Long-life acetylene generator stirring mechanism and method

A technology of acetylene generator and stirring mechanism, which is applied in the fields of acetylene generator, acetylene gas generator parts, petroleum industry, etc. It can solve the problems of increasing the service life of the stirring mechanism, breaking the rotating arm and clamp, frequent maintenance and replacement, etc. , to achieve the effect of reducing vertical failure stress, avoiding loosening and cracking, and preventing mechanical fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First of all, it needs to be explained that the working environment in this implementation is for the acetylene generator.

[0034] About the acetylene generator, it is a device that can make water and calcium carbide react chemically to generate acetylene gas under a certain pressure. It can produce acetylene by fully reacting water and calcium carbide in a closed space.

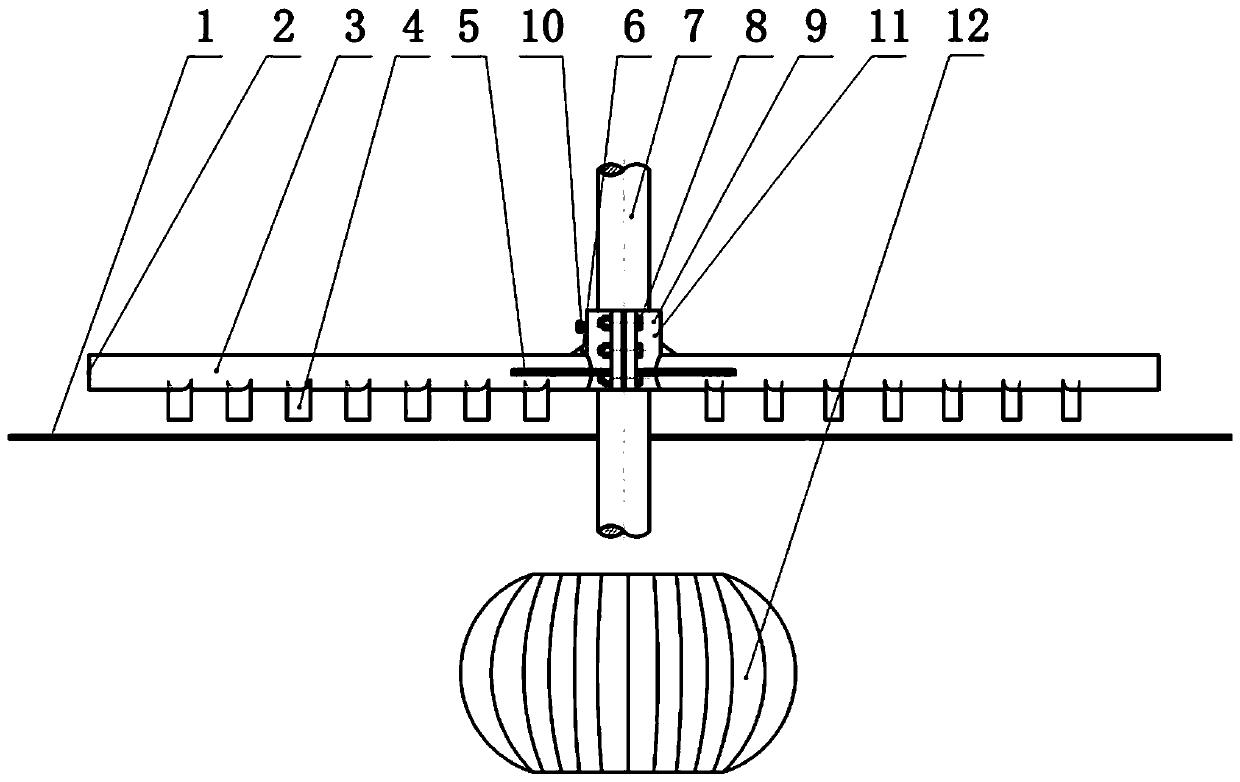

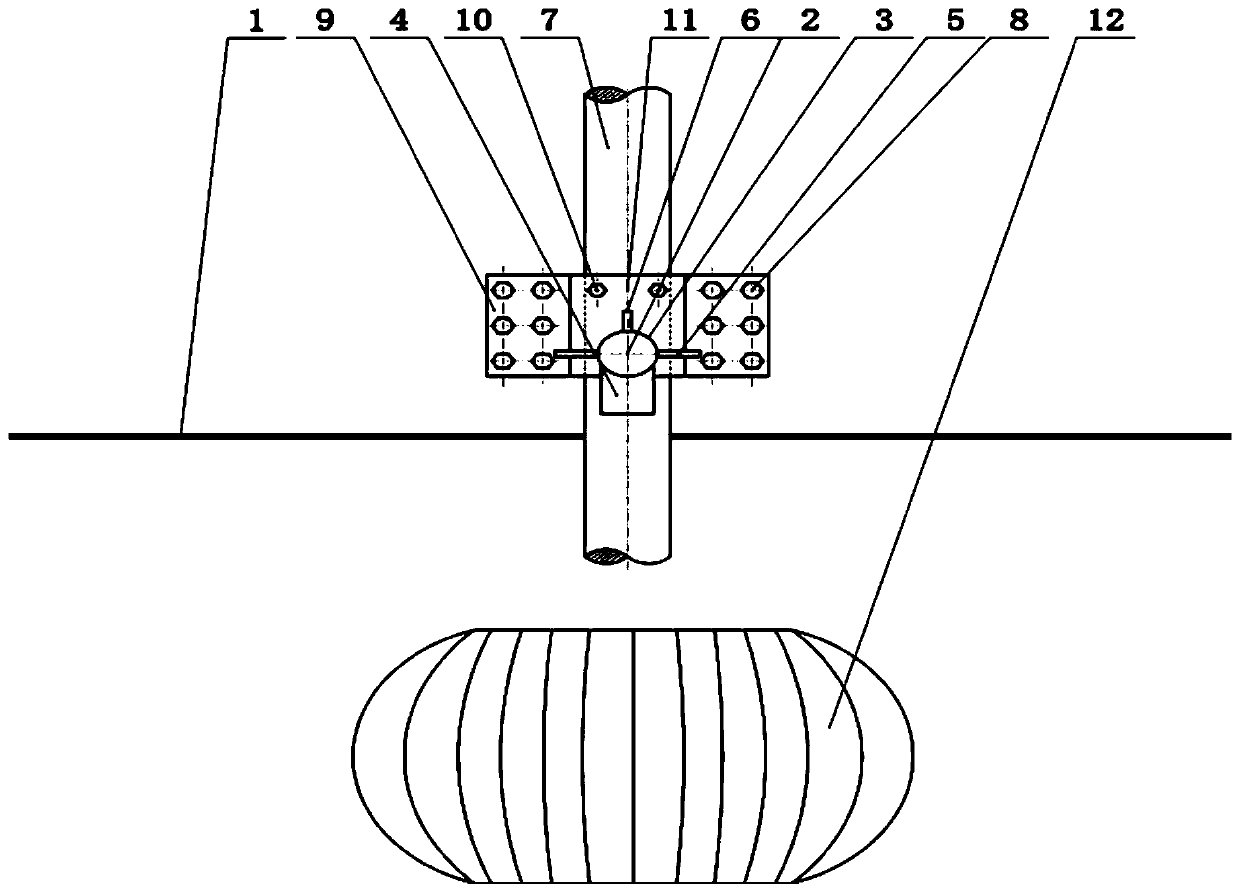

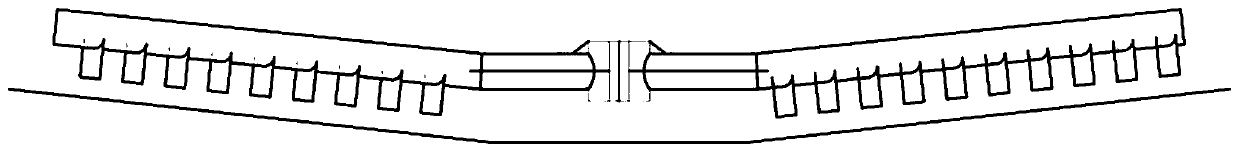

[0035] This embodiment discloses a stirring mechanism of a long-life acetylene generator, which includes a rotating shaft, a rotating arm, stirring teeth 4, a positioning mechanism and a baffle plate 1, the rotating shaft passes through the baffle plate 1, the rotating shaft is perpendicular to the rotating arm, and rotates The shaft is connected to the rotating arm through the positioning sub-mechanism, and the rotating arm is connected to a plurality of stirring teeth 4; the rotating arm has a hollow structure, and the rotating arm can isolate the hollow structure from the surrounding environment to...

Embodiment 2

[0056] Embodiment 2 discloses a long-life acetylene generator stirring mechanism and its working method, comprising the following steps:

[0057] Step 1: Assemble the stirring mechanism of the long-life acetylene generator as described in Example 1. First weld the stirring tooth 4 on the rotating arm, weld the rotating arm on the clamp 9, then weld the horizontal reinforcing plate 5 and the vertical reinforcing plate 6, weld the blocking plate 2 at the pipe end of the rotating arm to block the rotating arm, Then a pair of hoops 9 are installed on the stirring shaft 7 through 12 high-strength bolts 8, and finally high-strength screws 10 are installed.

[0058] Step 2: The power source 12 drives the stirring shaft 7 to rotate at a certain speed, and the stirring teeth 4 repeatedly stir the calcium carbide on the retaining plate, so that the reaction surface of the calcium carbide is continuously updated, fully contacted and reacted with water, and the residual calcium carbide is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com