Linear electric motor driven numerical control machine functional module

A linear motor and functional module technology, which is applied in driving devices, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of large mechanical inertia, large mechanical assembly, and low dynamic performance, and achieve small mechanical inertia and high rigidity. , the effect of good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

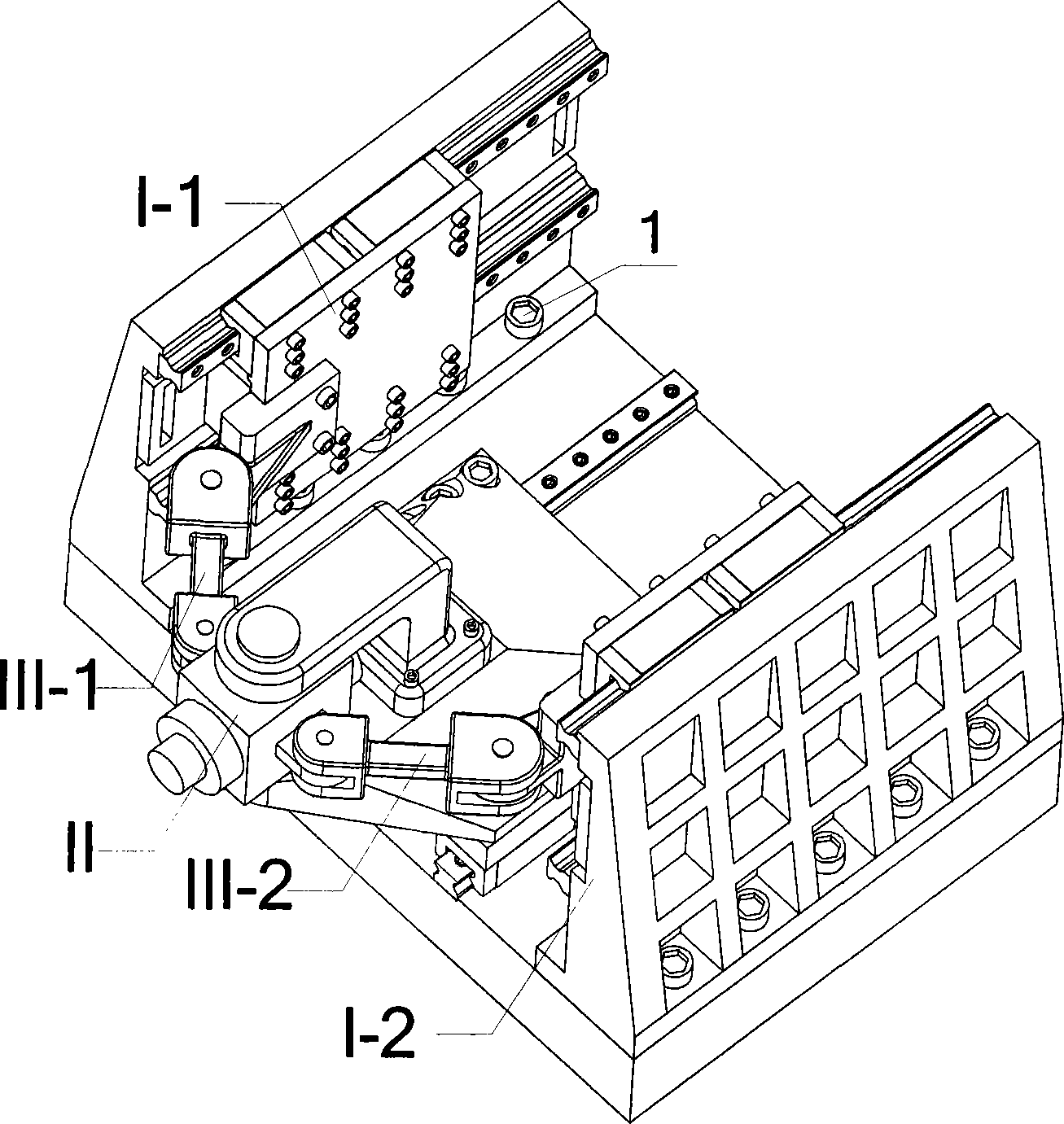

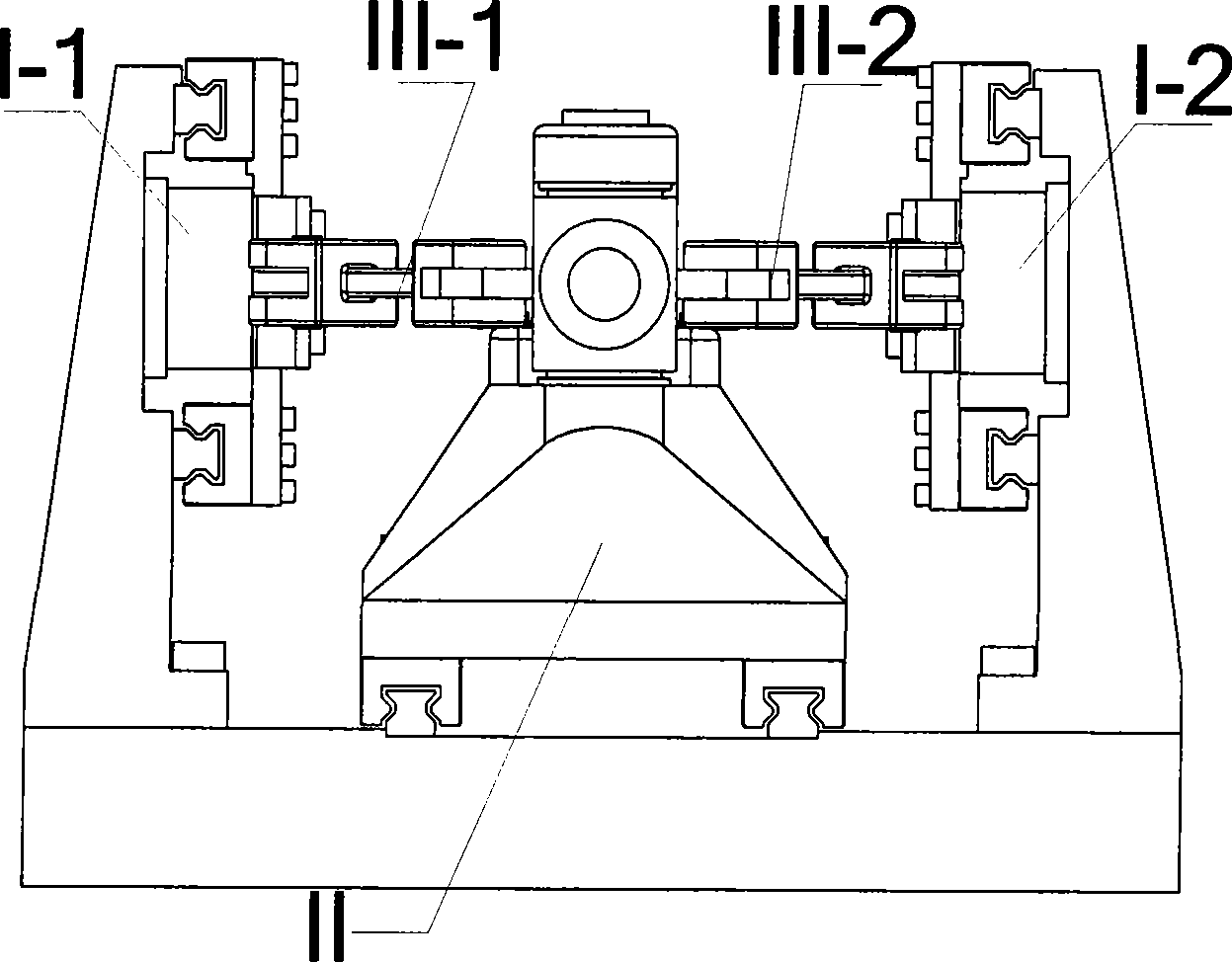

[0050] The linear motor-driven CNC machine tool functional modules include two sets of linear drive modules I-1, I-2, one tool platform movement module II, and two sets of connecting rod components III-1, III-2. The linear motions of the two linear drive modules I-1 and I-2 are the motion input of the present invention, and the tool platform 16 in the tool platform motion module II has two degrees of freedom, one linear motion and one rotary motion, which are the motions of the present invention output. It is characterized by:

[0051] Such as figure 1 , figure 2 , Figure 4 As shown, the functional module of the CNC machine tool driven by the linear motor is a symmetrical structure, which is symmetrical about the linear motion axis of the tool platform 16; the linear drive modules I-1 and I-2 are respectively arranged on the sides of the tool platform motion module II. Both sides are respectively connected with the tool platform motion module II through connecting rod co...

Embodiment 2

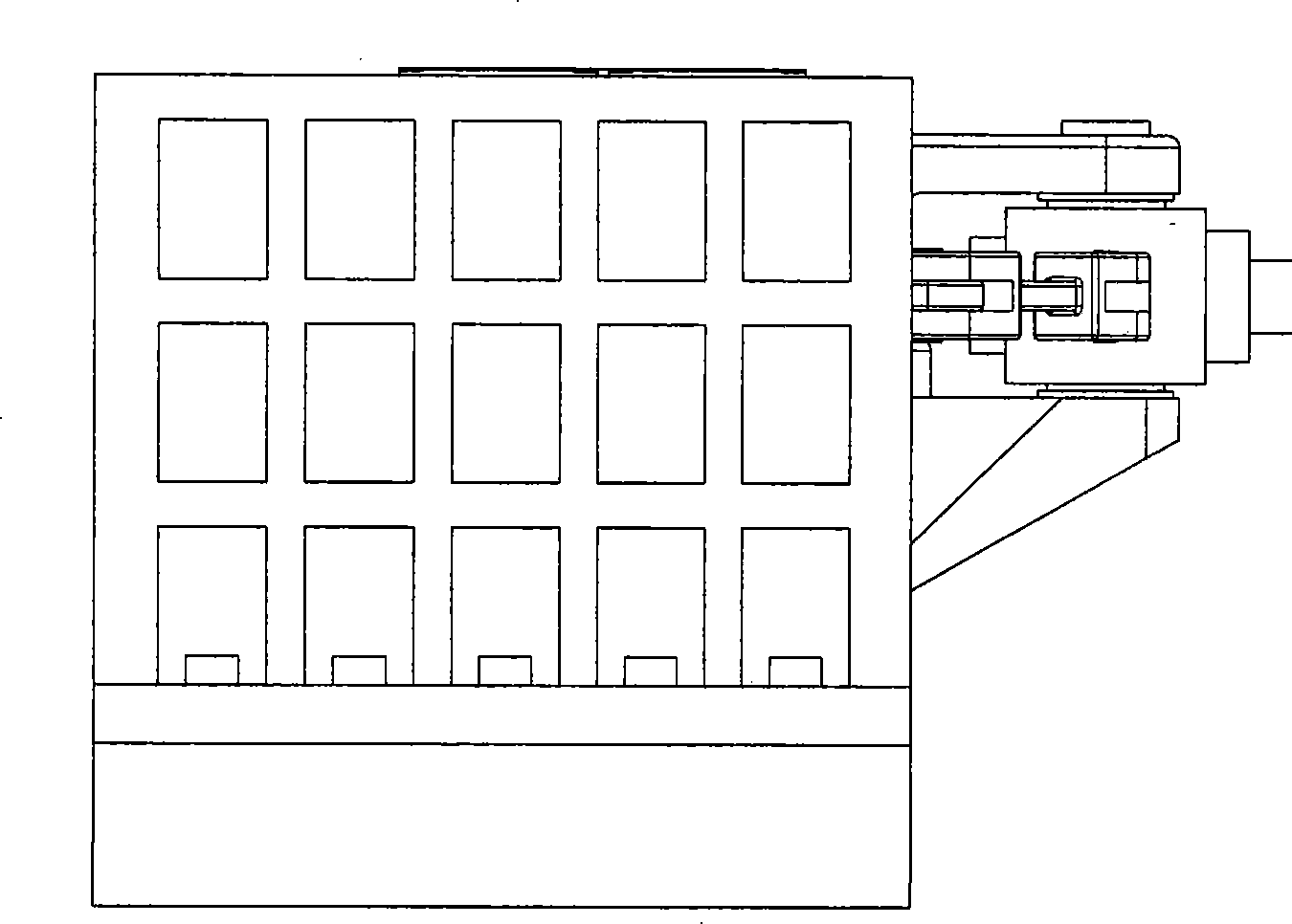

[0059] Embodiment 2 of the present invention is similar to Embodiment 1, including two sets of linear drive modules I-1', I-2', one tool platform movement module II', two sets of connecting rod components III-1', III-2 '. The two linear drive modules I-1', I-2' and the two groups of connecting rod parts III-1', III-2' are the same as those in the first embodiment. The difference is the implementation of the tool platform motion module II'.

[0060] Such as Figure 9 , Figure 10 , Figure 11 As shown, the tool platform movement module II' is composed of U-shaped seat 29, top cover 30, platform connecting rod 31, platform slider B 32, platform guide rail B 33, tool platform B 36, etc., the tool platform movement module II' is a vertically symmetrical structure. The U-shaped seat 29 is a combination of the motor seat 2 and the base 9 in the first embodiment into one part to complete the installation of the stator of the linear motor and the installation of the platform guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com