Conveyor system switch using tubular linear induction motor

A technology of linear induction and electric motor, applied in the direction of propulsion system, electric components, conveyor objects, etc., can solve the problems of complex pipeline supply system and compressor, high maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

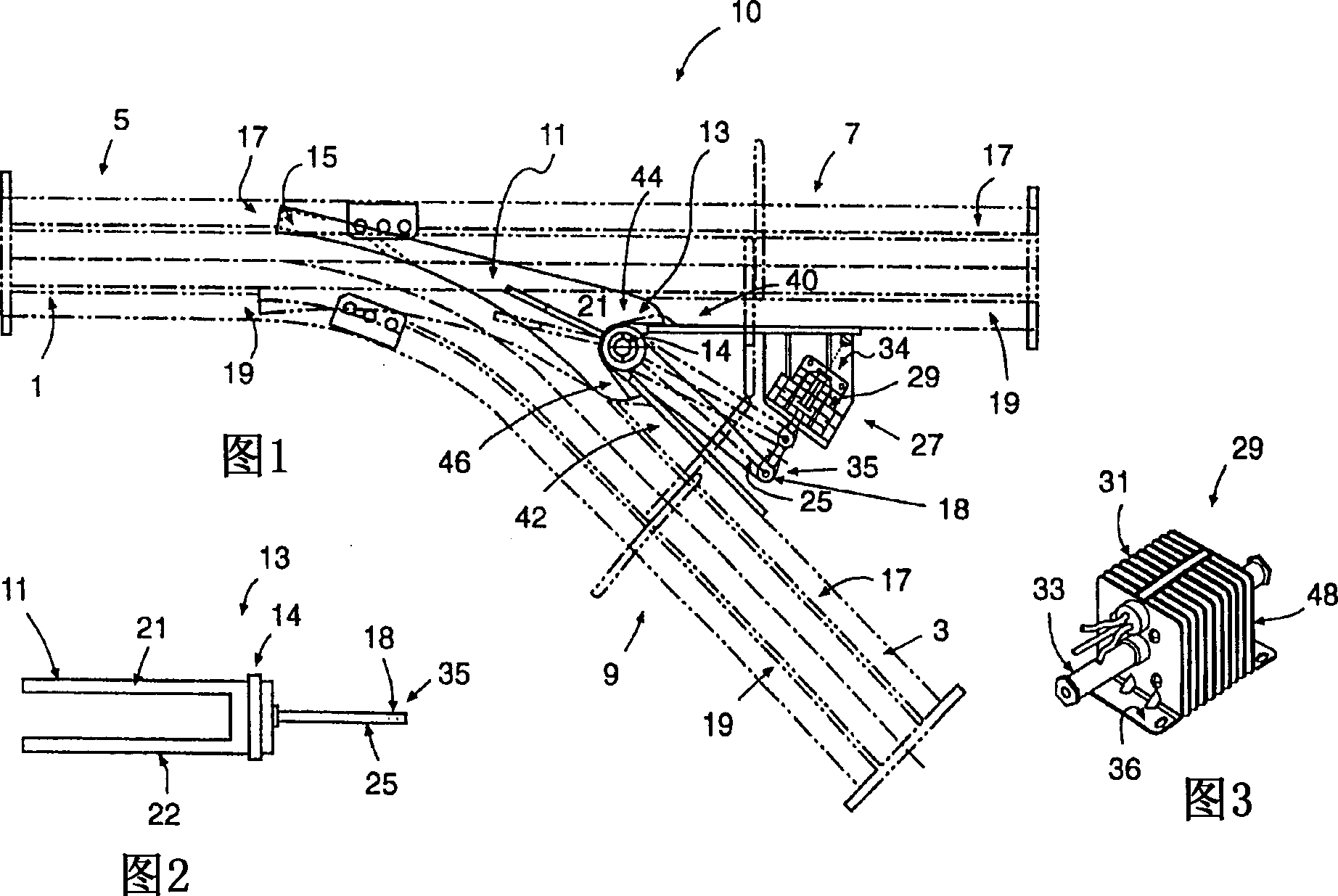

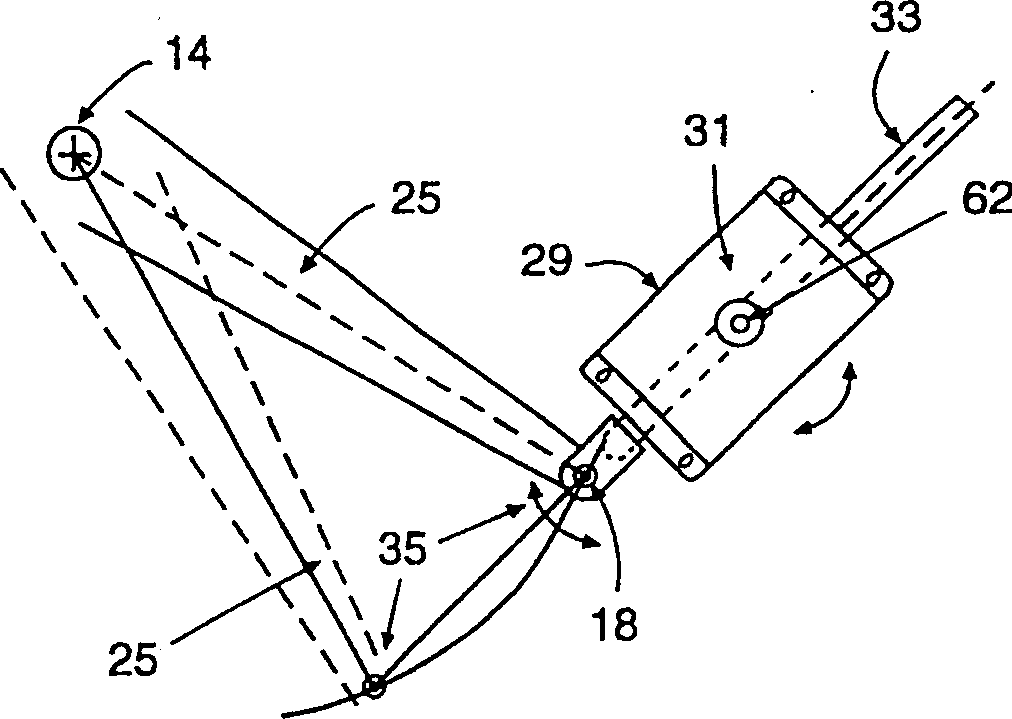

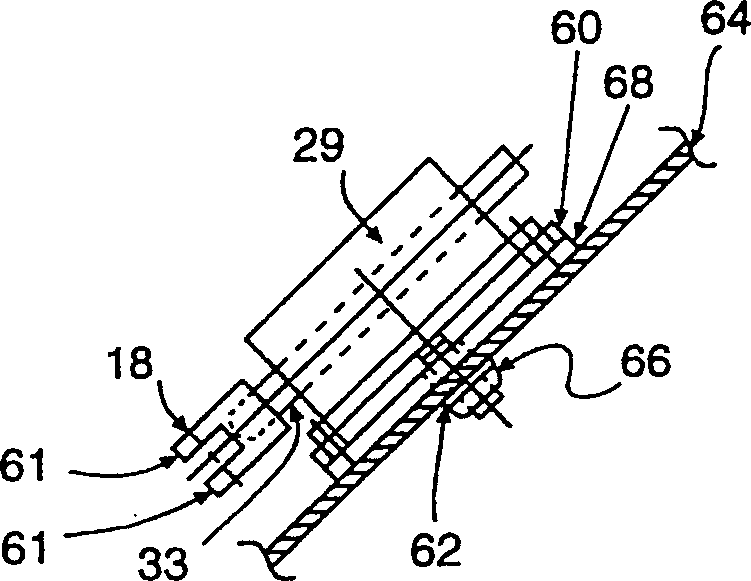

[0027] In FIG. 1, one embodiment of the present invention is a switch assembly 10 for use in a system switchable between powered and non-powered drives. Typically, these systems include powered and non-powered tracks. The chain moves along the power-driven track, and the trolley that supports the conveying object, such as a car body slide or a car body carrier, moves along a non-power-driven track. The chain is driven by the driving device, and the chain drives the trolley through the chain buckle. Powered and non-powered conveying systems are well known in the art and, therefore, will not be described in detail here. Although the turnout apparatus of the present invention has been described as an example for use in a system switchable between powered and non-powered drives, it will be understood that the invention is not limited to use with such systems. Elevated powered and non-powered systems, and other conveyor systems where conveyor components move along a track or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com