Numerical control engraving and milling machine tool with linear motors

A linear motor, engraving and milling technology, applied in the direction of metal processing machinery parts, large fixed members, feeding devices, etc., can solve the problems of attenuation of positioning accuracy, low processing efficiency, low drag acceleration, etc., to reduce attenuation and improve processing High efficiency and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

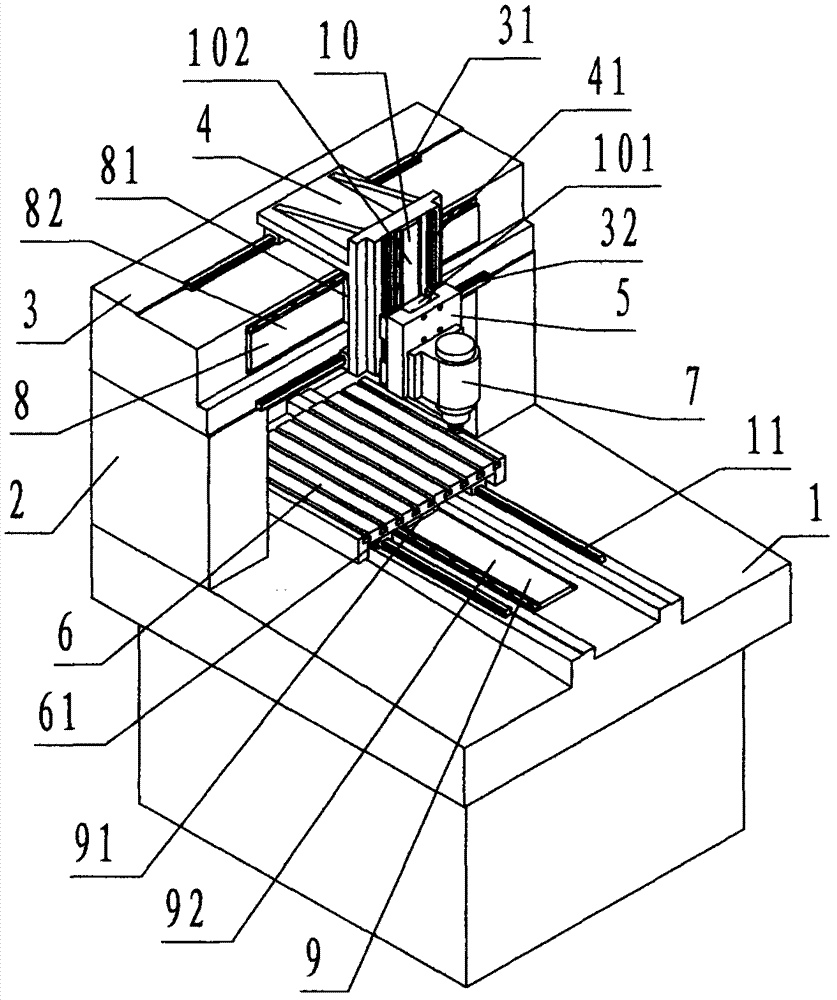

[0023] refer to figure 1 , a linear motor CNC engraving and milling machine tool of the present invention, comprising a bed 1, a column 2, a beam 3, an X-axis slide plate 4, a Z-axis slide plate 5, a workbench 6, a spindle motor 7, an X-axis linear motor 8, and a Y-axis Linear motor 9, Z-axis linear motor 10, wherein: the bed 1 is a hollow marble rectangular platform member, on the top of the bed 1, two parallel and upward The protruding cast iron slide rail is called the Y-axis slide rail 11;

[0024] The crossbeam 3 is a solid marble rectangular member, and the front and rear sides below the crossbeam 3 are respectively fixed and orthogonally connected with a vertically downward solid marble rectangular column 2, and the bottom of the column 2 is fixed and orthogonally connected to the bed 1. The front and rear sides on the left side of the top are fixedly connected by the bed 1, the column 2 and the beam 3 to form a marble gantry fixed body; The quality slide rail is call...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com