Pressing seat assembly assembling device for automatic production of flusher

An automatic production and assembly device technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as liquid leakage at the liquid outlet, no limit measures for pressing the handle, and fixed aperture size of the liquid outlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further illustrated by the following examples.

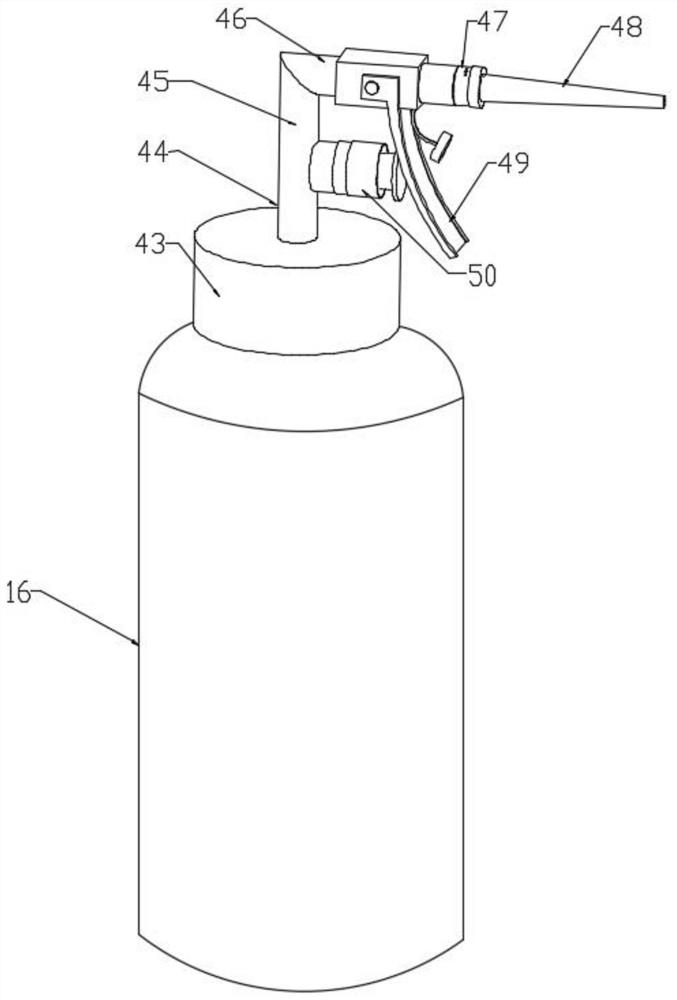

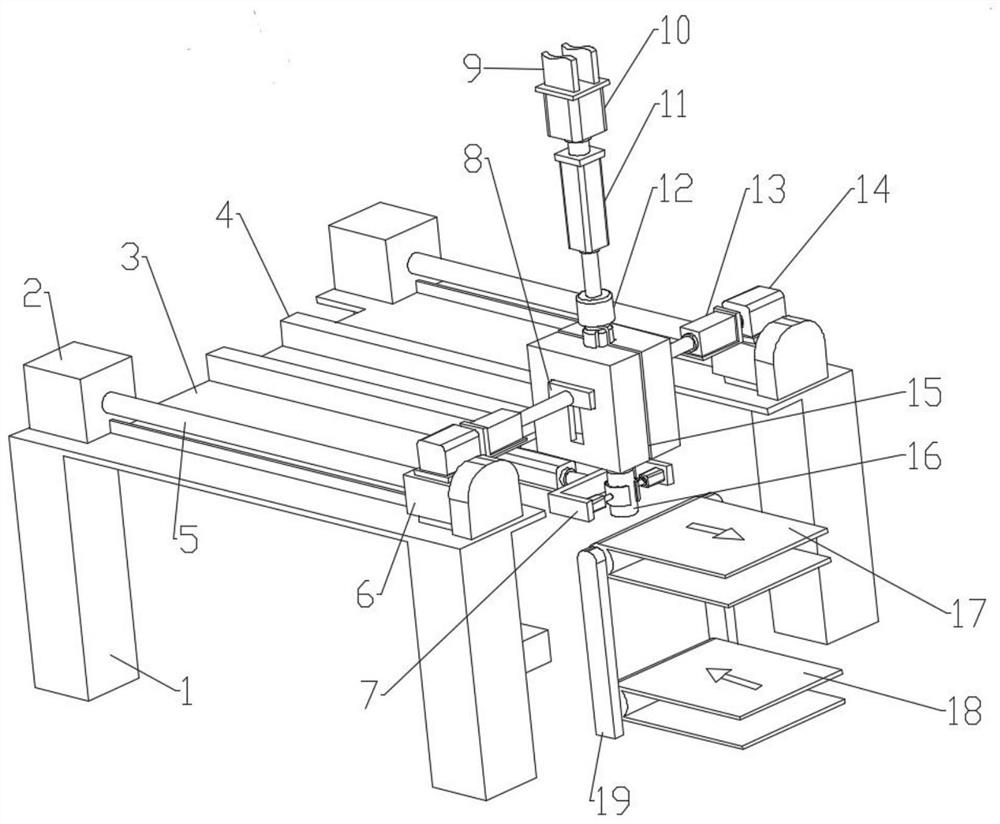

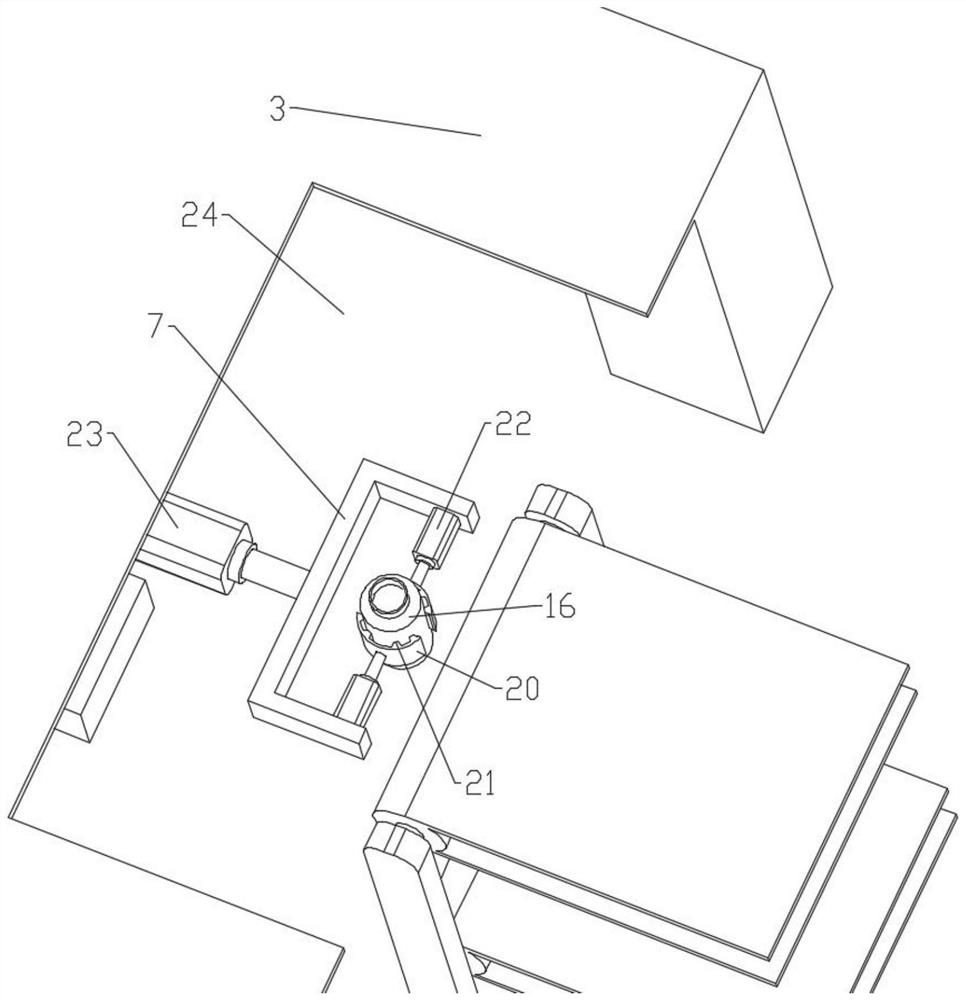

[0035] The pressing seat assembly assembly device automatically produced by the flusher includes a support table 3 supported by a first support column 1, a pressing seat clamp is movably arranged on the support table 3, and a first tubular linear motor 2 is symmetrically arranged on the support table 3 Drive the pressing seat fixture to translate, a liftable bottle body fixture is arranged under the support table 3, and the bottle body fixture is driven by the vertically arranged second tubular linear motor to move up and down, and the rear end of the support table 3 is provided with a feeding conveyor belt 18 and the discharge conveyor belt 17, characterized in that the discharge conveyor belt 17 is located above the feed conveyor belt 18 and both are supported by the second support column 19; The fixture 15 is supported by the support block 4 on the support table 3, and the clamping fixture 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com