A tubular linear motor mover

A linear motor and mover technology, applied in the field of motors, can solve the problems of high cost and complex structure of tubular linear motors, and achieve the effect of reasonable structure, small volume and reduced space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

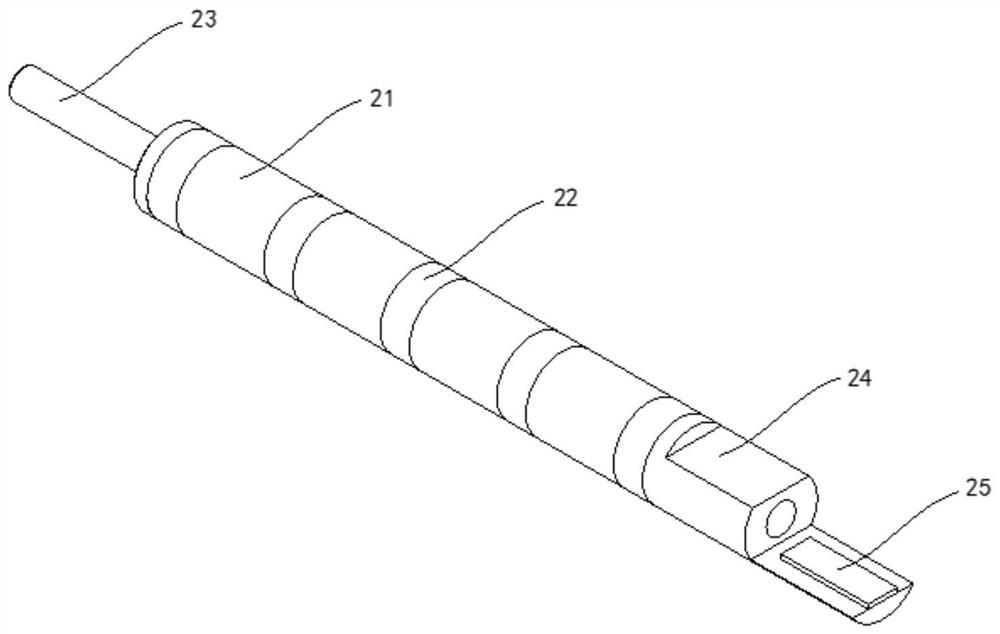

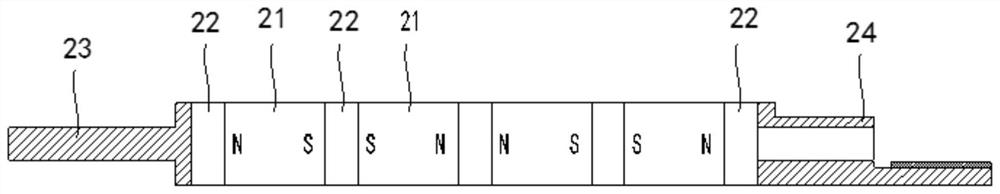

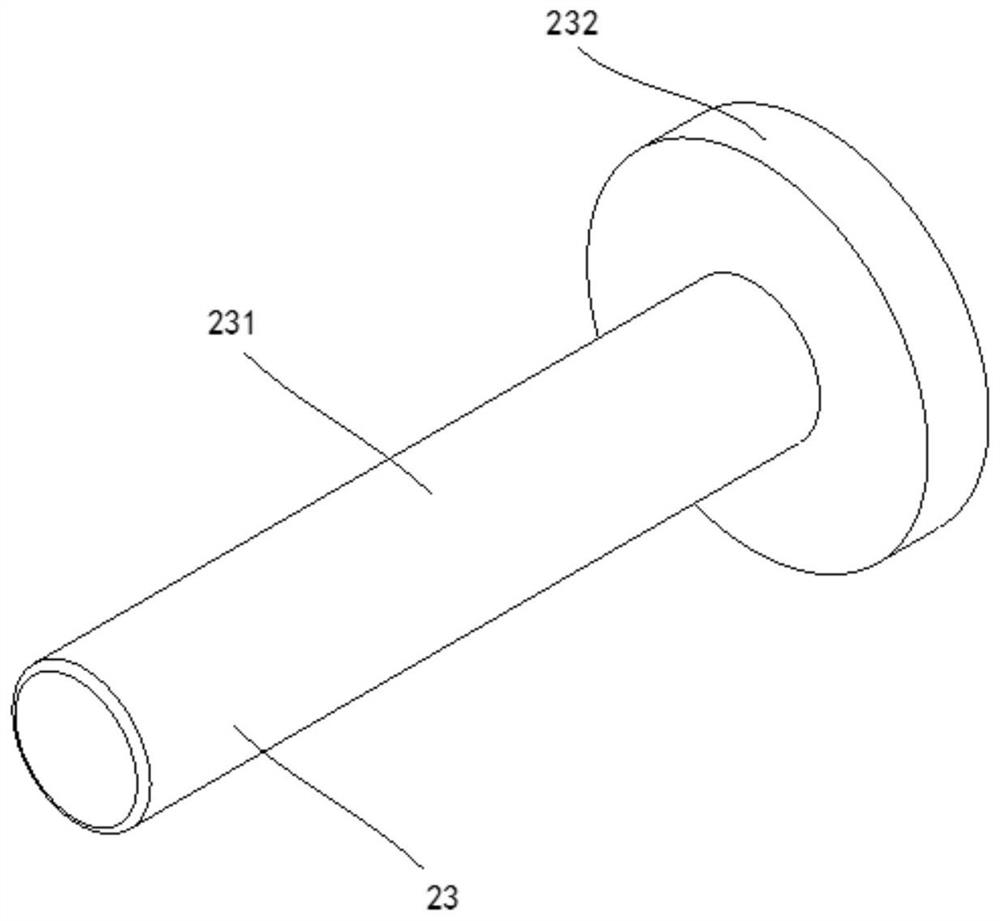

[0039] A tubular linear motor mover, such as Figure 1 to Figure 4 shown,

[0040] Including permanent magnet 21, iron core 22 and mandrel;

[0041] The iron cores 22 and the permanent magnets 21 are arranged alternately, so that the permanent magnets 21 are arranged between the iron cores 22 , the magnetic poles of the two adjacent permanent magnets 21 are opposite to each other, and the mandrels are arranged at the two ends of the magnets. The iron core 22 is away from the side of the permanent magnet, and the core shaft is slidably connected with the sliding sleeve 6 provided on the stator.

[0042] The tubular linear motor mover provided by the embodiment of the present invention can not only provide a magnetic field for the linear motor, but also can directly support the mover 2 on the sliding sleeve 6 of the stator through the mandrel to perform reciprocating linear motion without going through an intermediate conversion mechanism To directly generate linear motion, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com