X-Y objective talbe

A stage and slider technology, applied in positioning devices, feeding devices, large fixed members, etc., can solve the problems of difficult to obtain high speed, increased weight, and difficult to obtain high speed at the same time, to achieve high moving flatness, High stopping accuracy and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

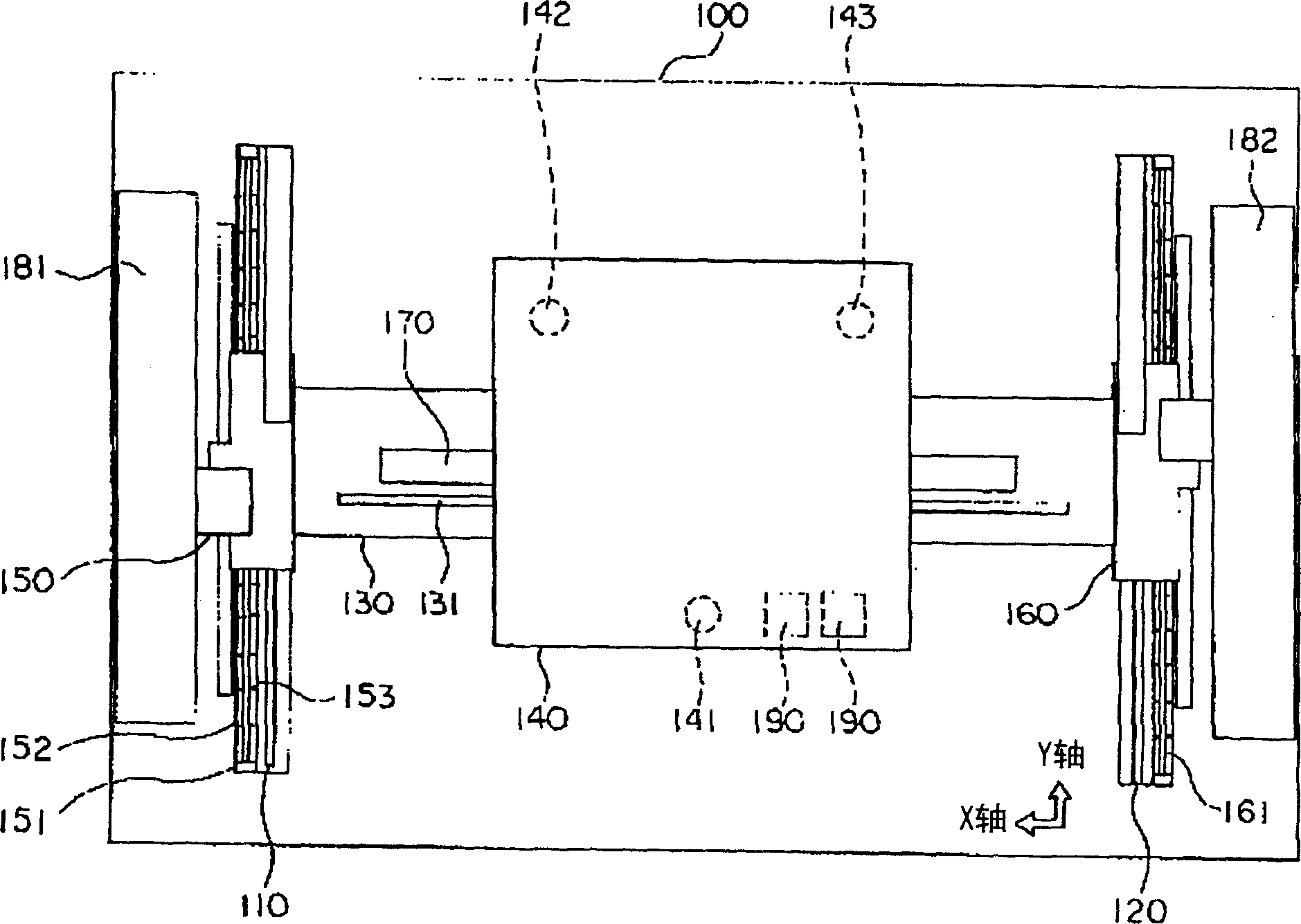

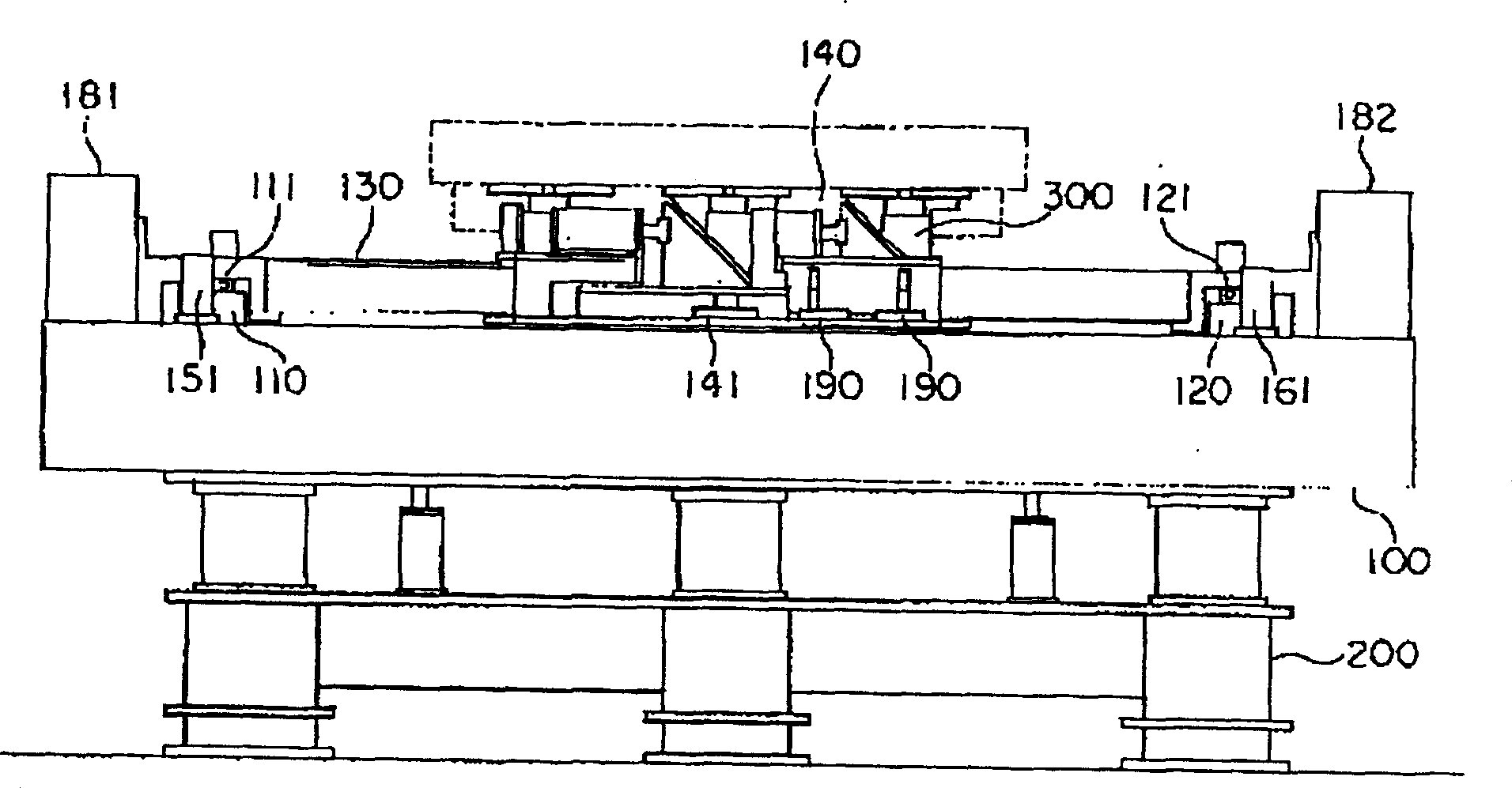

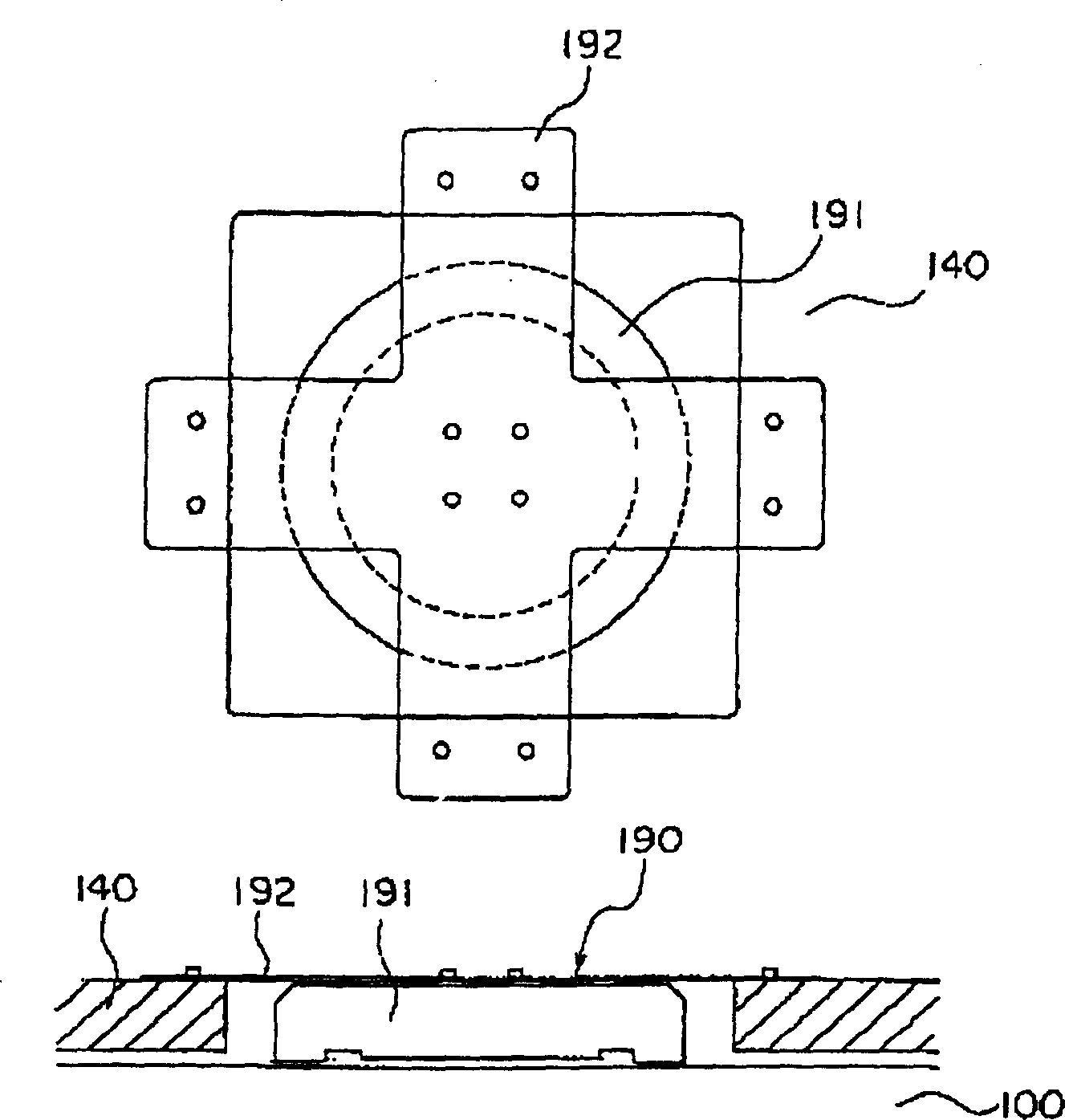

[0039] Below, refer tofigure 1 , figure 2 , to illustrate the preferred embodiment of the X-Y stage device according to the present invention.

[0040] exist figure 1 , figure 2 In the present X-Y stage device, the base 100 whose upper surface is surface-finished as a guide surface is fixed to the frame 200 . The base 100 is usually a stone slab. The fixing portion of the X-Y stage apparatus is the base 100 and guide rails 110 and 120 (first and second guide members) that are fixedly arranged on the base 100 at predetermined intervals. exist figure 1 , two directions of the X-axis and the Y-axis which are orthogonal to each other are shown. The guide rails 110 and 120 respectively extend in the Y-axis direction. In this X-Y stage device, the movable portion linearly guided in the Y-axis direction along the guide rails 11 and 120 is the Y slider 130 . The Y slider 130 is erected between the guide rails 110 and 120 , and the rolling bearings 111 and 121 are installed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com