Primary wind speed leveling and automatic measuring device

An automatic measurement and wind speed technology, which is applied in the direction of measuring device, fluid velocity measurement, velocity/acceleration/shock measurement, etc., can solve the problems of intercom communication failure, high noise, heavy workload of measuring personnel, etc., and achieve real-time adjustment and reduce The effect of working intensity and avoiding human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

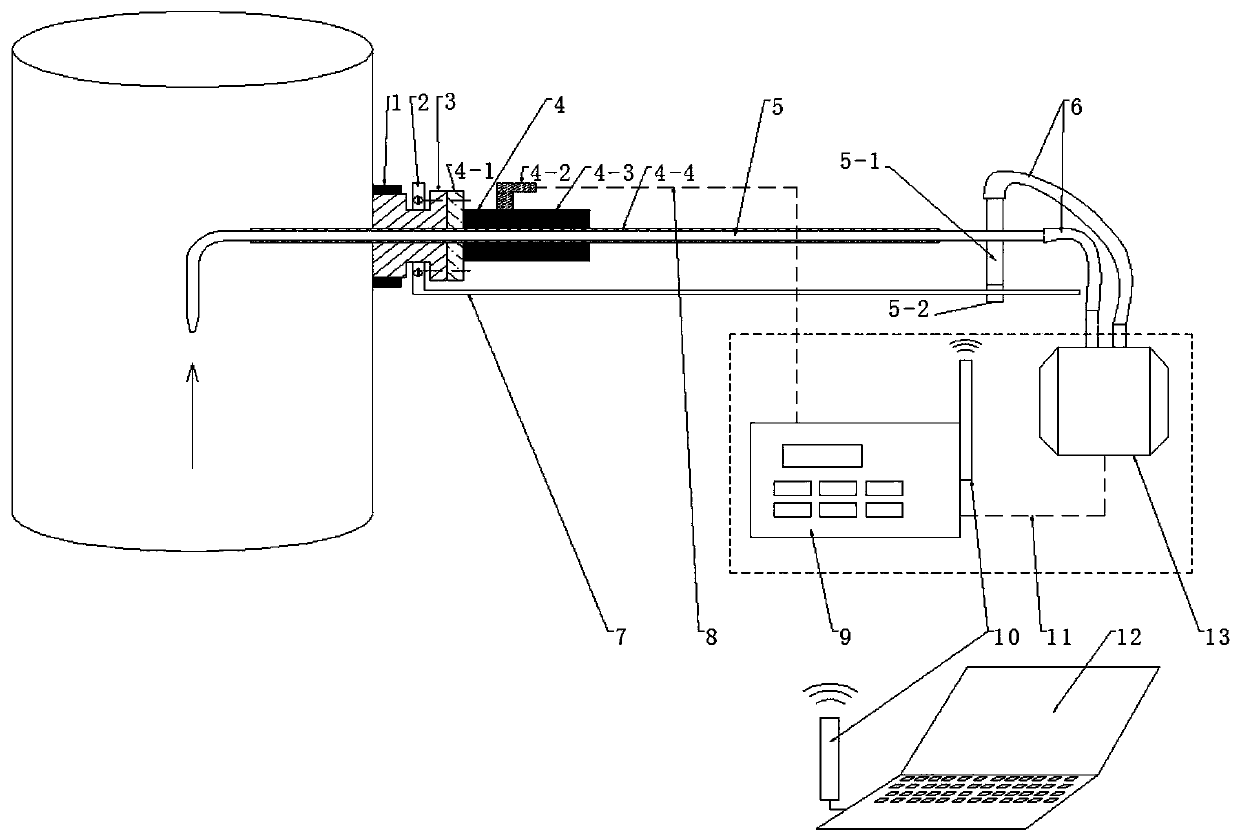

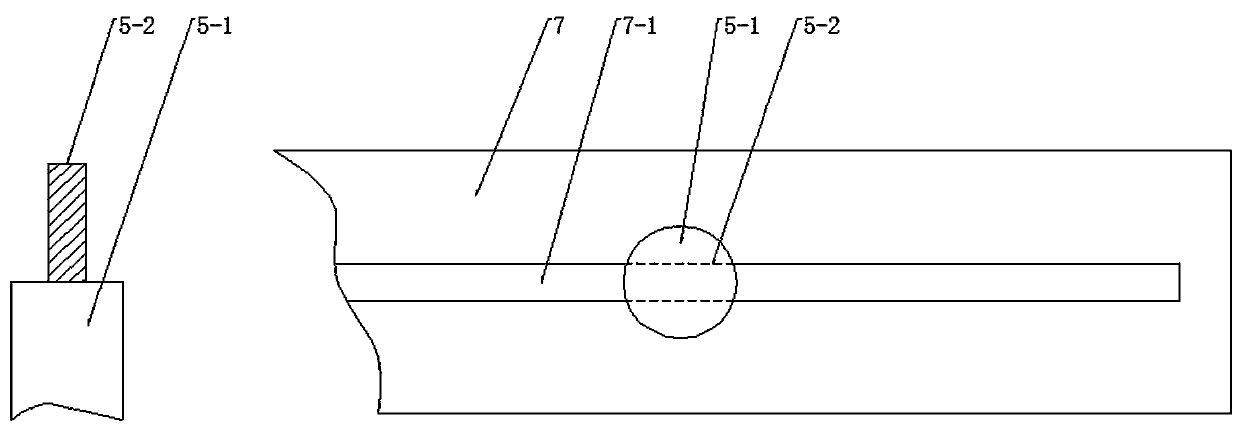

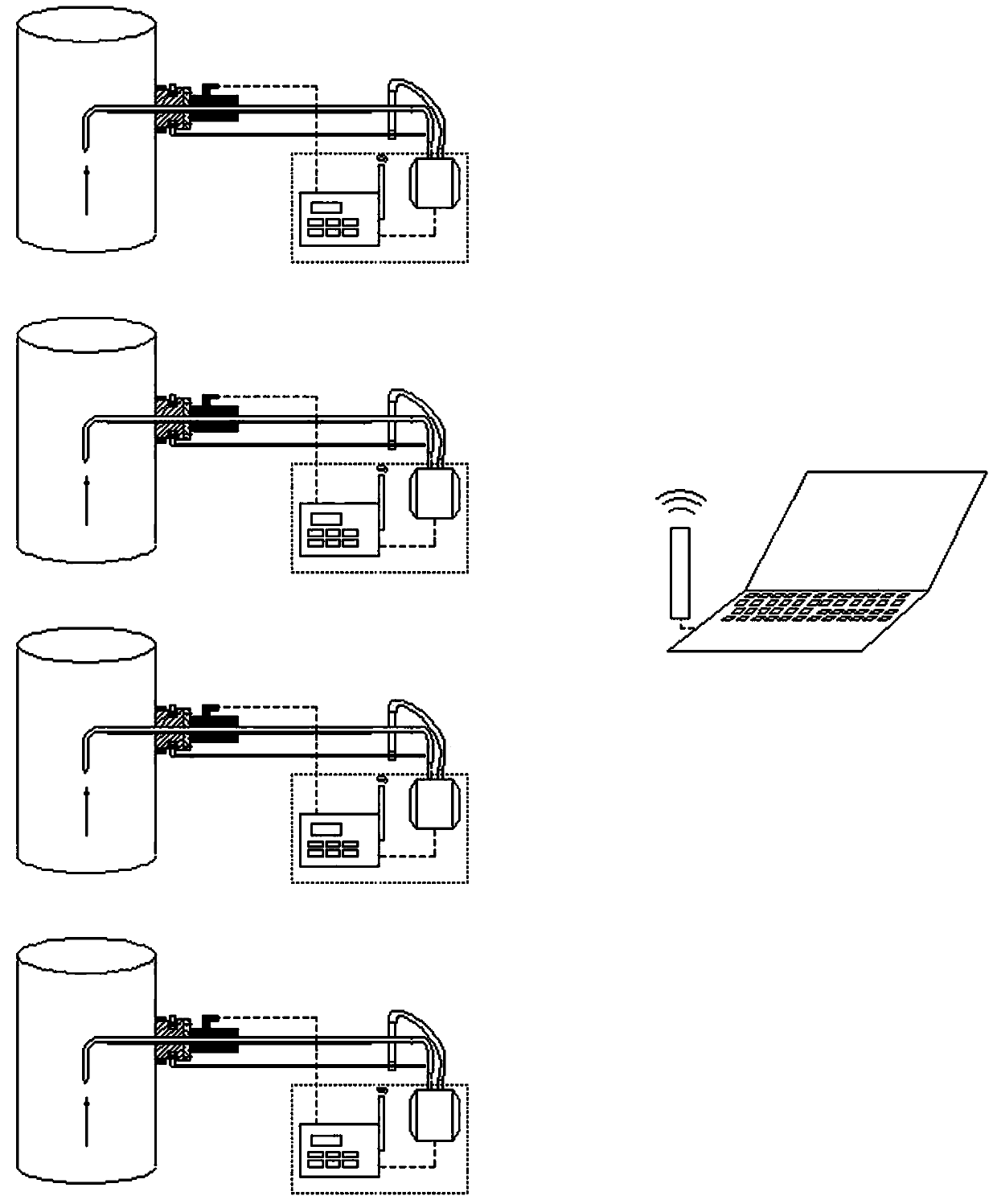

[0024] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

[0025] as attached figure 1 As shown, a primary wind speed leveling automatic measuring device includes: a flue, one side of which is provided with a measuring hole 1; a pitot tube 5, the measuring end of the pitot tube 5 extends into the flue to be measured through the measuring hole 1, The other end is located outside the flue to be tested; the tubular linear motor 4 is fixed on the flue through the motor connection flange 4-1, and the motor stator 4-3 is arranged coaxially inside, and the pitot tube 5 is coaxially inserted into the motor stator 4- In the inner hole of the motor slide bar 4-4 in 3, the pitot tube 5 is connected and fixed with the motor slide bar 4-4, and the tubular linear motor 4 drives the pitot tube 5 measuring end to move horizontally in the flue; the automatic controller 9, the tube The motor driver 4-2 on the type linear motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com