Six-freedom-degree parallel machine arm driven by tubular linear motors and control method of six-freedom-degree parallel machine arm

A linear motor, degree of freedom technology, applied in the direction of AC motor control, control system, electric components, etc., can solve the problems of large size and complex mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

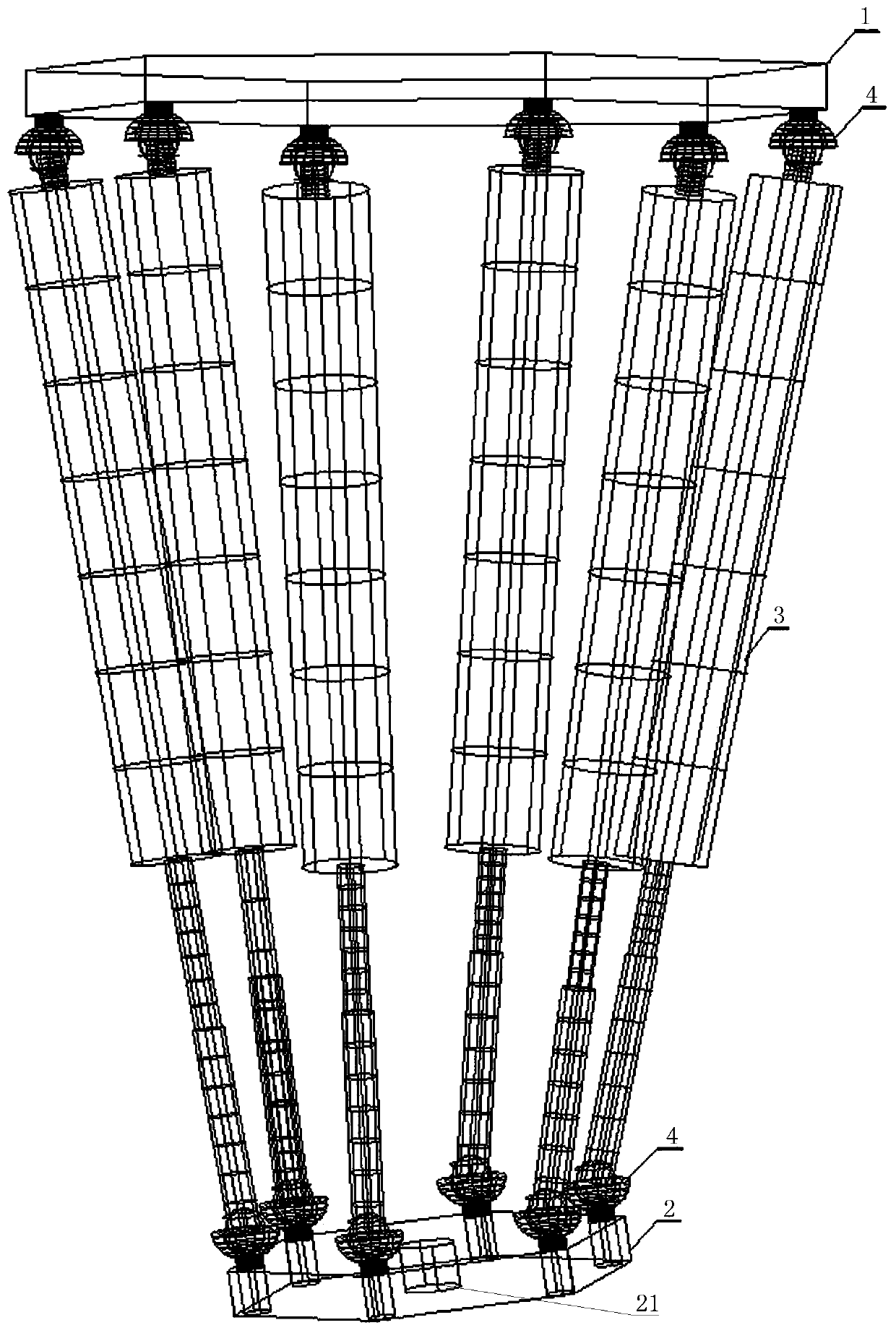

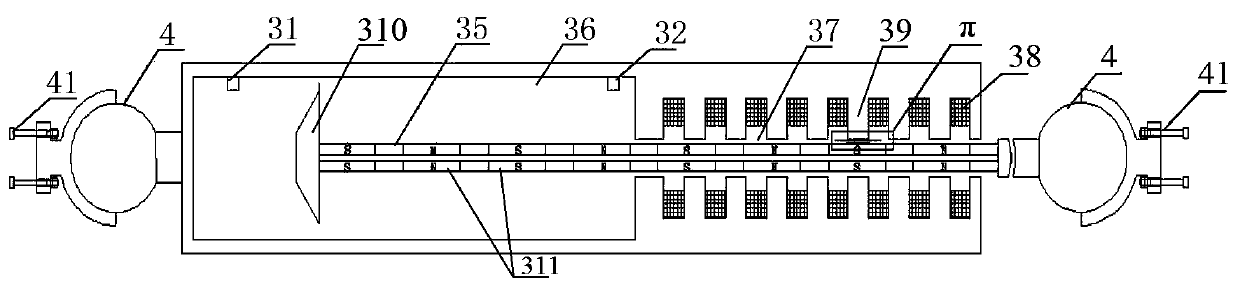

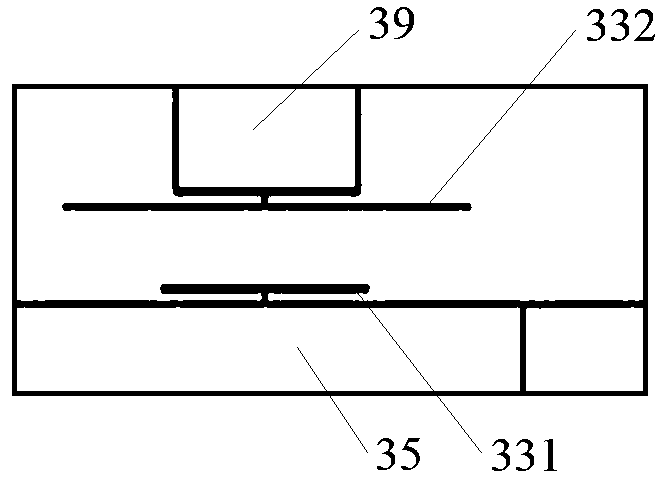

[0065] Such as figure 1 , figure 2 and Figure 7 As shown, a six-degree-of-freedom parallel robotic arm driven by a tubular linear motor includes a static platform 1, a moving platform 2, an upper limit photoelectric sensor 31, a lower limit photoelectric sensor 32, a grating ruler sensor 33 and a parallel controller 5. A plurality of tubular linear motors 3 are evenly distributed between the platform 1 and the moving platform 2. In this embodiment, the tubular linear motors 3 adopt six tubular permanent magnet synchronous linear motors, and each tubular linear motor 3 includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com