Engineering vehicle walking driving hydraulic system

A travel drive, hydraulic system technology, applied in the direction of fluid pressure actuation device, servo motor, mechanical equipment, etc., can solve the problem of inability to meet the control characteristics, and achieve the effect of soft driving characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

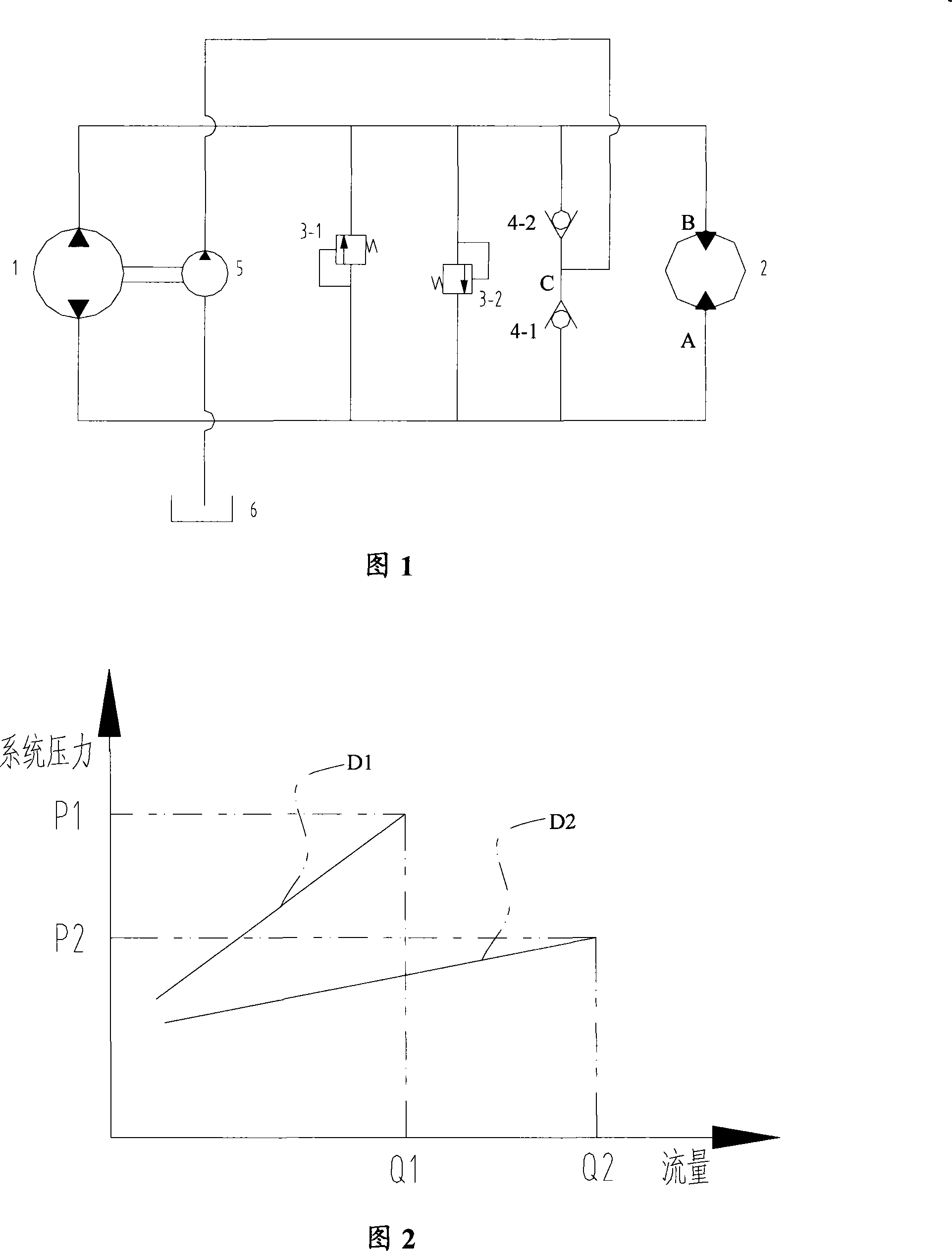

[0022] Please refer to FIG. 1 , which is a schematic diagram of the hydraulic principle of the driving hydraulic system of the construction vehicle provided by the first embodiment of the present invention.

[0023] As shown in the figure, the driving hydraulic system of the construction vehicle includes a two-way hydraulic pump 1 and a two-way hydraulic motor 2. Port A and reverse chamber oil port B. The two-way hydraulic motor 2 can rotate in two directions when the two-way hydraulic pump 1 provides hydraulic oil in different flow directions. The output characteristics of the two-way hydraulic motor 2 in the two rotation directions are consistent, but in actual use, the functions of the two rotation directions are different, wherein one rotation direction drives the vehicle forward, and the other rotation direction makes the vehicle reverse or brake. move. In order to distinguish the two oil ports of the two-way hydraulic motor, when the two-way hydraulic motor 2 is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com