Laser cutting machine and working method thereof

A laser cutting machine and cutting machine technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high power consumption, low precision, and non-compliance with industrial requirements of the drive system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

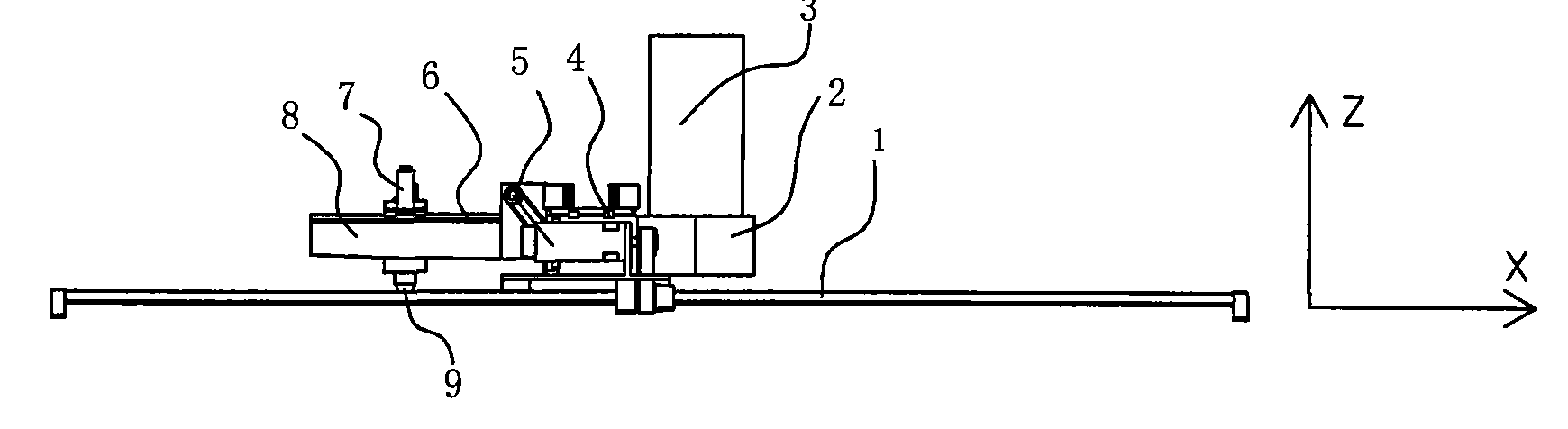

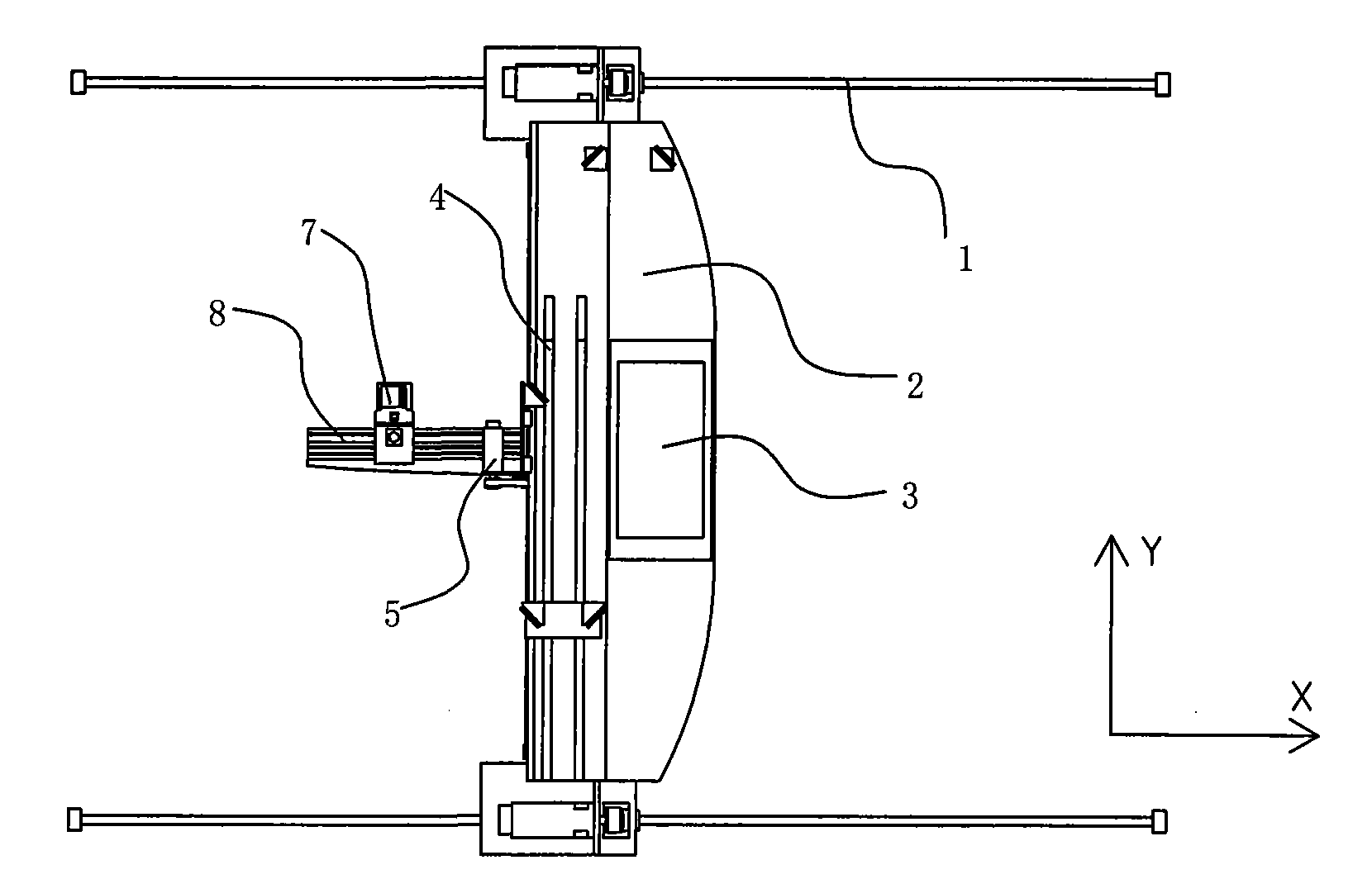

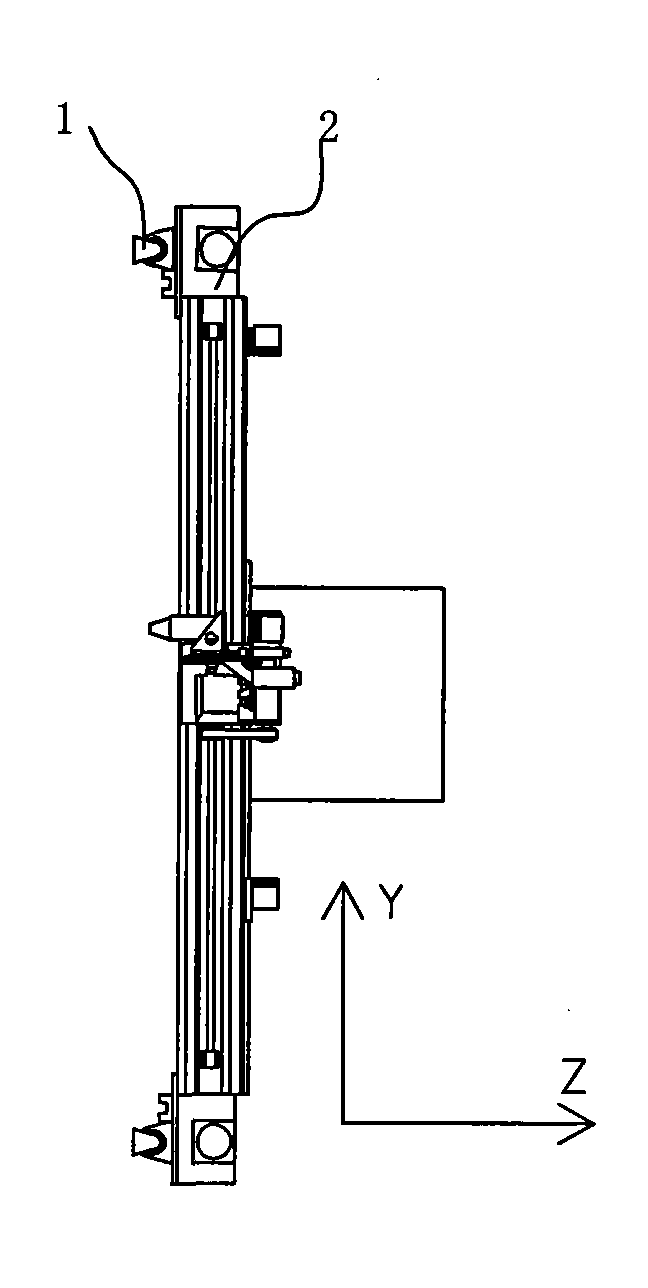

[0034] The present invention is as Figure 1-3 As shown, the cutting machine includes a machine base provided with an X guide rail 1 (which can be a lead screw), a main beam 2 provided with a Y guide rail 4 and a laser head base 7, the laser generator 3 is arranged on the main beam 2, and the laser The head 9 is arranged on the laser head base 7 through the Z-direction guide rail, the main beam 2 is movably connected with the X guide rail 1 on the machine base, and it also includes a cantilever beam 8 for the laser head 9 to realize short-range action in the X-direction; The cantilever beam 8 is provided with an X short guide rail 6; the root of the cantilever beam 8 is movably connected to the Y guide rail 4 on the main beam 2, so that the cantilever beam 8 can move in the Y direction; the laser head seat 7 is movably connected to the X short guide rail 6, and realizes relative movement through the laser head seat driving mechanism 5.

[0035] It also includes a controller, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com