Material grinding and conveying module and drying chamber thereof

A technology for conveying modules and materials, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., and can solve problems that affect the drying effect and operation stability, loss, and inability to work stably for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0063] The first embodiment: (material rolling conveying module containing two-layer conveying platform)

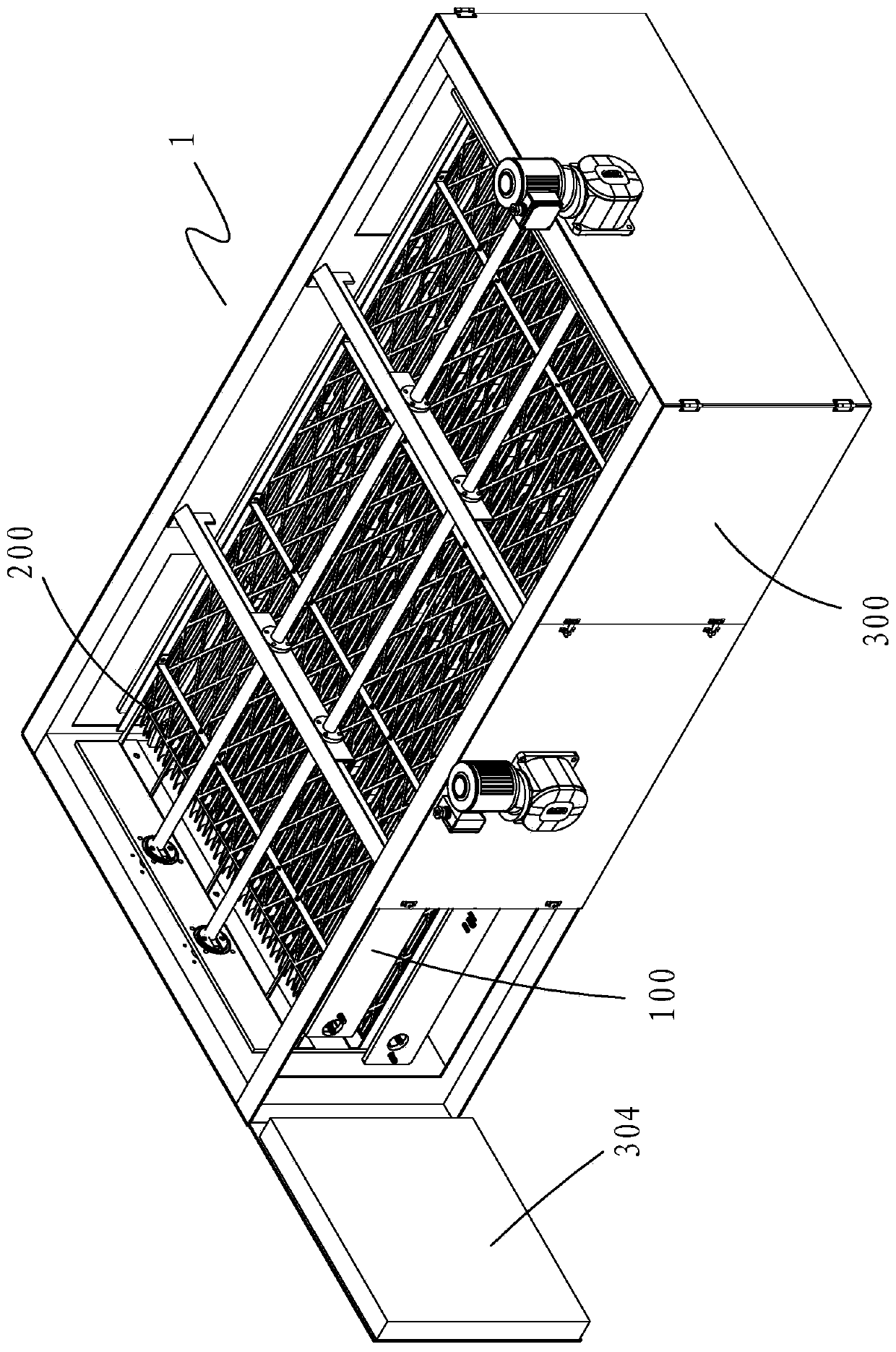

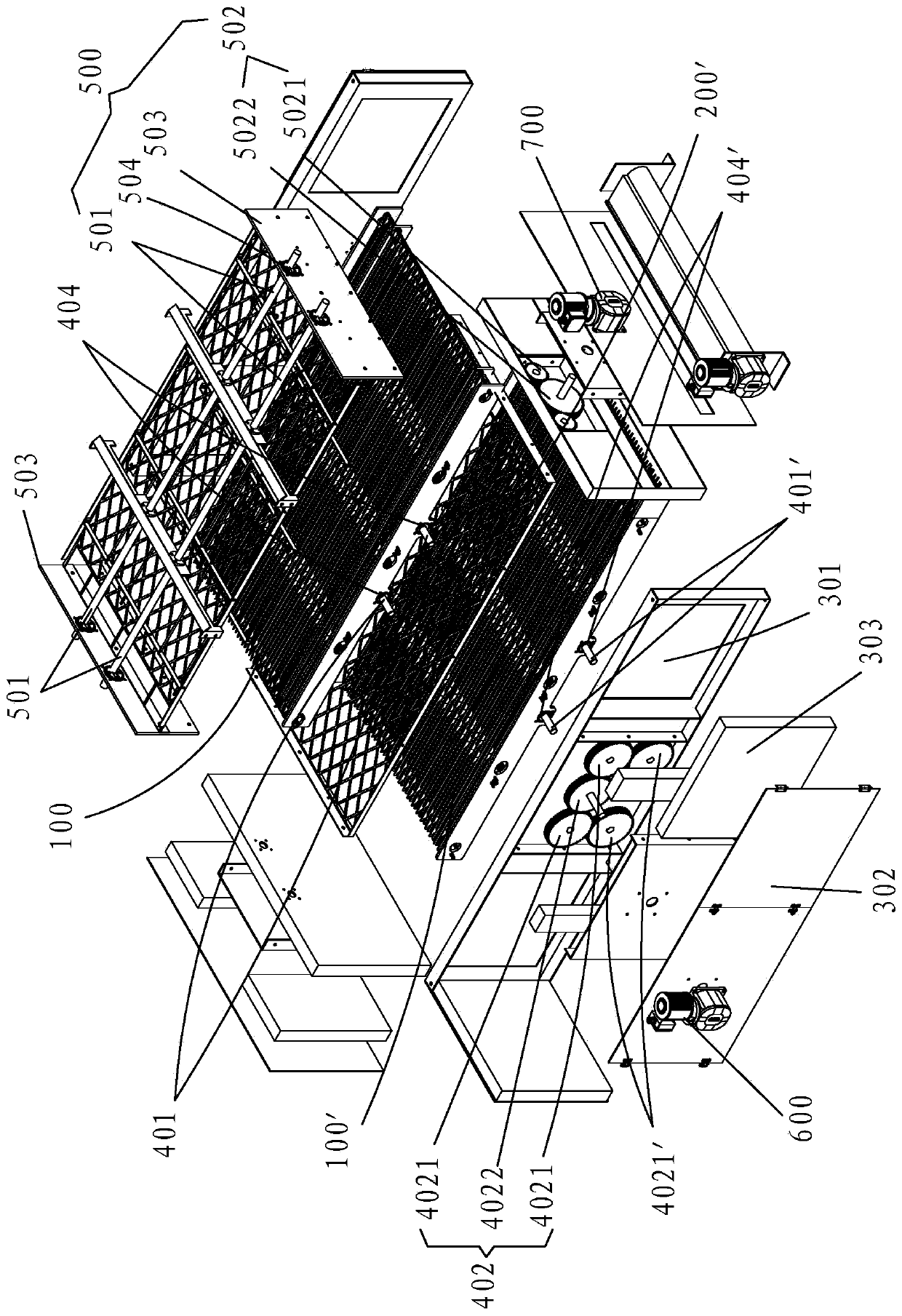

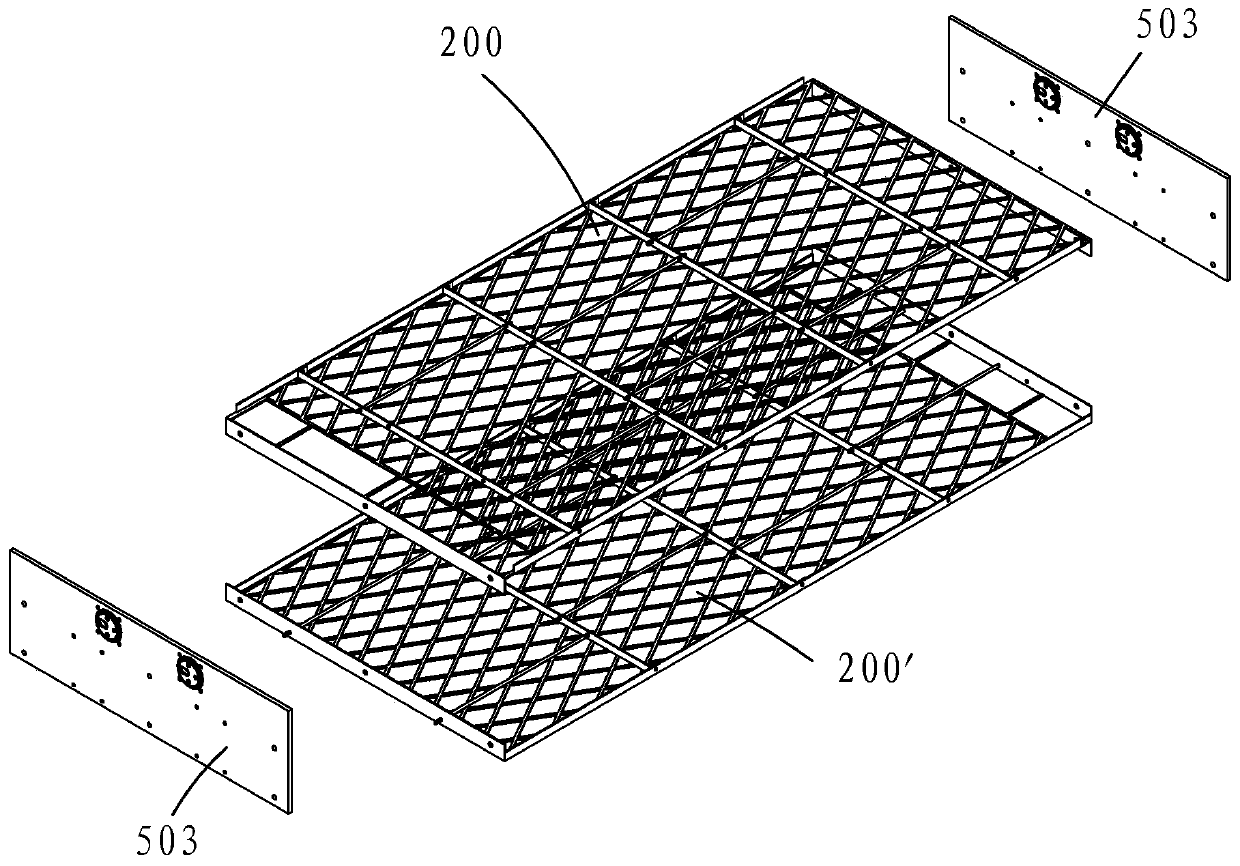

[0064] Such as Figure 1 to Figure 3 As shown, a material rolling conveying module 1 includes conveying platforms 100, 100' composed of two layers of stacked grating components, and a rolling platform 200, 200' is arranged above each conveying platform 100, 100', and Support frame 300 . The conveying platforms 100, 100' composed of grid bar components are driven by the first driving mechanism 400 to perform reciprocating synchronous circular motions, carrying and propelling the materials; the rolling platforms 200, 200' are driven by the second driving mechanism 500 to push the materials Vertical reciprocating synchronous circular motion. The supporting frame 300 is used to support the first driving mechanism 400 and the second driving mechanism 500 .

[0065] Among them, the specific structure of the conveying platforms 100 and 100' composed of the grating components ...

no. 2 example

[0083] The second embodiment: (containing the drying chamber of the material rolling conveying module)

[0084] Such as Figure 4 with Figure 5 As shown, a drying chamber 2 includes: four (in the first embodiment) material rolling and conveying modules 1 arranged in layers.

[0085] The four material rolling and conveying modules 1 arranged in layers form a steamer structure, and the support frame 300 of each material rolling and conveying module 1 is locked and fixedly connected up and down.

[0086] An upper heat insulation layer 305 is arranged above the support frame 300 of the material rolling conveying module 1 located on the uppermost layer.

[0087] A lower insulation layer 306 is provided at the bottom of the supporting frame 300 of the material rolling conveying module 1 at the bottom.

[0088] The upper heat insulation layer 305 , the lower heat insulation layer 306 , and the supporting frame 300 of each layer form a closed box, which encloses all the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com