Totally closed downhole pressure gauge

A downhole pressure and fully enclosed technology, applied in the field of pressure gauges, can solve problems such as poor sealing of pressure gauges, and achieve the effect of ensuring the isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

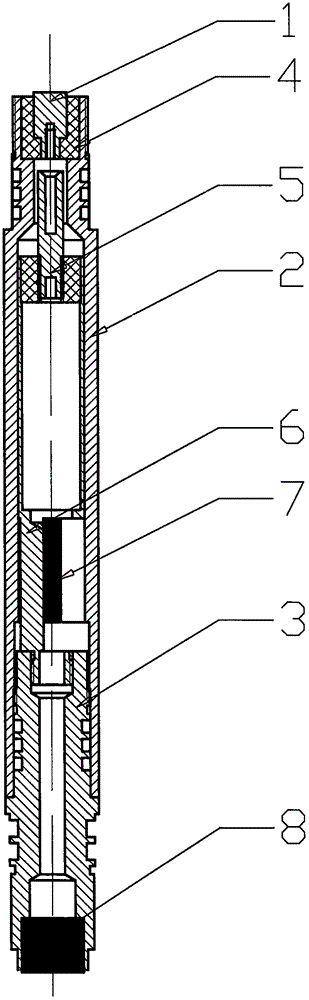

[0010] As shown in the drawings, the fully enclosed downhole pressure gauge includes a welding electrode 1 , a welding sleeve 2 , and a sensor welding bracket 3 . The welding insulating ring 4 is welded and connected to each other between the welding electrode 1 and the welding sleeve 2, and all connections between the inner cavity of the instrument and the outside are welded. There is a circuit support 6 in the welding sleeve 2, and the upper end of the circuit support 6 is connected to the welding electrode 1 through the rotating connector 5. There is a posture detection circuit 7 and a battery in the circuit support 6. There is a memory and a temperature sensor core on the posture detection circuit 7. The temperature signal is collected and stored, and the instrument uses the attitude detection circuit 7 to detect the working state of the instrument attitude control inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com