Combined linear motor end cover

A linear motor and combined technology, applied in the field of motors, can solve the problems of high processing cost and difficult processing of motor parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

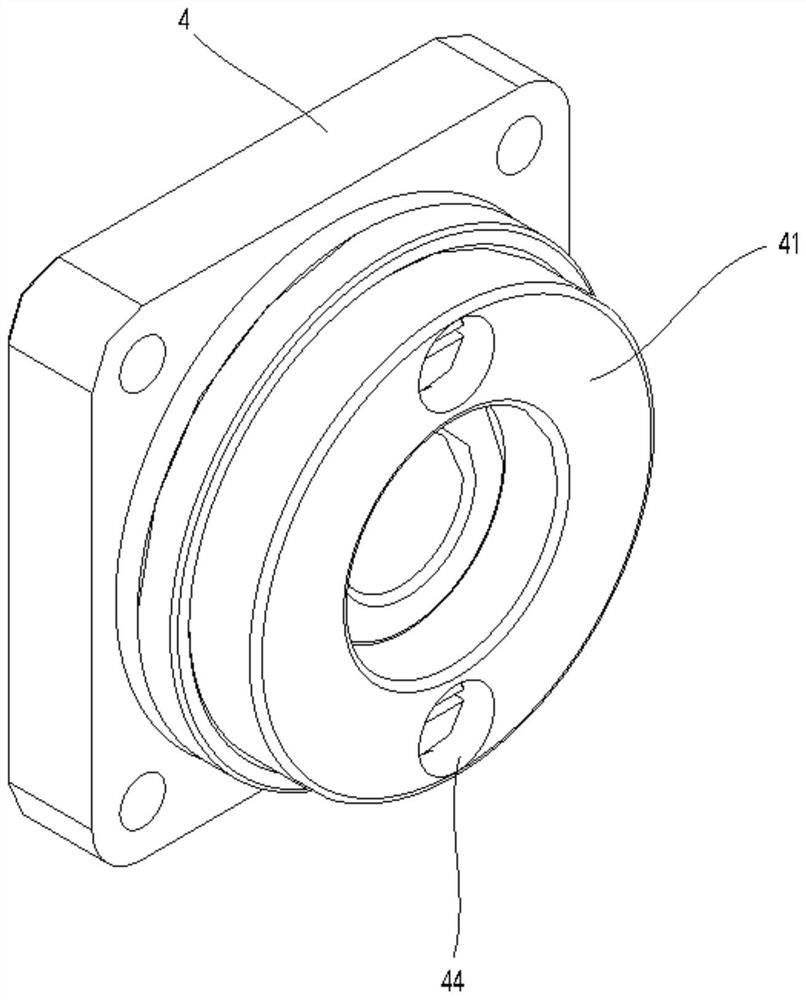

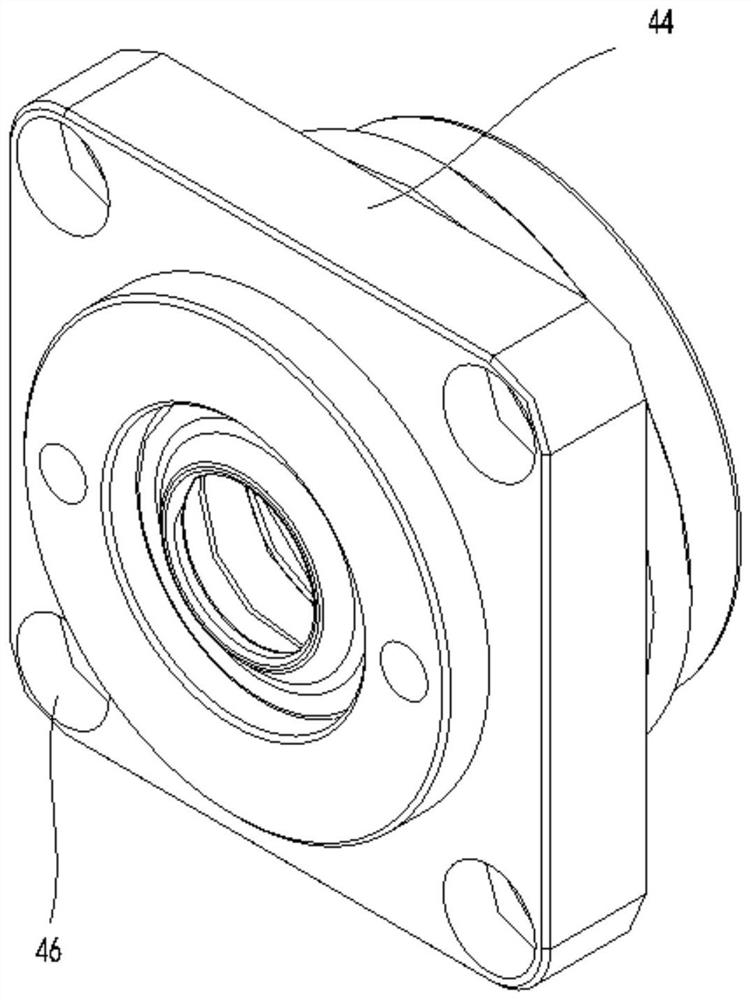

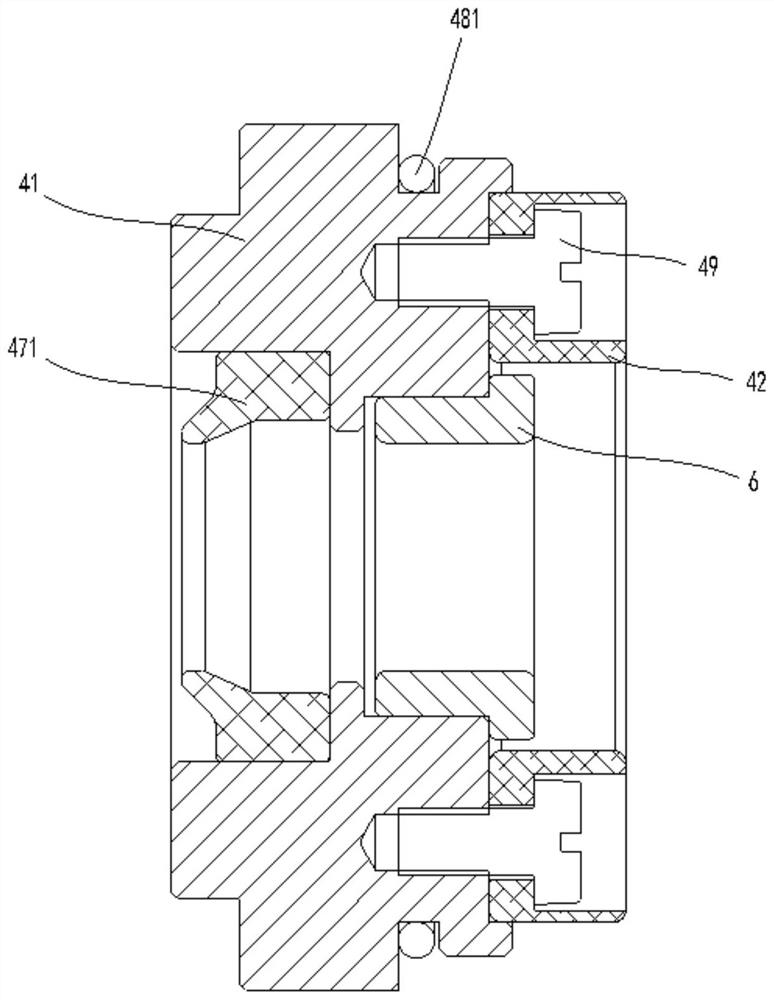

[0040] A combined linear motor end cover, such as Figure 1 to Figure 5 as shown,

[0041] Including end cover body 41, sliding sleeve 6 and limit ring 42;

[0042] The sliding sleeve 6 is arranged in the end cover body 41, the sliding sleeve 6 is slidably connected with the mover 2 and supports the mover 2, and the limit ring 42 is arranged in the end cover body 41 close to the motor body 1 side, used to limit the travel of mover 2.

[0043] The combined linear motor end cover provided by the embodiment of the present invention not only has the functions of dustproof and protection, but also supports the operation of the mover 2 by setting the sliding sleeve 6 for the mover 2 to slide, and the limit ring 42 can The mover 2 is limited, and no additional limit mechanism is required, which can simplify the overall structure of the tubular linear motor and reduce the volume of the linear motor, so that the linear motor can be applied to occasions that require relatively strict ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com