Wheel

A wheel and wheel body technology, applied in the direction of wheels, vehicle parts, transportation and packaging, etc., can solve problems such as high running noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

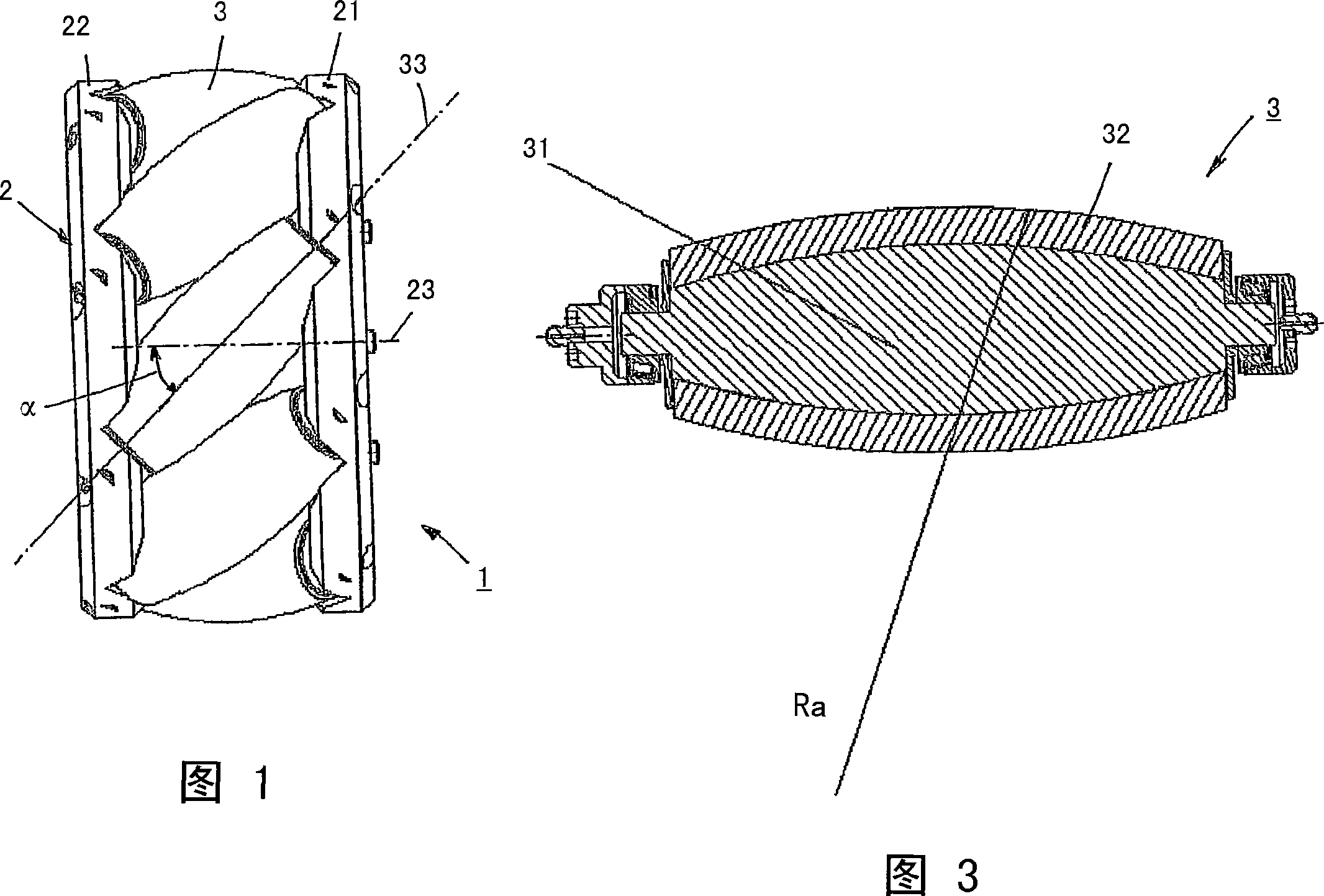

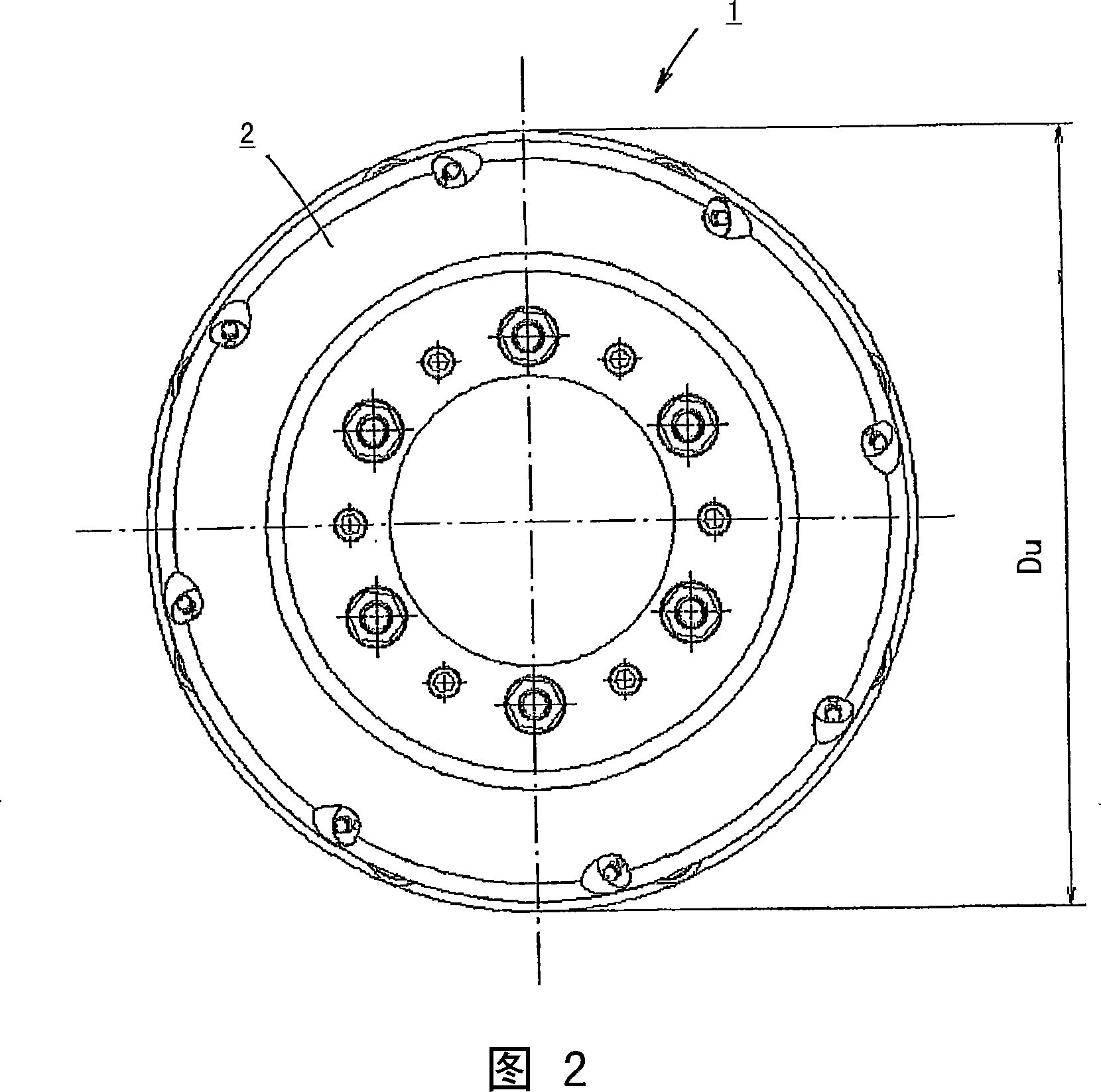

[0013] FIG. 1 shows a front view of a wheel 1 with a wheel body 2 having two support components 21 , 22 which are formed by discs spaced apart from one another. The support members 21, 22 can be driven by a drive device not shown and are fixedly connected to each other. The wheel body 2 is arranged to be rotatable in both directions about its axis of rotation 23 .

[0014] Between the support members 21 , 22 fixedly connected to each other, roller bodies 3 arranged equidistant from each other are arranged. The roller body 3 has a drum-shaped outer contour, and its rotation axis 33 forms an angle α with the rotation axis 23 of the wheel body 2 , preferably, α is 45°. The roller body 3 is freely rotatably arranged between the support members 21, 22, and the outer contour of the roller body 3 slightly protrudes beyond the outer periphery of the support members 21, 22, thereby forming a support for the wheel 1 on a foundation not shown. surface and rolling surface.

[0015] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com