Flat linear motor

A linear motor and flat technology, applied in the field of flat linear motors, can solve the problems of high difficulty in processing and assembly, complex structure, large overall size of the motor, etc., and achieve the effects of reducing production costs, simplifying the overall structure, and simplifying the motor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

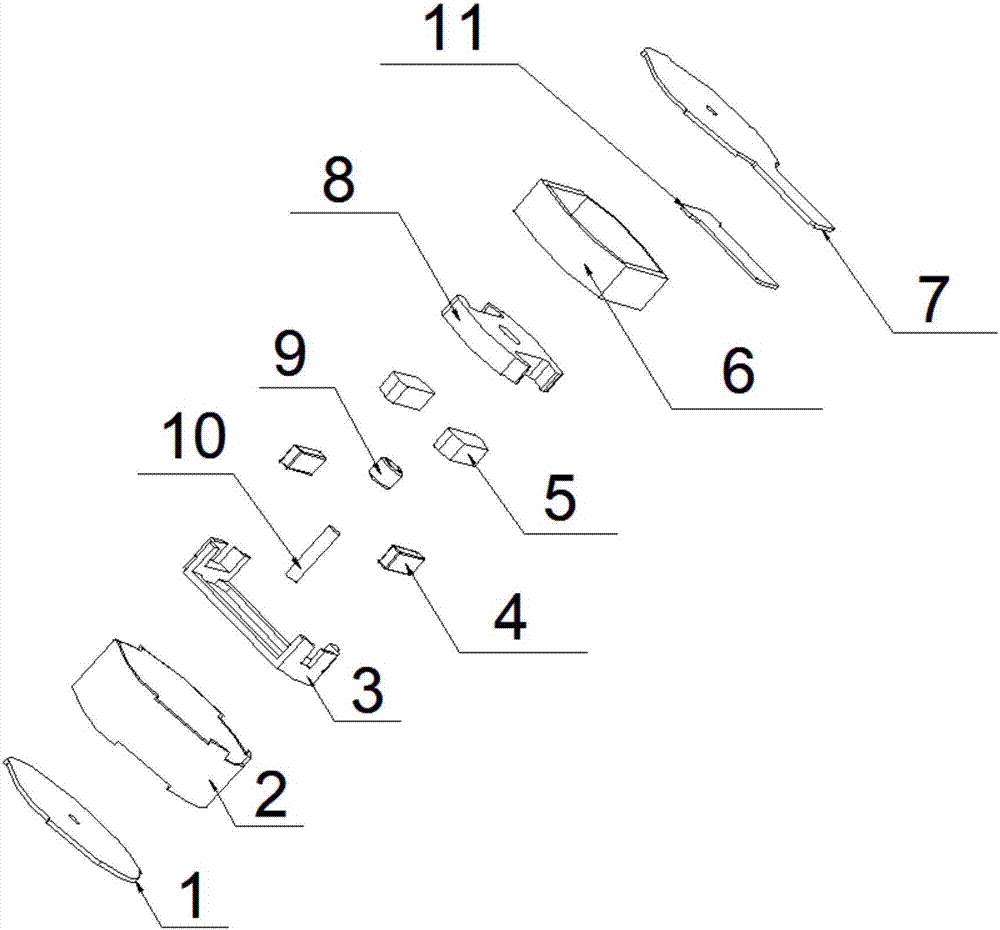

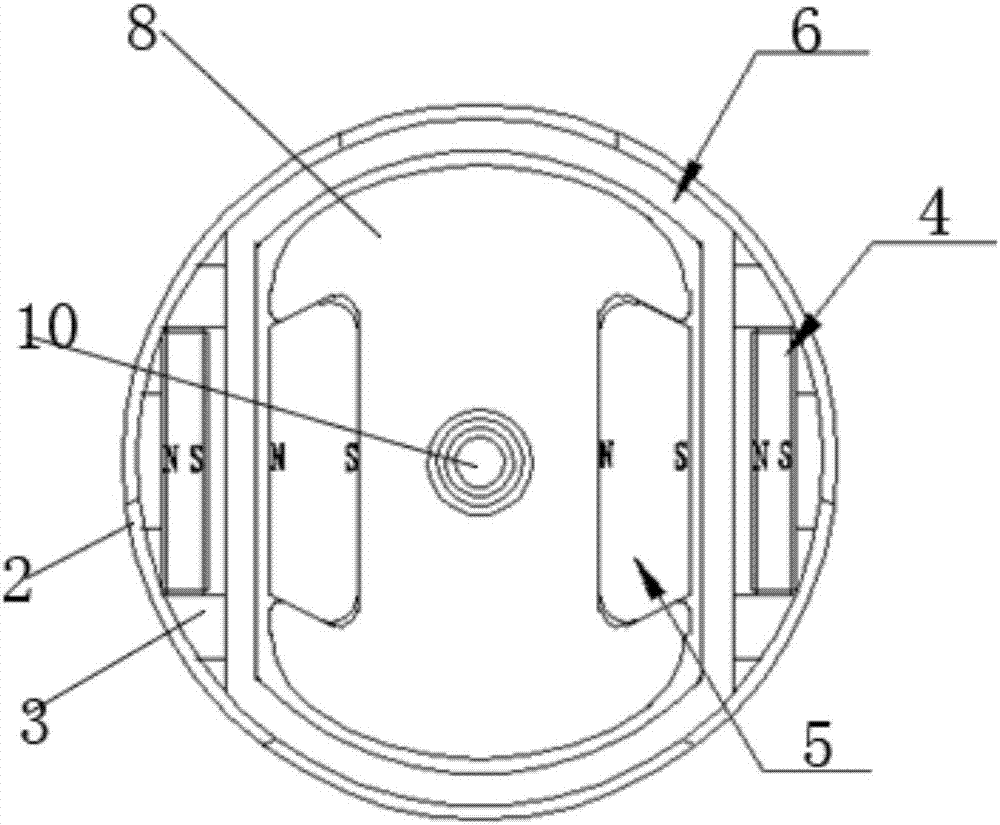

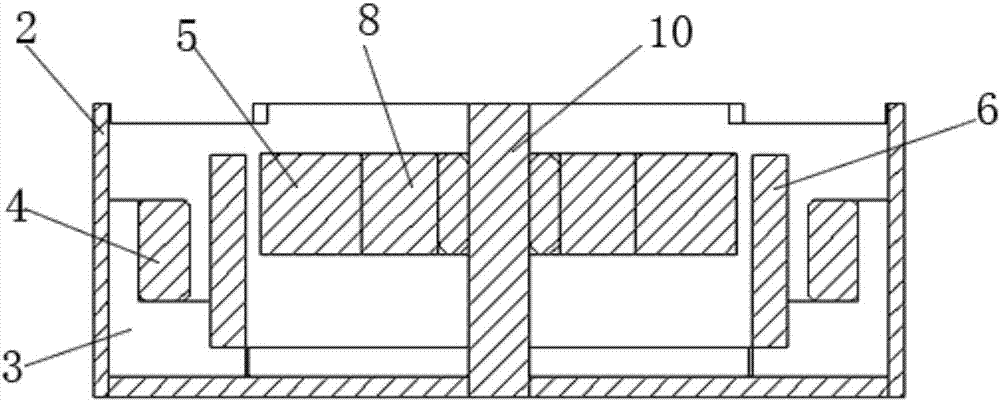

[0047] refer to Figure 1-4 , a flat linear motor of the present invention, including a housing, the housing is provided with a stator 02, a mover 01 and a single shaft 10, the single shaft 10 is installed in the center of the mover, the stator includes a driving coil 6, and the driving coil is wound The mover is set in one circle; there are at least two pairs of magnets between the stator 02 and the mover 01; each pair of magnets includes a driving positioning magnet 5 and a positioning magnet 4, and the driving positioning magnet 5 is set on the moving element, and the driving positioning magnet 5 is opposite to the positioning magnet 4, and the position of the positioning magnet 4 is fixed relative to the shell.

[0048] When the linear motor is working, the driving coil 6 is energized and generates an electromagnetic field, and the mover including the driving positioning magnet 5 is located in the electromagnetic field, and the driving positioning magnet 5 is pushed by the...

Embodiment 2

[0067] refer to Figure 5 , this embodiment is a modification made on the basis of embodiment 1, the details are as follows.

[0068] In this embodiment, the flat linear motor is flat and square as a whole, and the housing is also square.

[0069] In this embodiment, four driving and positioning magnets 5 are included, and the four driving and positioning magnets 5 are evenly distributed around the outer ring of the copper 8; further, the four driving and positioning magnets 5 form a ring structure, and the ring structure is directly sleeved on the On the outer ring of copper 8. The fixing method of the magnet has a simple structure and is convenient for installation.

[0070] In this embodiment, four positioning magnets 4 are correspondingly arranged; since the housing is square, in order to adapt to the shape of the housing, this embodiment directly arranges four positioning magnets 4 on the four corners of the housing, and Drive positioning magnet 5 relative.

[0071] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com