Oil production system of reciprocating submersible electric pump driven by sand-proof linear motor

A technology of linear motor and submersible electric pump, which is applied to machines/engines, pumps with flexible working elements, pumps, etc., can solve problems such as damage to linear motors, failure to work normally, and shortening of the service life of linear motors, so as to prolong the service life. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

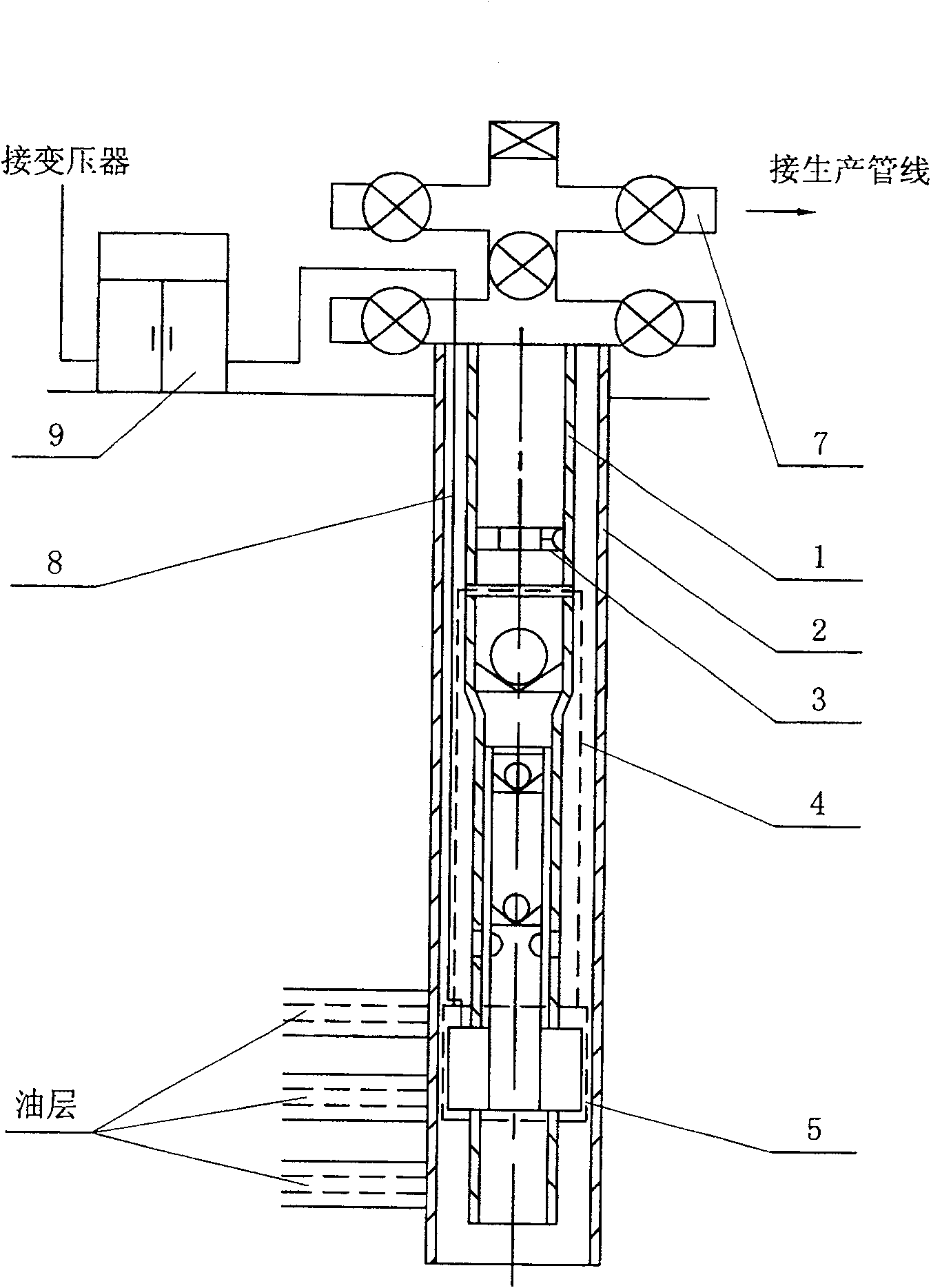

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment is made up of tubing 1, casing 2, reciprocating plunger pump 4, linear motor 5, drainer 3, wellhead 7, cable 8 and frequency conversion speed regulation control device 9; Wellhead 7 is fixed on The upper end of the casing 2, the oil pipe 1 is arranged in the casing 2, the upper end of the oil pipe 1 is fixedly connected with the lower end of the wellhead 7, and the oil drain 3 is installed in the oil pipe 1; the outlet end of the reciprocating plunger pump 4 is connected with the oil pipe 1 is fixedly connected to the lower end, the lower end of the reciprocating plunger pump 4 is fixedly connected to the upper end of the linear motor 5, one end of the cable 8 is connected to the terminal of the linear motor 5, and the other end of the cable 8 is connected to the frequency conversion speed control device 9 Connection; the reciprocating plunger pump 4 is a reciprocati...

specific Embodiment approach 2

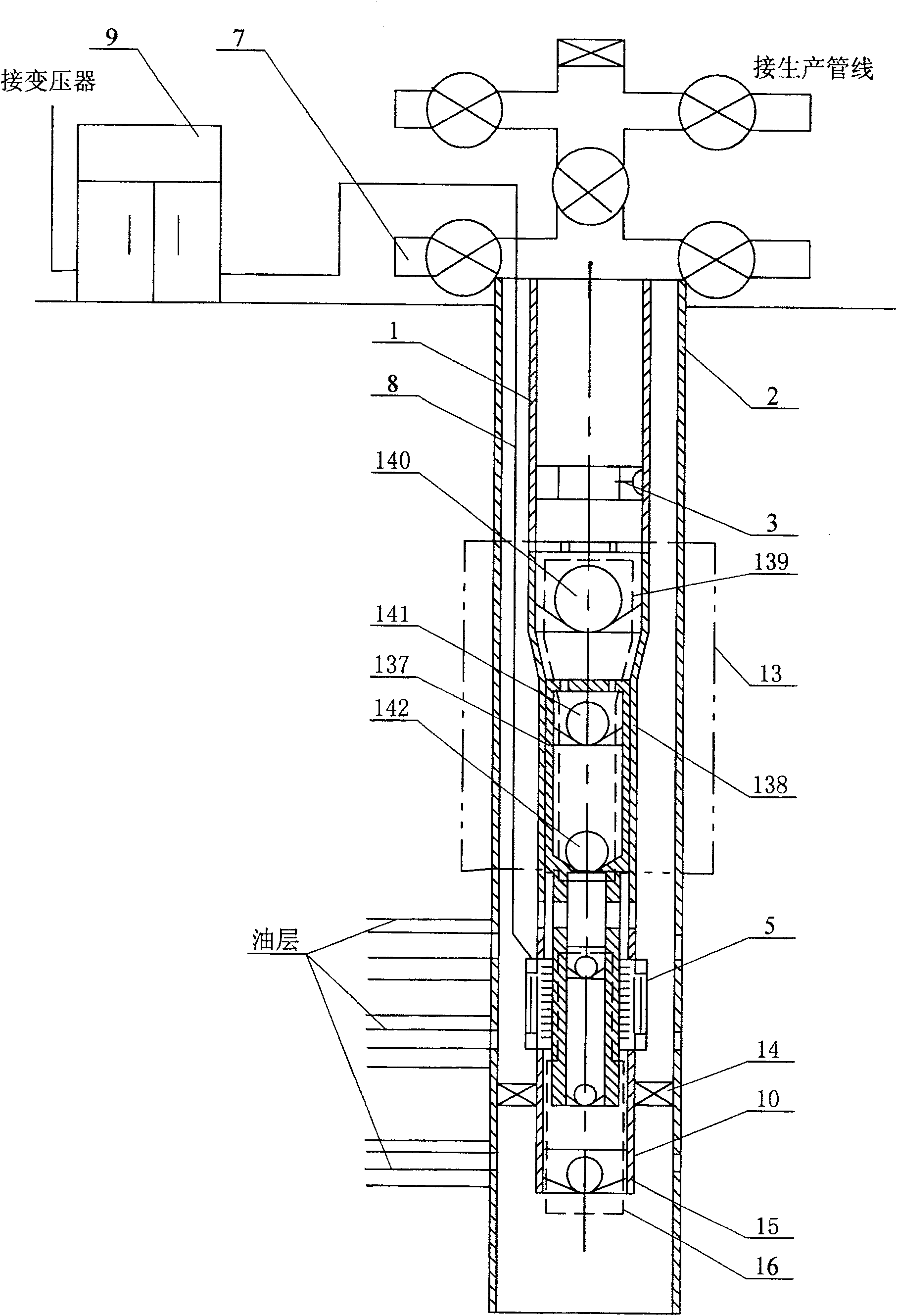

[0008] Specific implementation mode two: combination figure 1 , figure 2 and Figure 12 Describe this embodiment, the reciprocating plunger pump 4 of this embodiment is a reciprocating layered combined production plunger pump 10, and the reciprocating layered combined production plunger pump 10 is composed of the first upper oil well pump 13, the first The packer 14, the lower oil pipe 15 and the lower oil well pump 16 are composed; the lower end of the oil pipe 1 is fixedly connected with the upper end of the first upper oil well pump 13, and the lower end of the first upper oil well pump 13 is fixedly connected with the upper end of the linear motor 5 , the lower oil pipe 15 is located at the lower end of the linear motor 5, the upper end of the lower oil pipe 15 is fixedly connected with the linear motor 5, the outer wall of the lower oil pipe 15 is fixedly equipped with a first packer 14, and the lower oil well pump 16 is connected to the linear motor 5. Made into one; ...

specific Embodiment approach 3

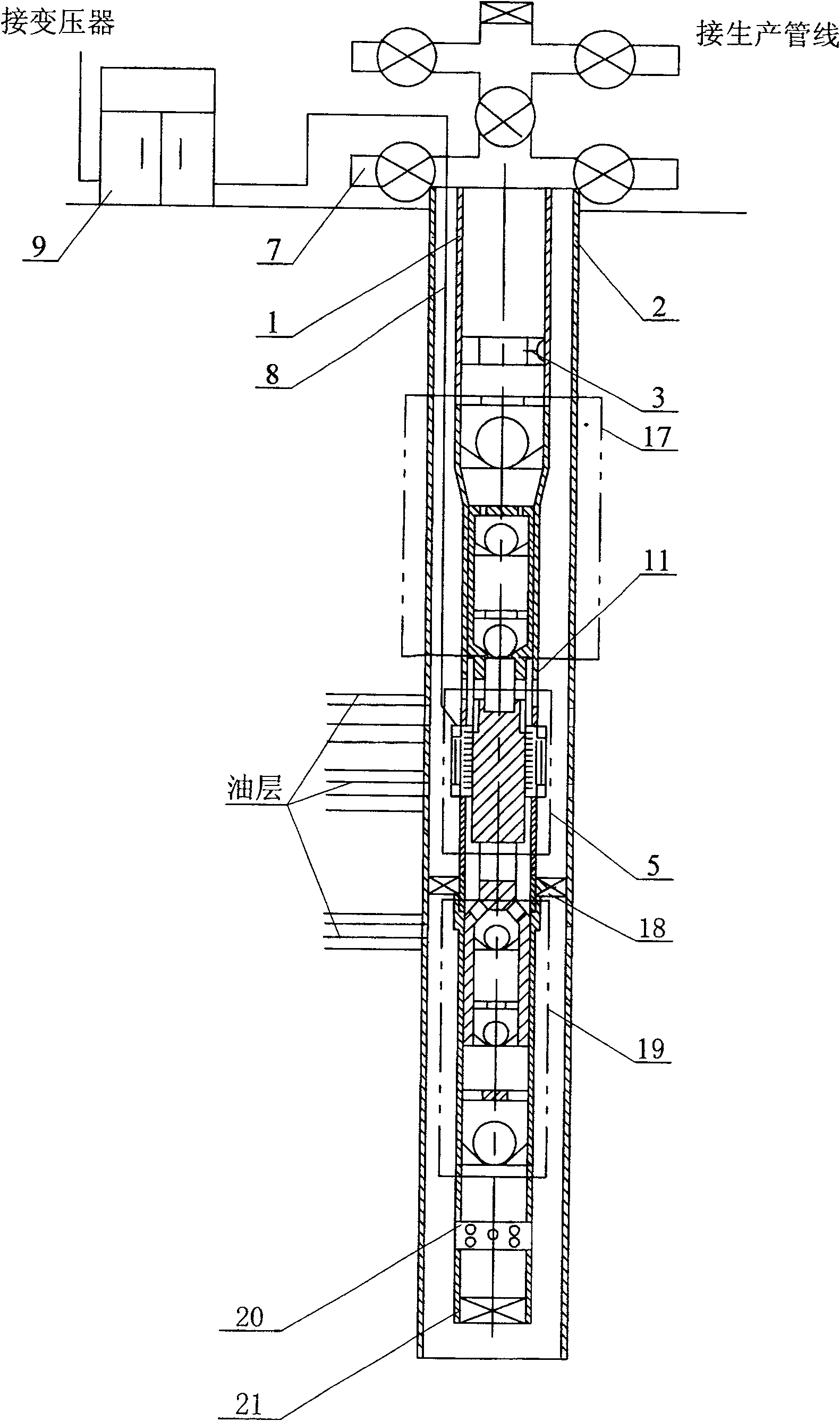

[0010] Specific implementation mode three: combination figure 1 and image 3 Describe this embodiment, the reciprocating plunger pump 4 of this embodiment is a reciprocating layered combined production double-suction plunger pump 11, and the reciprocating layered combined production double-suction plunger pump 11 is controlled by the second upper oil well pump 17. The second packer 18, the second lower oil pump 19, the screen pipe 20 and the plug 21; the lower end of the oil pipe 1 is fixedly connected with the upper end of the second upper oil pump 17, and the lower end of the second upper oil pump 17 is connected with The upper end of the linear motor 5 is fixedly connected, the lower end of the linear motor 5 is fixedly connected to the upper end of the second lower oil well pump 19, and the second packer 18 is fixedly installed between the linear motor 5 and the second lower oil well pump 19. In the inner cavity of the casing pipe 2 , the lower end of the second lower oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com