No-drifting high accurate open type static pressure guide rail

A static pressure guide rail, high-precision technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of poor rigidity, large oil film thickness, etc., and achieve the effect of improving the rigidity of the oil film and increasing the rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

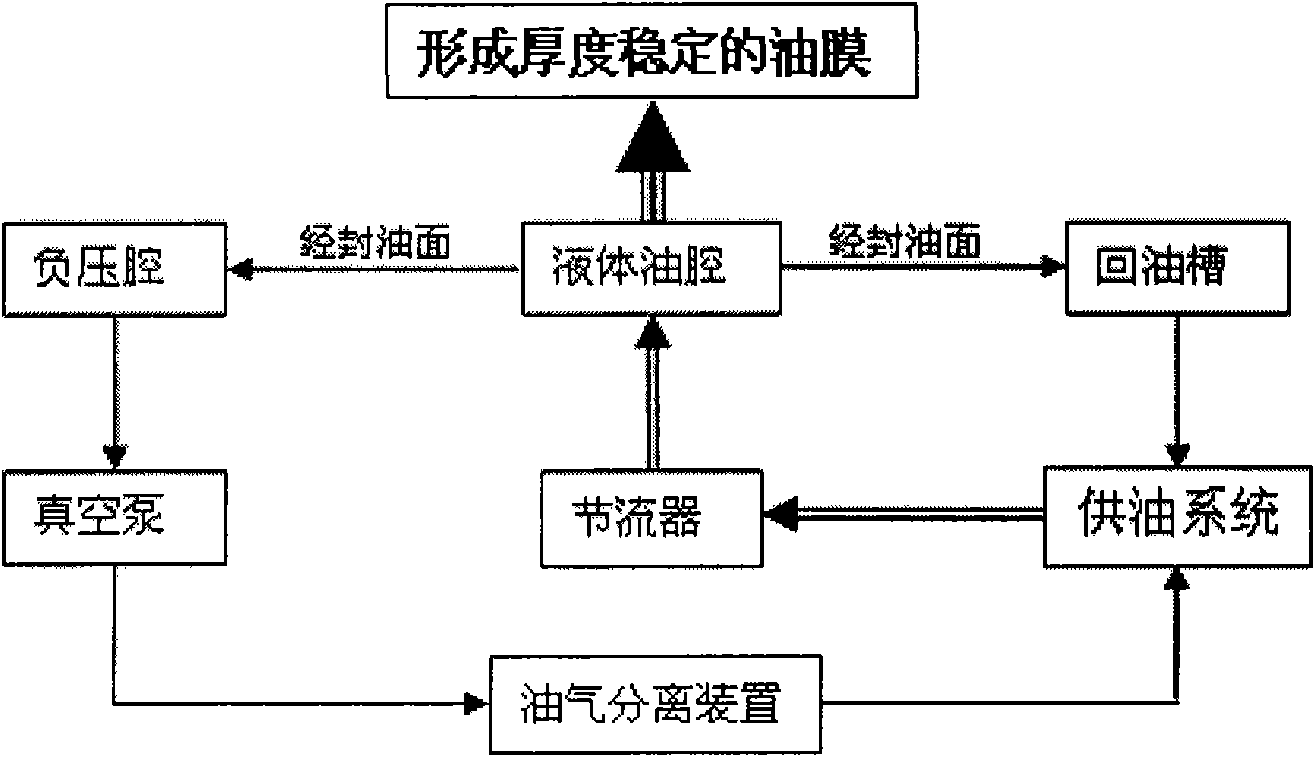

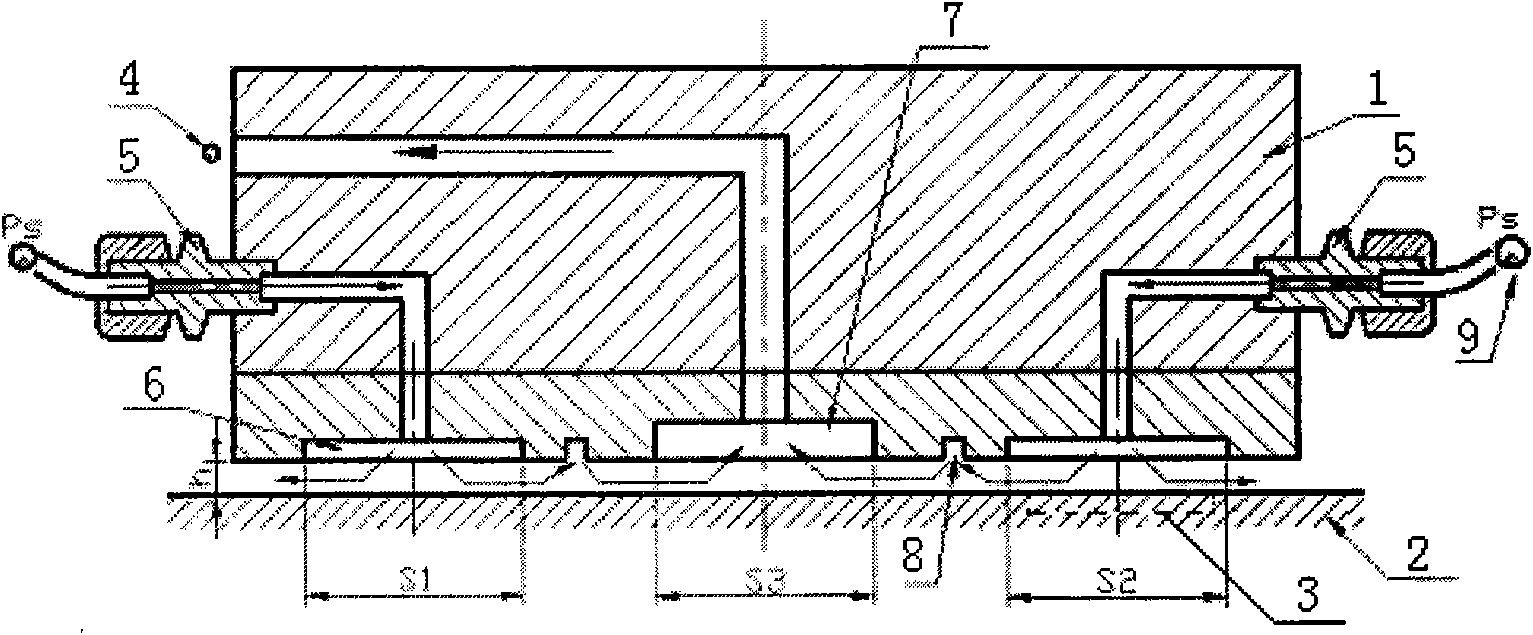

[0015] Such as figure 2 As shown, a drift-free high-precision open hydrostatic guide rail includes a planar floating guide rail 1 and a supporting guide rail 2. The floating guide rail 1 is placed on the supporting guide rail 2. The contact between the floating guide rail 1 and the supporting guide rail 2 There is a static pressure oil chamber 6 and a circular negative pressure chamber 7 on the surface. The negative pressure chamber 7 is opened between the two static pressure oil chambers 6. In order to ensure the stable flow of the oil supply system 9, a constant pressure supply is adopted. The oil system is connected to the static pressure oil chamber 6 through the restrictor 5, the negative pressure chamber 7 is connected to the jet vacuum pump 4, and the vacuum pump is connected to the oil supply system 9 through the oil-gas separation device, and the opening between the floating guide rail 1 and the support guide rail 2 There is an oil return groove communicated with the...

Embodiment 2

[0040] The difference between the second embodiment of the drift-free high-precision open static pressure guide rail of the present invention and the first embodiment is that the floating guide rail 1 and the support guide rail 2 are V-shaped guide rails, and the static pressure oil chamber 6 and the negative pressure chamber 7 are symmetrically arranged on the two planes of the "V" shape, the negative pressure chamber 7 is square, and the oil return groove is composed of the longitudinal oil return groove 8 opened on the surface of the floating guide rail 1 and the transverse oil return groove 3 opened on the support guide rail 2 composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com