Power high efficiency grinding head

A high-efficiency, grinding-head technology, used in grinding machines, grinding/polishing equipment, machine tools designed for grinding workpiece rotating surfaces, etc., can solve the problem of weakened spindle rigidity, poor macro quality of the grinding surface, and easy drift of the spindle axis. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

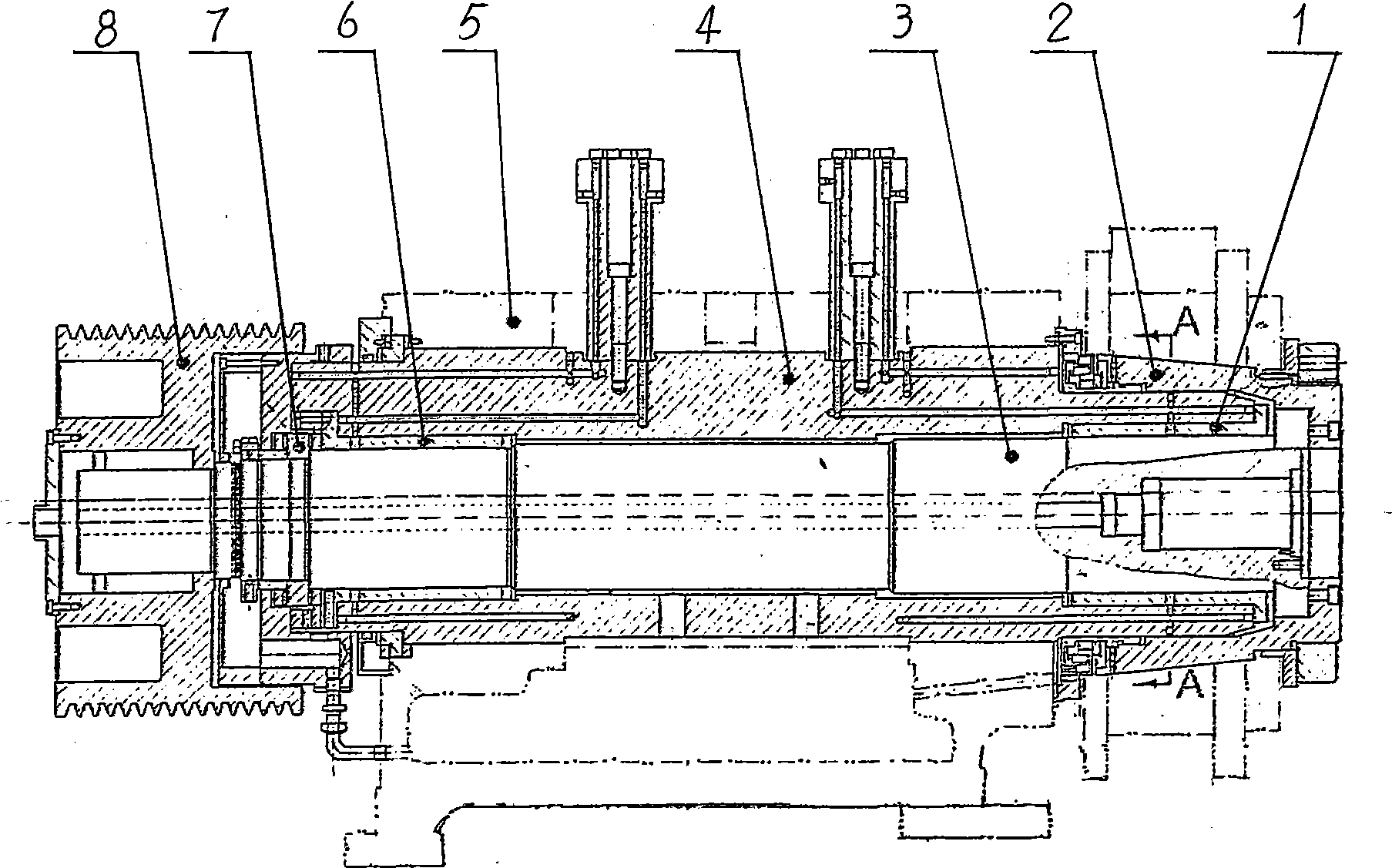

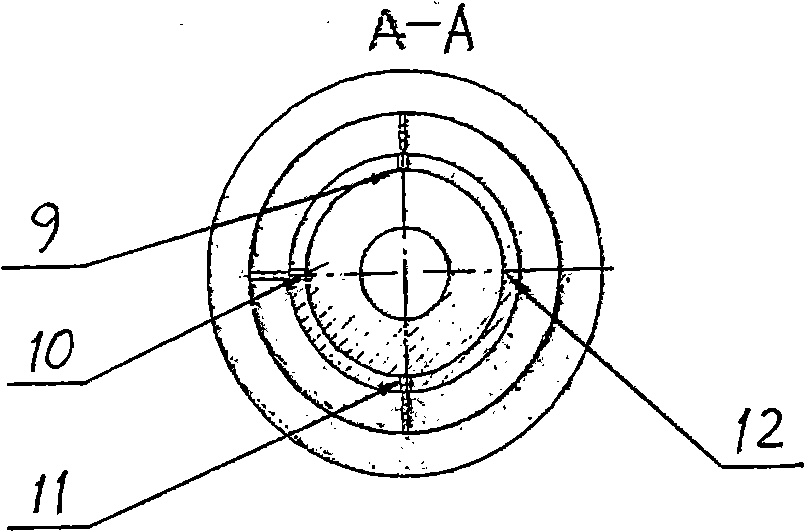

[0016] Such as figure 1 , figure 2 As shown, the main shaft 3 is installed in the eccentric sleeve 4, the dynamic and static pressure front bearing 1 is installed at the front end between the eccentric sleeve and the main shaft, the dynamic and static pressure rear bearing 6 and the rolling thrust bearing 7 are installed at the rear end, and then put into the mill frame shell together 5. Install the tapered sleeve 2 on the front end of the eccentric sleeve 4, and install the pulley 8 on the rear end of the main shaft 3. The structure of the oil chamber of the dynamic and static pressure bearing is 9 static pressures in the upper chamber, 11 static pressures in the lower chamber, 10 static pressures in the front chamber and 10 static pressures in the rear chamber. Chamber 12 dynamic pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com