Mechanical sealing structure of pearl-row-like annular groove zoning end face

A kind of end face mechanical seal and mechanical seal technology, applied in the direction of engine seal, mechanical equipment, engine components, etc., can solve the problems of complex structure, large leakage, etc., achieve wide application range, improve dynamic pressure effect, and improve wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

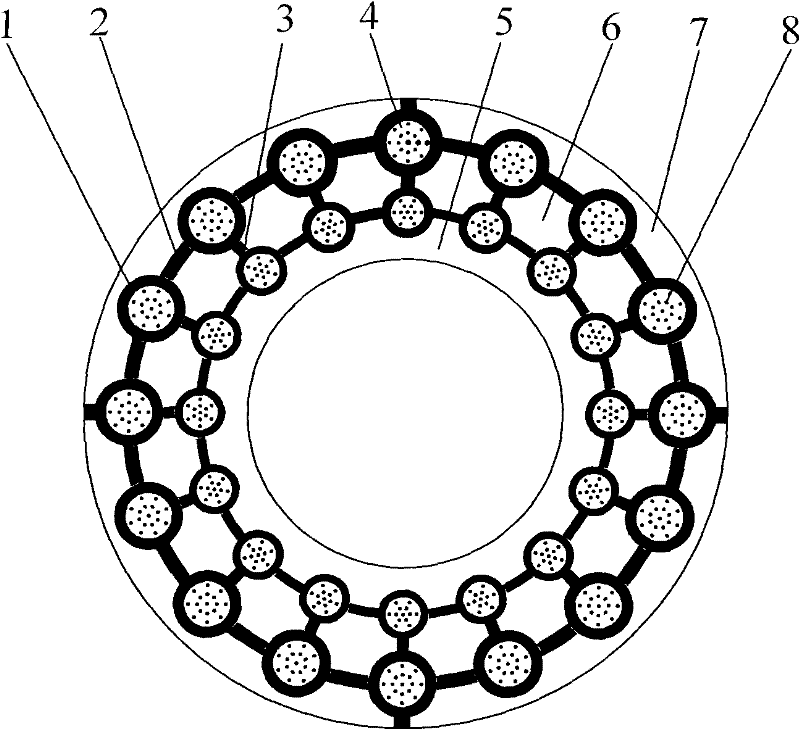

[0030] refer to figure 1 , like a pearl chain-shaped circular ring groove ring with an end-face mechanical seal structure, including a rotating ring and a static ring of a mechanical seal, at least one of the sealing rings in the rotating ring and the static ring is provided with holes symmetrical to the center of rotation. A pearl-chain-like annular band composed of several circular grooves, each circular groove 1 surrounds a circular boss 4, and annular sealing dams 5, 7 are provided on the inside and outside of the sealing end surface ; The annular grooves 1 on the same ring belt are communicated through the circumferential arc grooves 2 .

[0031] There are two or more annular bands, and the radii of the annular grooves 1 on different annular bands gradually decrease along the leakage direction of the sealing medium.

[0032] The radially adjacent annular grooves 1 on different annular belts communicate with each other through connecting grooves 3 . The connection groove...

Embodiment 2

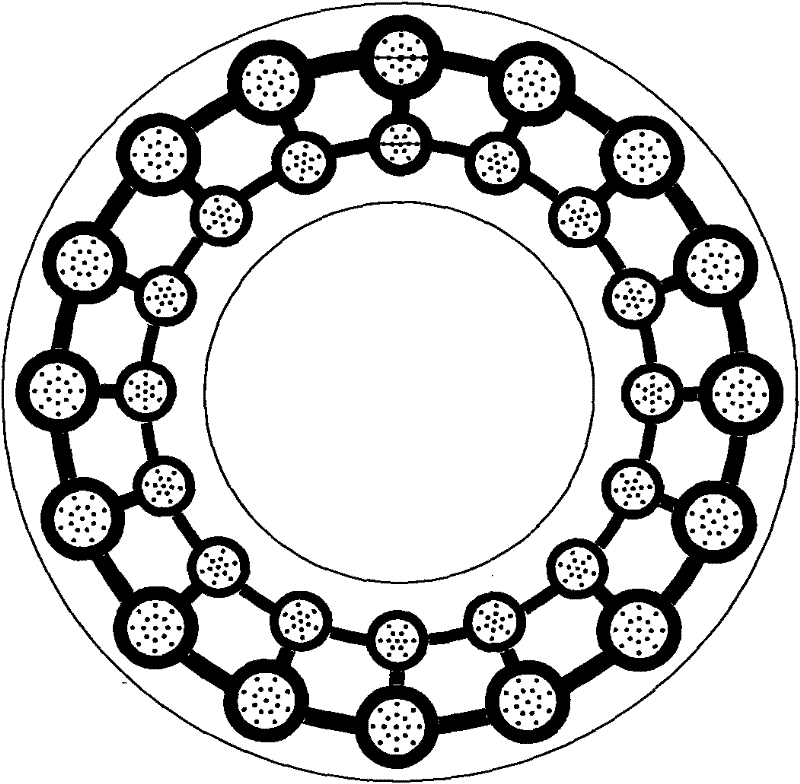

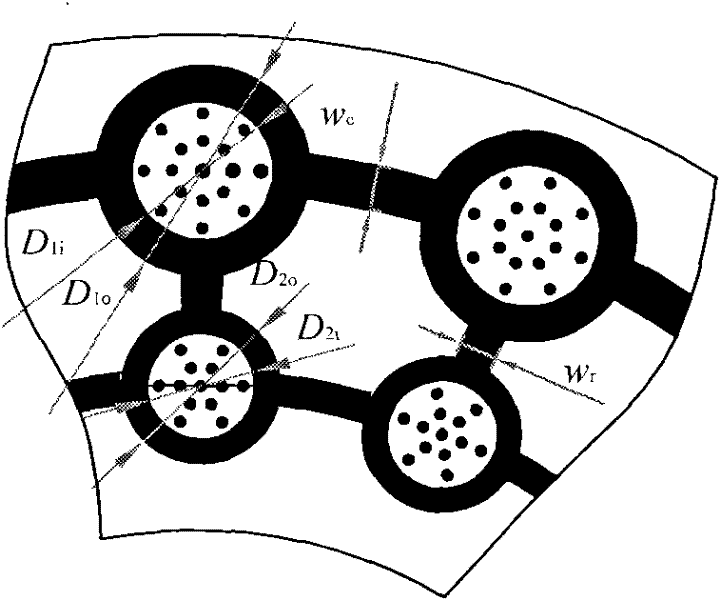

[0038] refer to figure 2 , image 3 The difference between this embodiment and the first embodiment is that the annular groove 1 on the outer ring belt is not connected to the high-pressure side of the sealing medium, which is suitable for low viscosity sealing medium; other structures and functions are the same as the first embodiment.

Embodiment 3

[0040] refer to Figure 4 The difference between this embodiment and the second embodiment is that the surface 6 of the boss area between the adjacent ring grooves is provided with micropores. This structure further improves the uniformity of pressure distribution of the end film, improves the opening force of the end face, and further absorbs fine particles in the medium. When the seal is only required to have excellent low-speed and low-pressure start-up performance, it can only communicate with the annular groove 1 on the same radius circle, see Figure 5 ; When the sealed medium is gas, it is only necessary to communicate with the circular groove 1 in the circumferential direction, and when the sealed medium is liquid, the effect of connecting the circular groove 1 in the radial direction will be better. Other structures and functions are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com