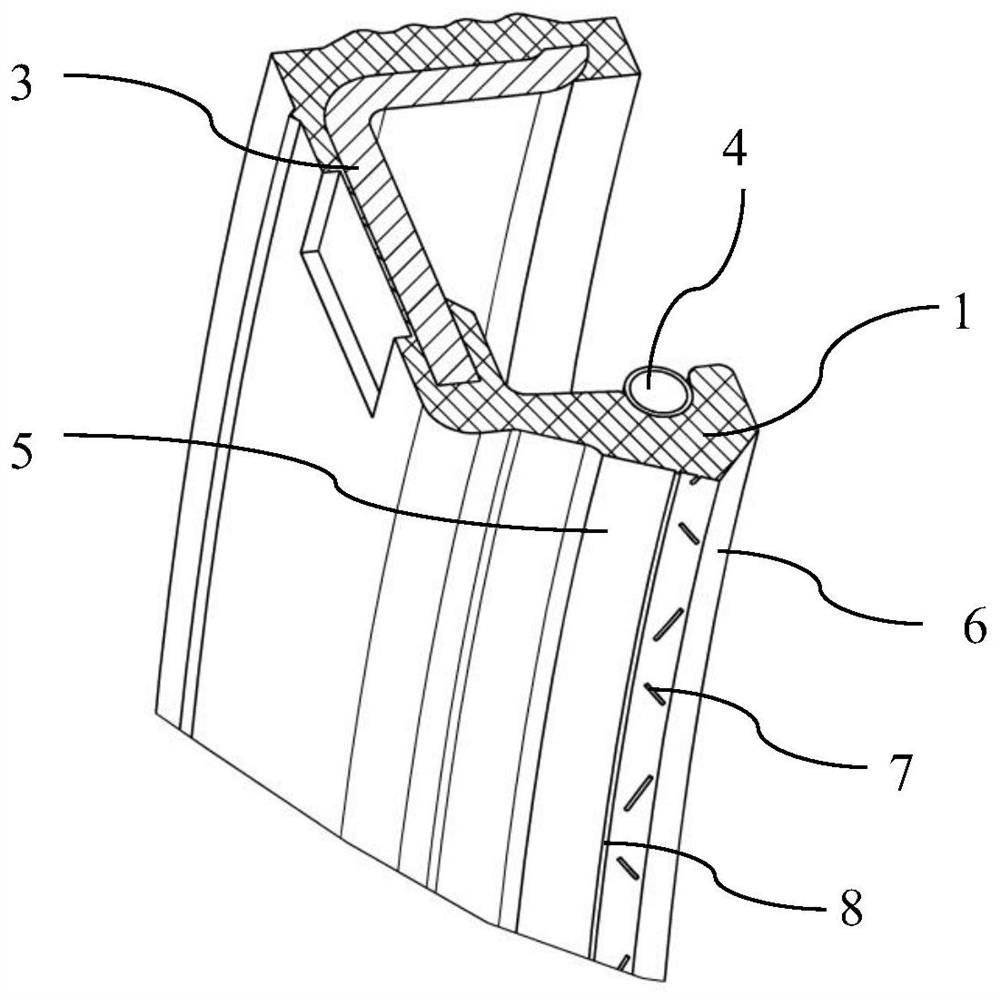

[0027] figure 1 is a partial perspective view of the sealing ring according to the first preferred embodiment. The sealing ring can be used for dynamic sealing of rotating shafts with bi-directional rotating conditions. especially if figure 1 As shown in the cross-section of the sealing ring in , the sealing ring includes an elastic sealing body made of elastomer, especially rubber, a skeleton 3 and a spring ring 4, wherein the elastic sealing body is at least partially covered here to support the sealing ring The skeleton 3.

[0028] The sealing ring according to the first embodiment forms by means of its elastic seal two sealing lips, namely a main lip 1 arranged on the fluid side and a dust lip 2 arranged on the air side. In this embodiment, the main lip 1 may abut against a rotating component (not shown) substantially radially, and the sealing portion formed by the main lip 1 and the rotating component may be formed on the outer peripheral surface of the rotating compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com