Fuel gas pressure regulator capable of reducing fatigue damage

A gas pressure regulator, fatigue damage technology, applied in the direction of combustion engine, internal combustion piston engine, valve operation/release device, etc., can solve the problems of potential safety hazards in the pressure regulation system, different pressure reduction requirements, high procurement costs, etc., to achieve reduction Maintenance work intensity, reduce fatigue damage, good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

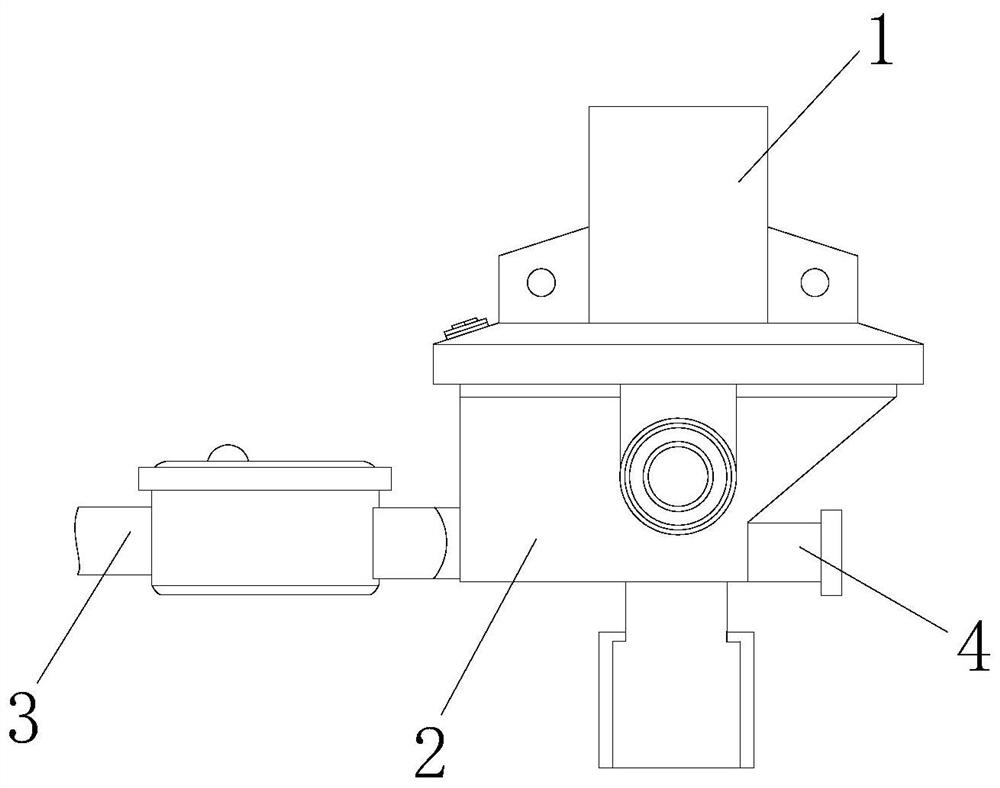

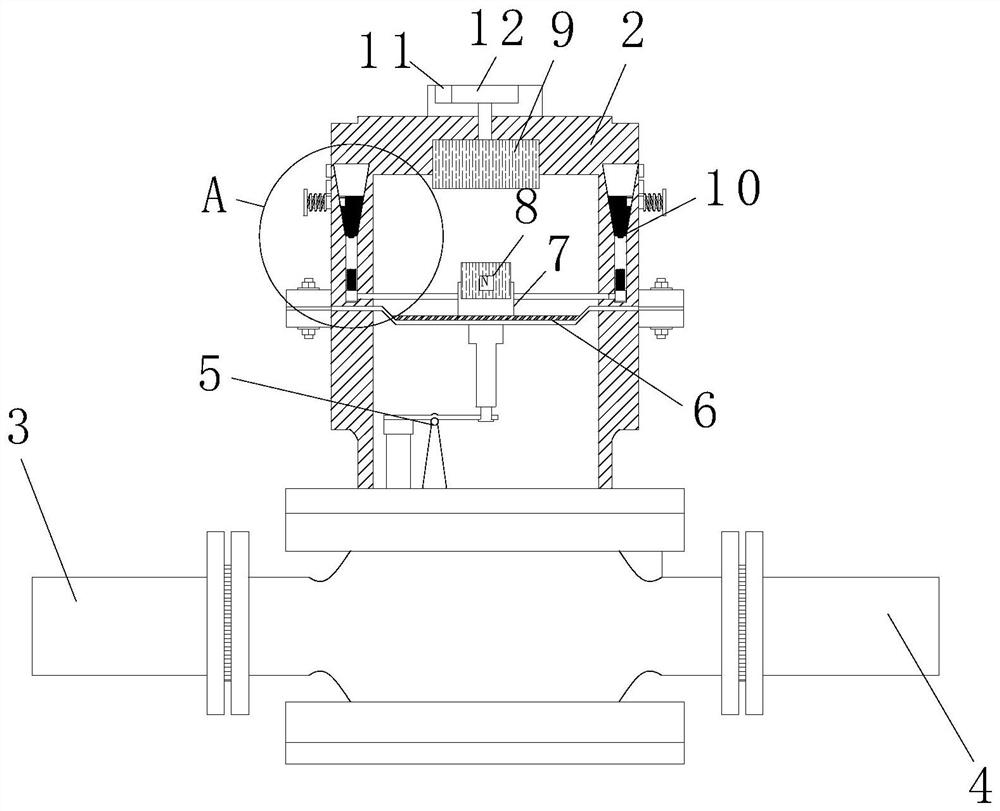

[0026] like Figure 1-3 As shown, a gas pressure regulator that can reduce fatigue damage includes a pressure regulating chamber 2, the pressure regulating chamber 2 is divided into an upper gas chamber and a lower gas chamber, and the middle position of the upper gas chamber and the lower gas chamber passes through the rubber membrane 6 Separated, the rubber film 6 is driven up and down by the lever assembly 5 located in the lower air chamber, the center position of the upper end of the rubber film 6 is provided with a base 7, and the upper end of the base 7 is provided with a permanent magnet 8;

[0027] In the prior art, the gas pressure regulator includes a valve body 1 and a pressure regulating chamber 2. The two ends of the pressure regulating chamber 2 are respectively provided with an air inlet 3 and an air outlet 4. During operation, high-pressure petroleum gas is flushed through the air inlet 3. The valve pad enters the lower air chamber. With the increase of the gas...

Embodiment 2

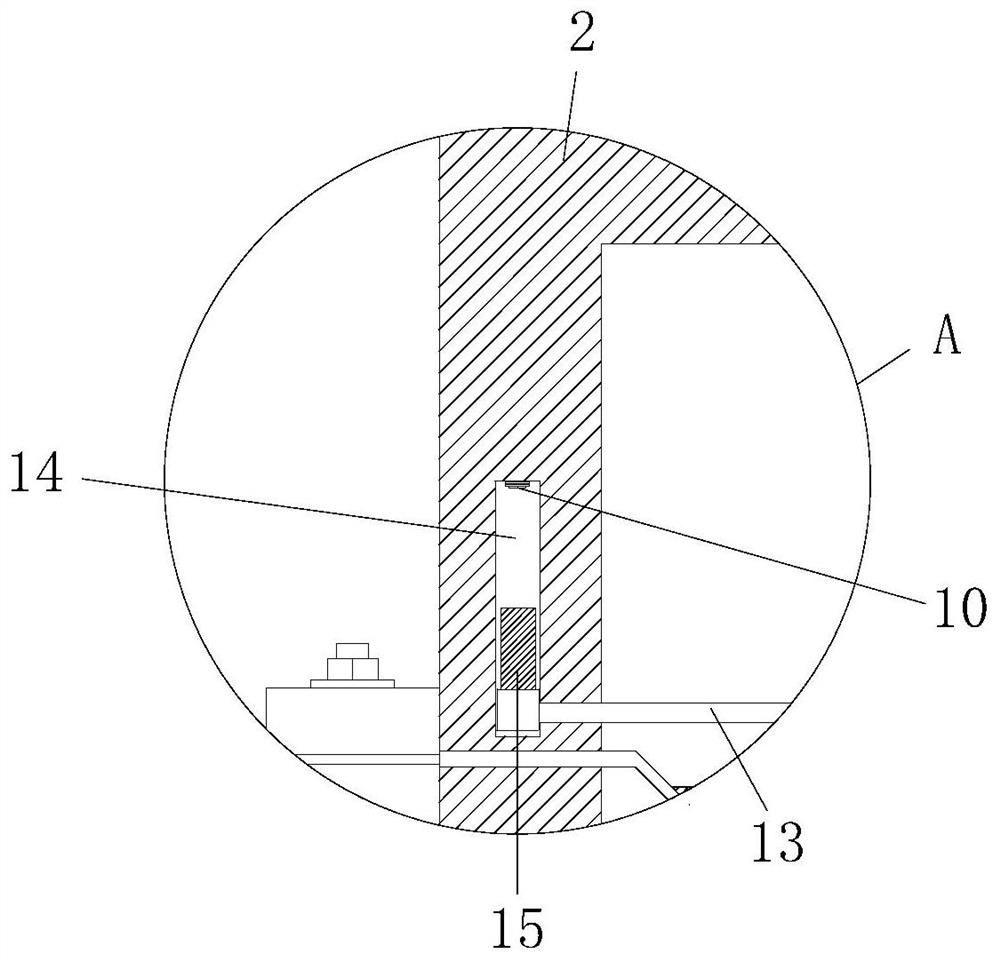

[0036] like Figure 4 As shown, in this embodiment, the guide block 15 is made of magnetic material, the fine adjustment chamber 14 is also provided with an iron slider 16, the sliding contact surface between the fine adjustment chamber 14 and the iron slider 16 is conical, and the distance sensor 10 is located on the lower end face of the iron slider 16, the side of the iron slider 16 is provided with a limit slot 18, the limit slot 18 is inserted with a limit insert rod 19, and the end of the limit insert rod 19 extends to the outside of the upper air chamber.

[0037] Specifically, the side of the upper air chamber is provided with a plurality of through grooves 21 that communicate with the fine adjustment chamber 14 , the limit insertion rod 19 penetrates through the through groove 21 , and the rod body between the limit insertion rod 19 and the through groove 21 is sleeved. There are telescopic springs 20 .

[0038] Specifically, an adjustment gap 17 is formed in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com