Novel plane articulated robot structure

A technology of planar joints and robots, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large inertia and small movable range of manipulators, and achieve compact and simple structure, reduce inertia, and facilitate arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated

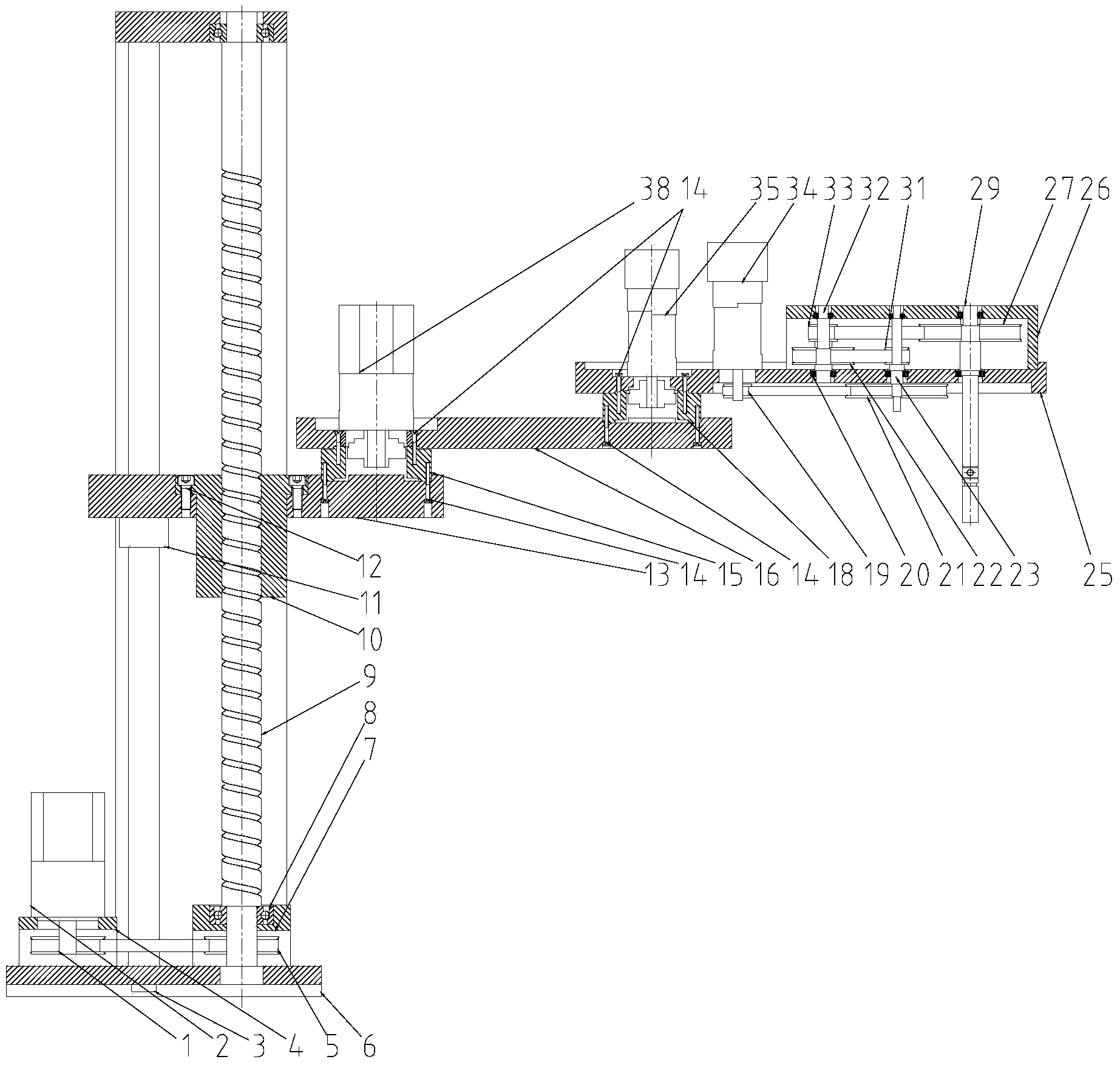

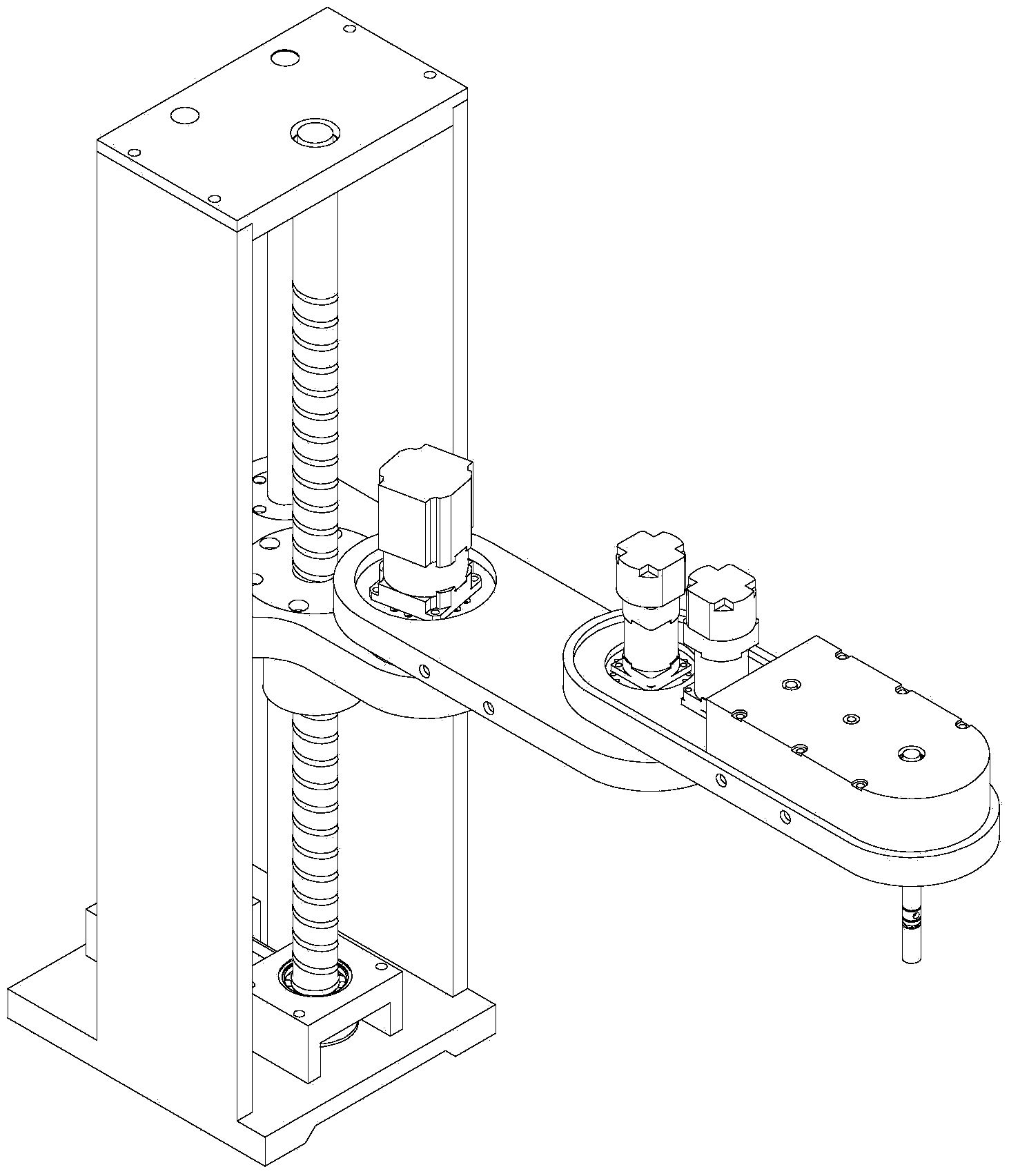

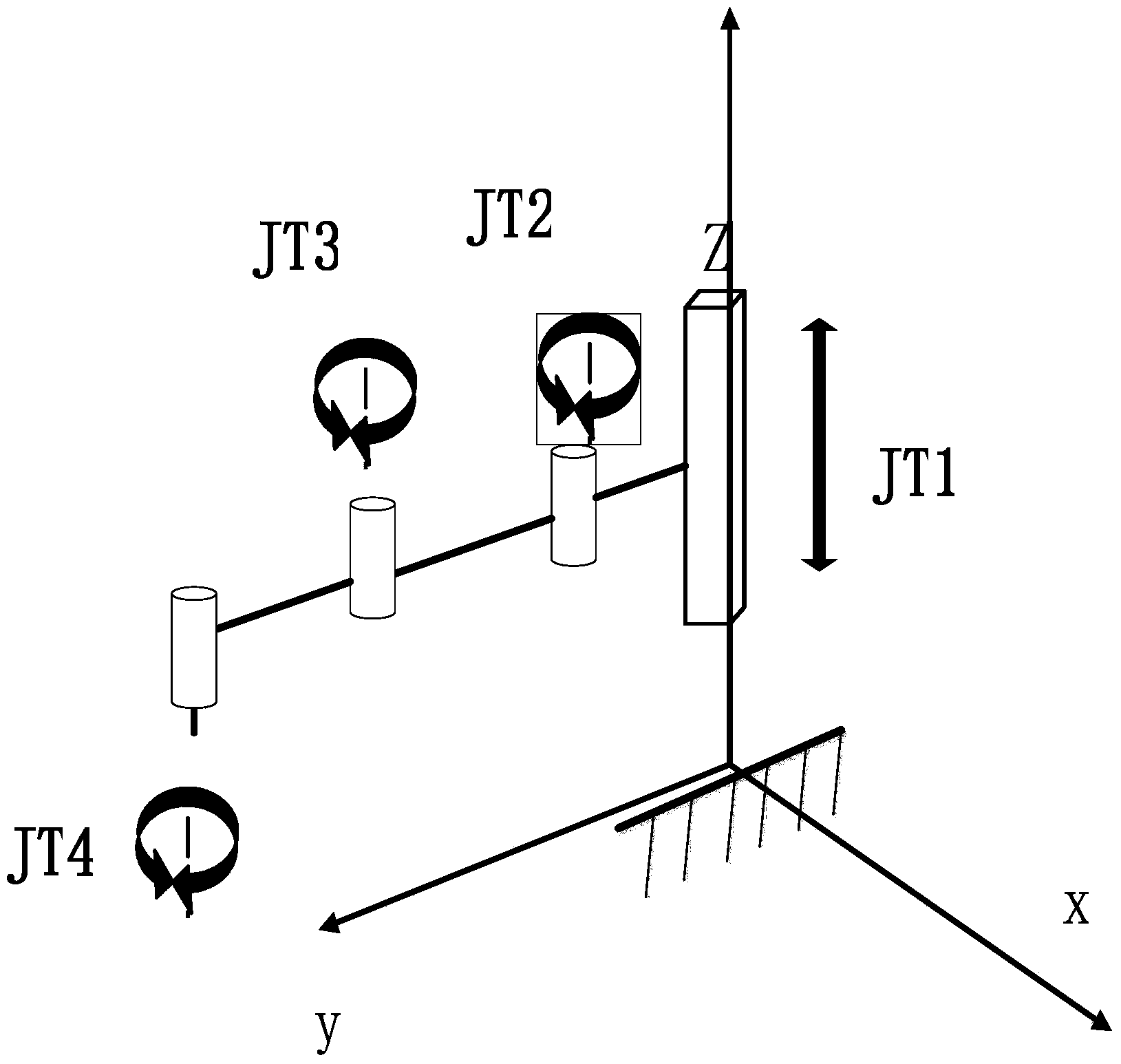

[0028] refer to Figure 1 to Figure 5 As shown, a novel planar articulated robot structure includes: a base 6 for support and shock absorption; an elevating base 13 that moves up and down along the Z-axis direction under the limit action of the screw rod 9 and the optical axis 3, the first Mechanical arm 16, which is rotatably mounted on the above-mentioned lifting base 13 with the X axis parallel to the above-mentioned Z axis as the rotation center; the second mechanical arm 25, which is rotatable with the Y axis parallel to the above-mentioned X axis as the rotation center Installed on the above-mentioned first mechanical arm 16; the working spindle 29, which is rotatably installed on the above-mentioned second mechanical arm 25 with the R axis parallel to the above-mentioned Y-axis as the rotation center; the cover 26, is installed on the second mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com