Magnetic check valve for range hood and bath heater

A range hood and check valve technology, applied in the direction of lift valve, control valve, valve device, etc., can solve the problems of slow exhaust, poor flue blocking effect, and easy failure of mechanical structure, so as to achieve easy sealing and increase Stability, the effect of avoiding mechanical fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

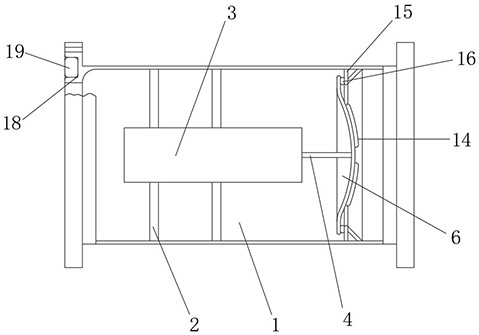

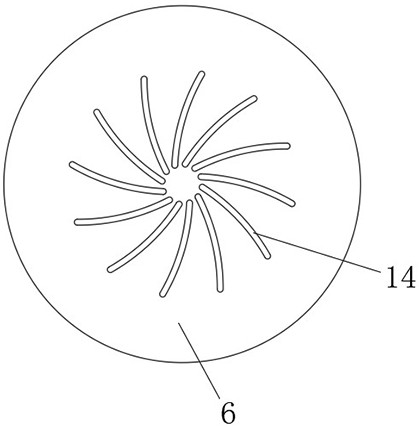

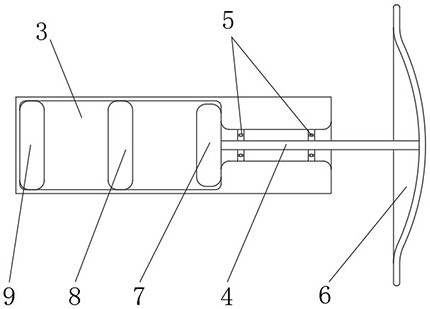

[0025] see figure 1 , figure 2 , image 3 , the present invention provides a technical solution: a magnetic check valve for range hoods and Yuba, including a connecting pipe 1, a reset sleeve 3 installed inside the connecting pipe 1, and fixed between the connecting pipe 1 and the reset sleeve 3 The support frame 2, the inside of one end of the reset sleeve 3 is equipped with a linear bearing 5, the inner movable sleeve of the linear bearing 5 is connected with a telescopic rod 4, and the end of the telescopic rod 4 located outside the reset sleeve 3 is fixed with a baffle 6. 4 One end located inside the reset sleeve 3 is fixed with a buffer assembly, the outer surface of the baffle plate 6 is welded with a deflection rib 14, the inner surface of the connecting pipe 1 is welded with a support ring 15, and a Airtight components.

[0026] In this embodiment, through the flexible installation of the telescopic rod 4 in the linear bearing 5, one end of the telescopic rod 4 is ...

Embodiment 2

[0037] see figure 1 , figure 2 , Figure 4, the present invention provides a technical solution: a magnetic check valve for range hoods and Yuba, including a connecting pipe 1, a reset sleeve 3 installed inside the connecting pipe 1, and fixed between the connecting pipe 1 and the reset sleeve 3 The support frame 2, the inside of one end of the reset sleeve 3 is equipped with a linear bearing 5, the inner movable sleeve of the linear bearing 5 is connected with a telescopic rod 4, and the end of the telescopic rod 4 located outside the reset sleeve 3 is fixed with a baffle 6. 4 One end located inside the reset sleeve 3 is fixed with a buffer assembly, the outer surface of the baffle plate 6 is welded with a deflection rib 14, the inner surface of the connecting pipe 1 is welded with a support ring 15, and a Airtight components.

[0038] In this embodiment, through the flexible installation of the telescopic rod 4 in the linear bearing 5, one end of the telescopic rod 4 is ...

Embodiment 3

[0048] see figure 1 , The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the sealing component is a first sealant ring 16 , and the first sealant ring 16 is arranged between the support ring 15 and the baffle 6 .

[0049] In this embodiment, through the sealing assembly composed of the first sealant ring 16, and the first sealant ring 16 is arranged on the inner ring of the support ring 15, it is convenient to seal between the baffle plate 6 and the support ring 15, thereby increasing The sealing performance of the check valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com