Parallel sorting robot driven by ropes tensioned through driven springs

A cable-driven and robotic technology, applied in the field of cable-driven parallel sorting robots, can solve the problems of difficulty in improving efficiency, large working space, and low cost, and achieve the effects of avoiding redundant drives, large working space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

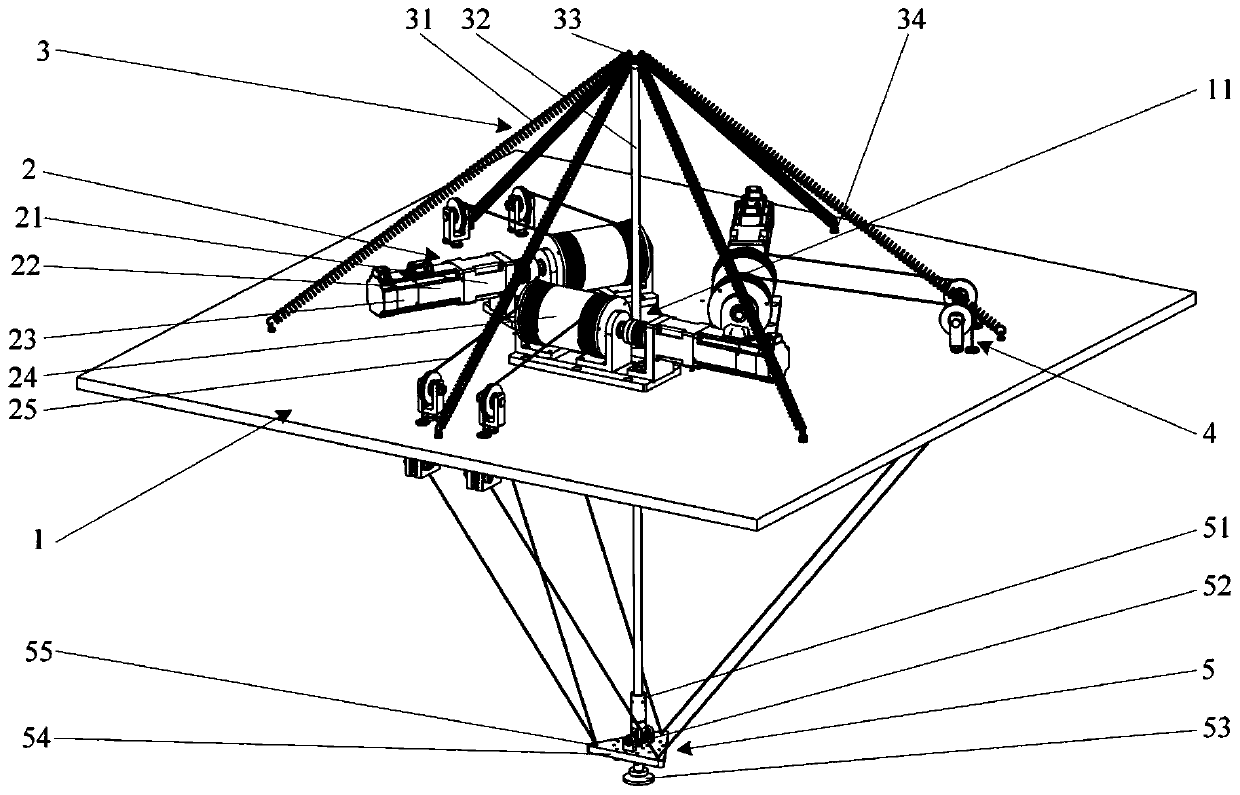

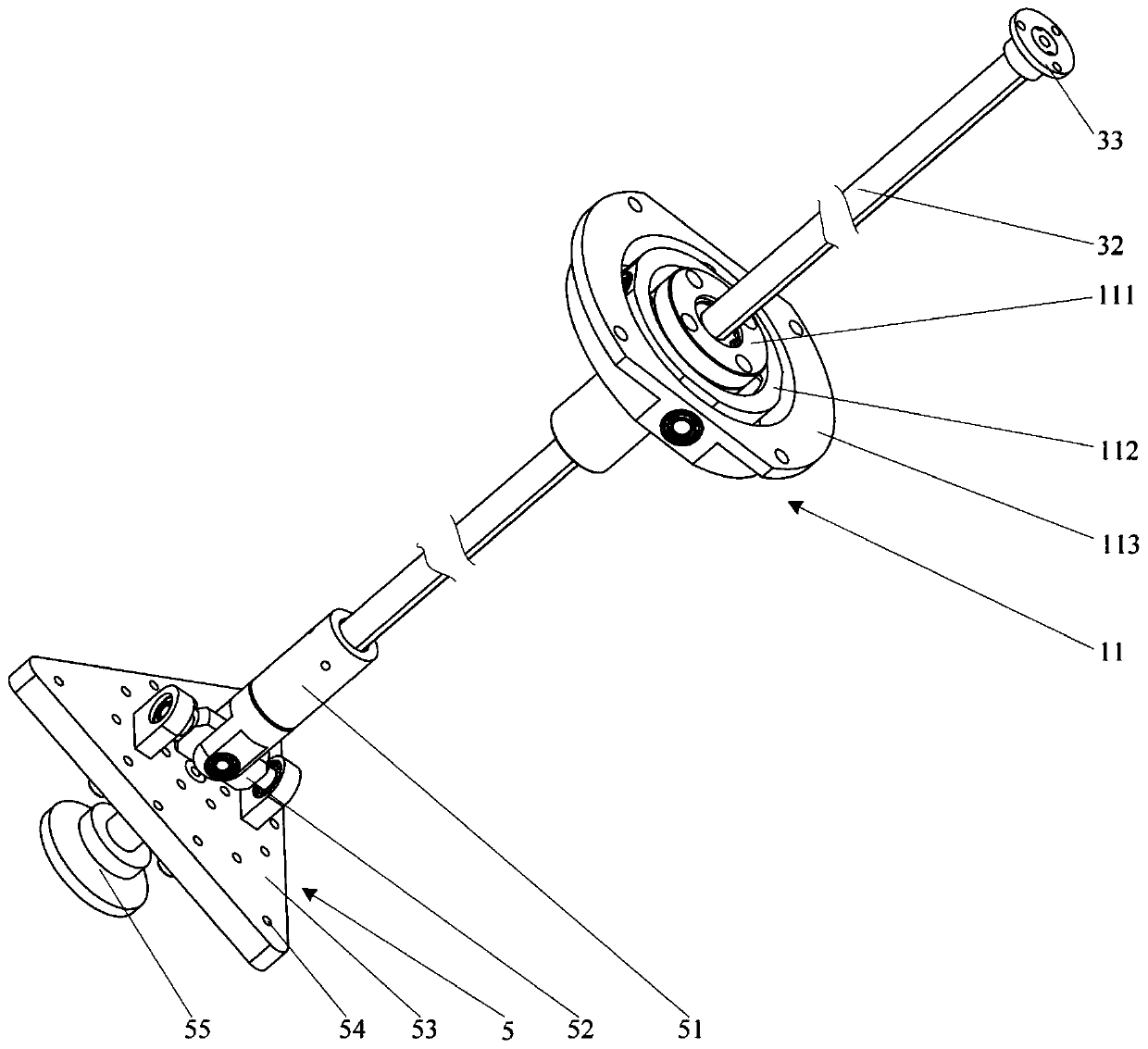

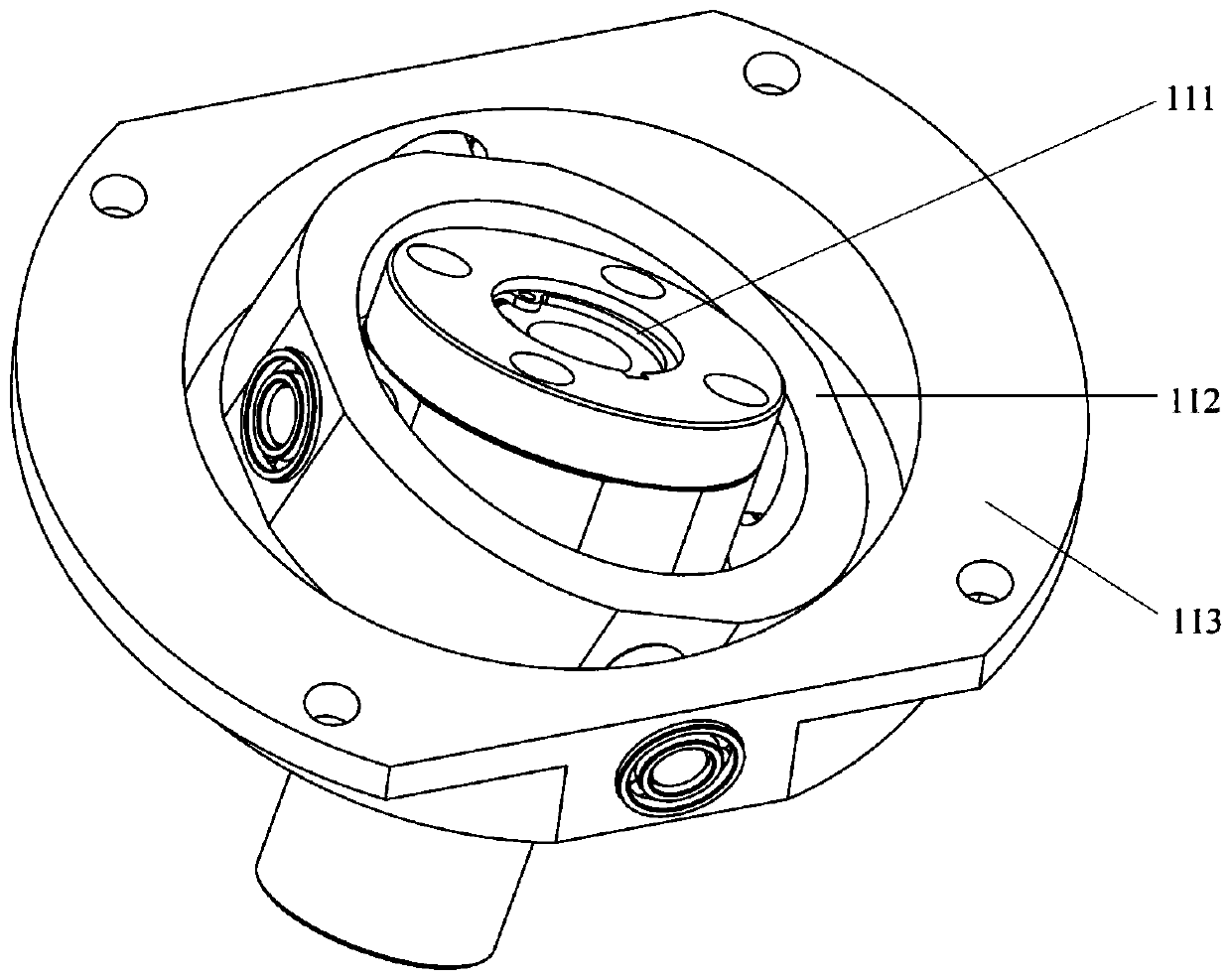

[0029] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0030] The cable-driven parallel mechanism (or cable parallel mechanism) is a special kind of parallel mechanism, and its driving branch chain is a flexible rope. The cable parallel mechanism inherits the high-load configuration advantages of the rigid parallel mechanism, and has the characteristics of small moment of inertia, large working space, low cost and easy reconfiguration of the cable drive. With the above advantages, the cable-parallel mechanism has become a hot spot in the field of robot research, and has been successfully applied in hoisting and handling, wind tunnel experiments, rehabilitation medicine, space positioning and virtual reality and other fields. Using ropes instead of rigid rods greatly reduces the inertia of the moving parts of the cable parallel mechanism, while avoiding the complicated hinge structure, which makes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com