Novel static-ring structure of mechanical sealing device

A mechanical seal device and static ring technology, applied in the stuffing box field, can solve the problems of damage to the dynamic ring, increased production costs, and endangering equipment safety, and achieve the effects of improving lubrication conditions, improving working conditions, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

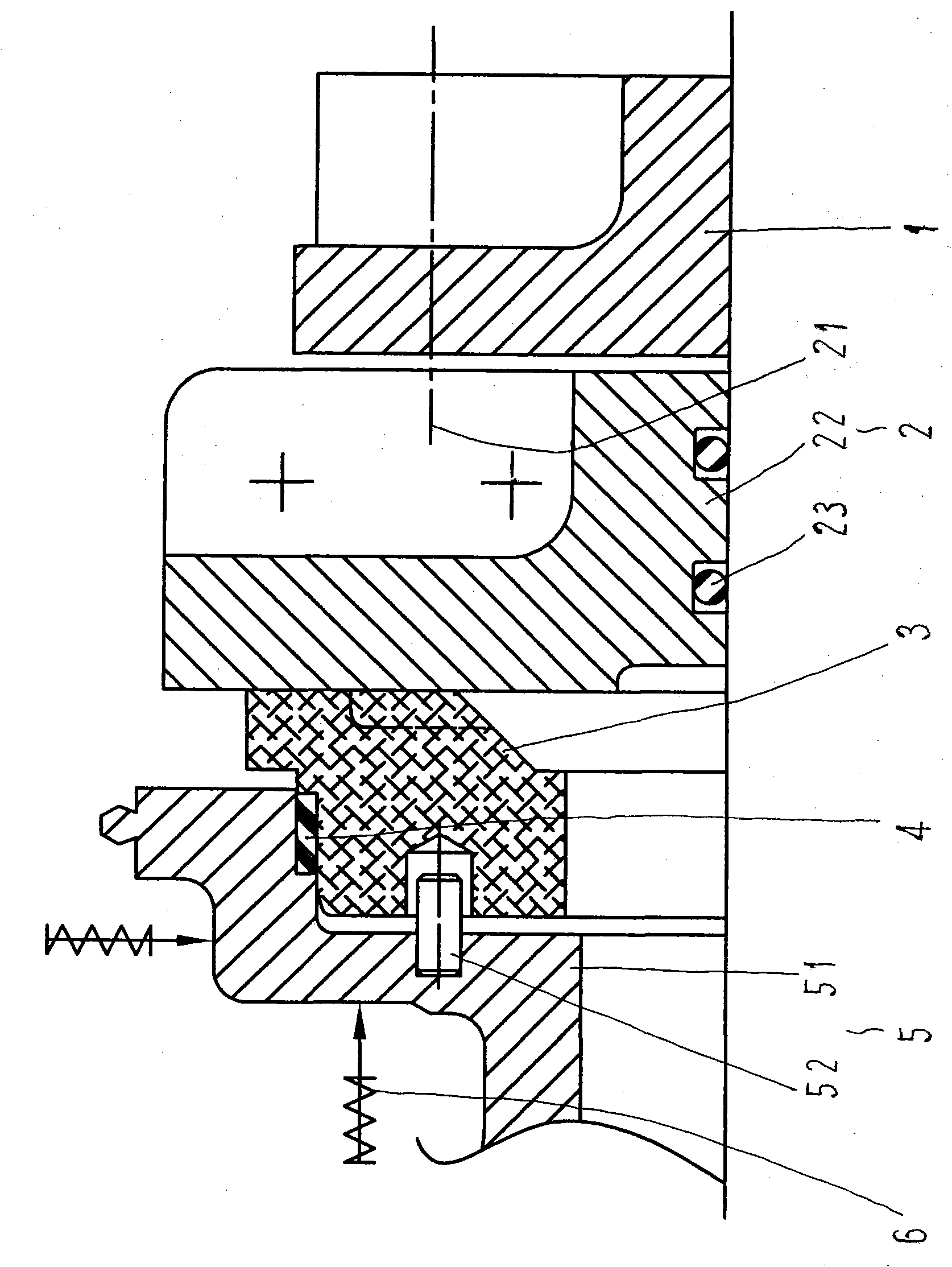

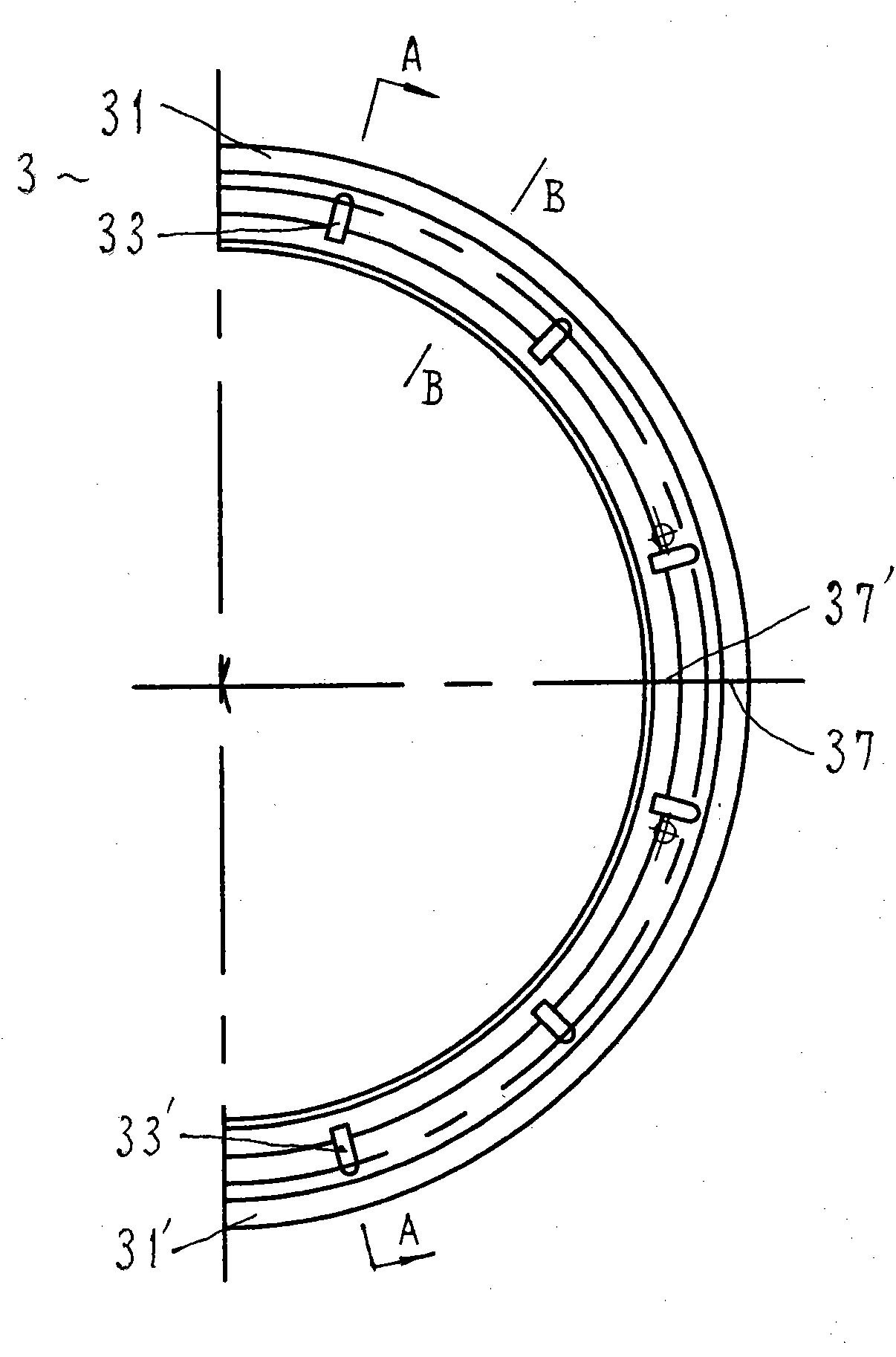

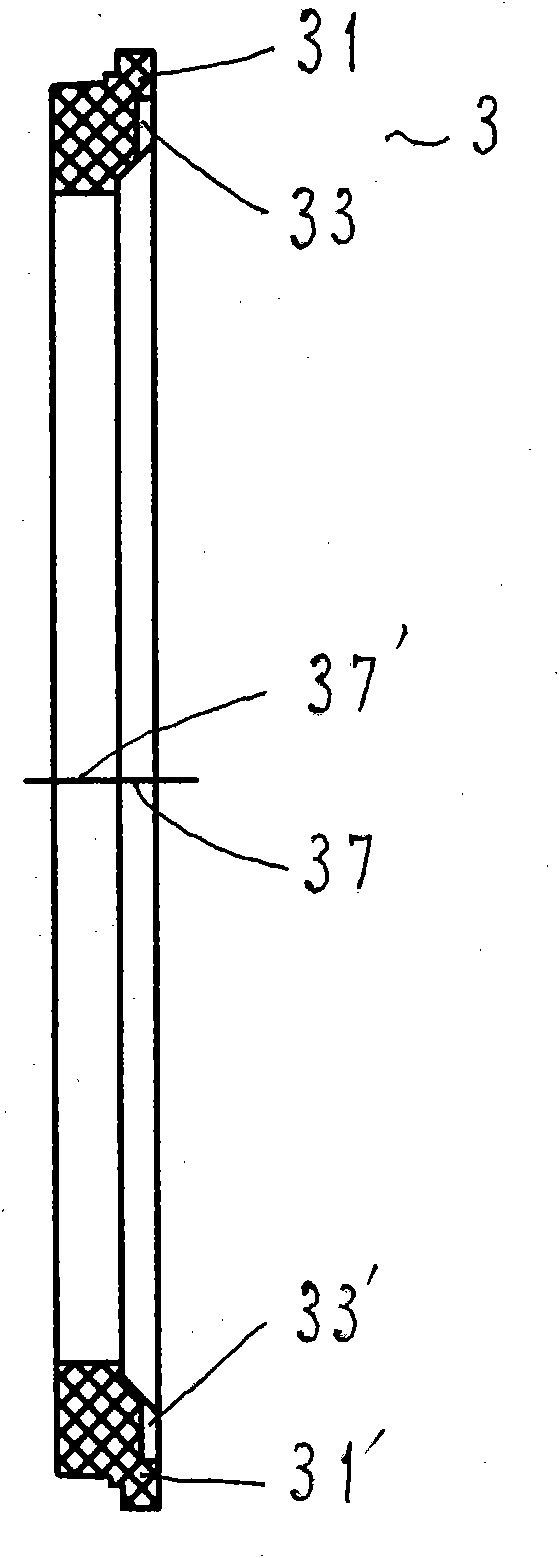

[0020] refer to figure 1 , the new mechanical seal device includes a driving ring 1, a moving ring 2, a static ring 3, an annular sealing strip 4, a static ring seat 5 and an elastic element 6. The above-mentioned components are the same or similar to the existing structure except the static ring 3. The ring 1 and the stern shaft are in driving connection, the driving ring 1 drives the moving ring body 22 of the moving ring 2 to rotate through the bolt 21, and a sealing ring 23 is provided at the joint between the moving ring body 22 and the stern shaft, and the sealing work of the moving ring body 22 The surface (i.e. the end face corresponding to the sealing working surface of the static ring 3) is a disc-shaped plane, the static ring 3 is the main component of the present invention, the static ring 3 is fixed on the static ring seat 5 through the annular sealing strip 4, and the static ring The seat body 51 of the seat 5 is provided with an anti-rotation pin 52 , and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com