Sample transfer device

A push device and sample transfer technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of unfavorable work efficiency, improved workpiece saving, limited advancing distance, workpiece fatigue, etc., to achieve automatic and rapid setting of advancing, improving efficiency and saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

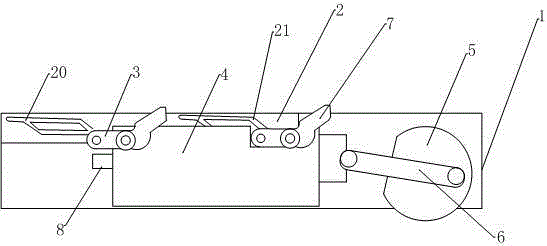

[0019] Such as figure 1 As shown, the sample transfer pushing device includes a mounting bracket 1, a plastic mounting plate A2 is provided above the mounting bracket 1, a linear guide rail 8 is provided below the mounting plate A2, and a linear guide rail 8 that can move back and forth in the horizontal direction is arranged on the linear guide rail 8. The mounting plate B4 made of stainless steel, the left end of the mounting plate B4 is hinged with the spring push block A3, the right end of the mounting plate B4 is hinged with the spring push block B7, and the mounting plate A2 corresponds to the spring push block A3 and the spring push block B7 respectively. The positions are respectively provided with the push route groove A20 and the push route groove B21 for the bullet push block A3 and the spring push block B7 to pass through. Both the push route groove A20 and the push route groove B21 are parallelogram grooves extending from the upper and lower sides. The right side ...

Embodiment 2

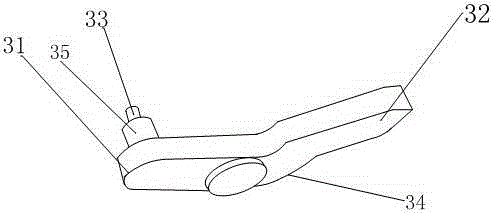

[0022] Such as figure 1 and figure 2 As shown, similar to embodiment 1, the difference is:

[0023] The elastic push block A3 or the elastic push block B7 includes a sliding plate with a hole, one end of the sliding plate is a U-shaped end 31, and the other end is an inclined end 32 connected with the U-shaped end 31 by an arc section 34, and the arc section 34 The angle is 30-75°, and the setting of the arc section 34 is beneficial to the reciprocating motion of the spring push block A3 and the spring push block B7, and the U-shaped end 31 is also connected with a contact end responsible for sliding in the push route groove A20 or the push route groove B21 33. The cylindrical shape of the contact end 33 facilitates its sliding in the groove. The structure of the spring pushing block A3 and the spring pushing block B7 is conducive to their reciprocating movement driven by the mounting plate B4.

[0024] The width of the pushing path groove A20 matches the end of the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com