A tower-type solar closed pressure heat absorption system and method

A solar closed-type and tower-type technology, applied in the field of heat-absorbing systems, can solve the problems of increased equipment costs, poor safety, increased system investment and operating costs, etc., achieve low investment costs and operating costs, and improve stability and safety , The effect of reducing system power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

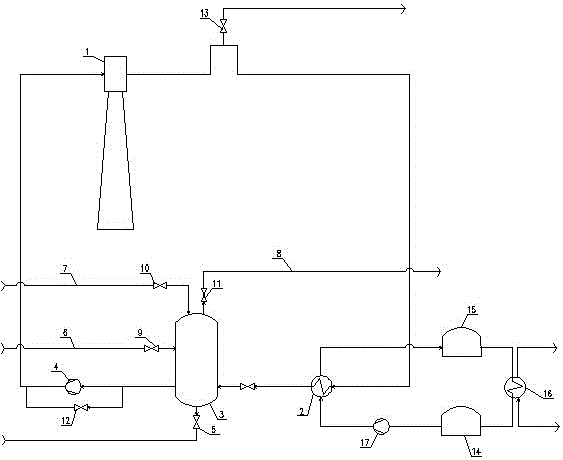

[0016] Such as figure 1 As shown, the tower-type solar closed-type pressure heat absorption system includes a heat absorber 1 located at a high position, a heat exchanger 2 located at a low partition wall, a storage buffer tank 3 and a circulation pump 4, and the outlet of the heat absorber 1 is connected to the The inlet of the heat exchanger 2 is connected by a pipeline, the lower end of the storage buffer tank 3 is connected with a discharge pipe, the discharge pipe is provided with a discharge valve 5, and the storage buffer tank 3 is connected with a heat-absorbing medium adding pipe 6, On the storage buffer tank 3 which is higher than the heat-absorbing medium adding pipe 6, an air intake pipe 7 and an exhaust pipe 8 are also connected, and a valve 10 or Valve 11 and valve 9, one side of the storage buffer tank 3 is connected to the outlet of the heat exchanger 2 through a pipeline, and the other side of the storage buffer tank 3 is connected to the inlet of the circulat...

Embodiment 2

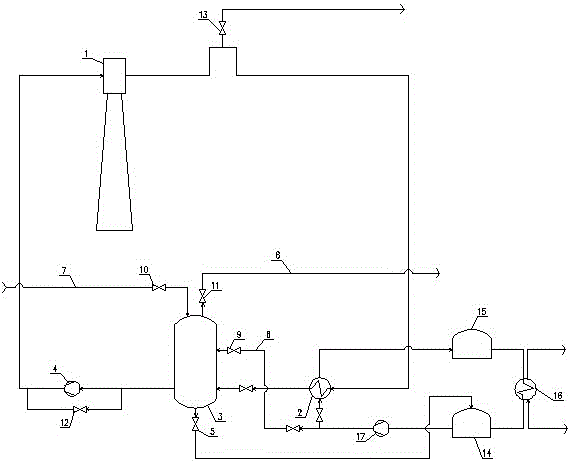

[0020] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the heat-absorbing medium feeding pipe 6 is connected to the outlet of the heat storage medium circulation pump 17, and the discharge pipe is connected to the low-temperature storage tank 14; this embodiment is suitable for absorbing When the heat medium and heat storage medium are the same medium, the medium in the low-temperature storage tank 14 is filled into the storage buffer tank 3 when starting; when emptying, the medium is discharged into the low-temperature storage tank 14; the system structure can be simplified fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com